You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Planning a new 383 build that is now going to be a 400

- Thread starter busterrm

- Start date

busterrm

solid fixture here in the forum

I am going to put it all in a plastic bag and tape it shut, have some stands and will zip tie the plastic bag to the stand and pull it out straight so I can keep the bag out of the fresh paint. This has been a big job getting the engine bay all cleaned and painted, but its going to look clean and fresh when the engine goes in. I have decided to put the front clip back on before the engine install, I want to see the whole thing together its been a job but its about done.

busterrm

solid fixture here in the forum

A tip for all you guys that are rattle can painters, during this project I have learned a few things. For top quality painting buy the VHT brand of aerosol paints, for moderate quality painting buy the Duplicolor brand, for not so important painting use Krylon. I have found out by experience that if your surface is well prepped VHT, if the directions on the can are followed, has the greatest possibility of not having runs, drips or errors. Its good paint and easy to spray on. Duplicolor is good also, but you have to take your time and watch your self, it will run and drip if you hurry. Krylon looks good when your done, but getting it there is harder, if you have all the time in the world and go slow and easy its okay in the end, but it has more tendency to run and drip more than VHT or Duplicolor. I think the difference lies in the consistency of the 3 different paints as they come out of the spray cans, VHT tends to be thicker and adheres to your surface easier, Duplicolor is not as thick but does adhere okay if you take your time, Krylon seems to be the thinnest of the 3 and that must be why it has more tendency of the 3 to easily run and drip. Just My Opinion! I have used all 3 brands and each has its own price, here in Wichita Falls VHT is 8.99 a can, Duplicolor is 7.99 a can, Krylon is 5.99 a can. I just wanted to put this out there and let everyone decide for theirself.

yeah theres a big difference in brand ,cost and quality, in off the shelf paint,

but Id also point out that most of the larger professional automotive paint supply stores will , if asked supply you with,(for the right price of course)

custom manufacture spray cans filled with Original Manufacturer correct factory color code,

matching paint but your typically pay $20 a can

but Id also point out that most of the larger professional automotive paint supply stores will , if asked supply you with,(for the right price of course)

custom manufacture spray cans filled with Original Manufacturer correct factory color code,

matching paint but your typically pay $20 a can

Last edited:

8

87vette81big

Guest

I really like the VHT Paint line also Bob.

Best option if you can't afford Professional Autobody paint.

And their High Temp Paints do work nice on exhaust parts.

When you can't afford Ceramic Jet Hot Coatings.

Best option if you can't afford Professional Autobody paint.

And their High Temp Paints do work nice on exhaust parts.

When you can't afford Ceramic Jet Hot Coatings.

busterrm

solid fixture here in the forum

I posted a thread on another site yesterday, I couldn't remember if I posted a thread about my new engine. So I posted a thread with a basic build sheet. I am thinking I shouldn't have, that site has a bad habit of different members bickering and banging a person's decisions. I was kinda told it would overheat because its a 400, that I am wrong to use 5.7 rods, and also told it isn't going to make the hp/tq I am estimating, I know it won't be exact, but I expect good things from the engine. Oh well, not all sites are a good place for support.

8

87vette81big

Guest

Tell them to Kiss It Bob.

Without a Power adder they are Bench Racing I am sure eleswhere.

Rear Diff Gears....Drag Race Set if you please, & dialed in Combo as Grumpy taught us.

Hellcats Blown Away.

Without a Power adder they are Bench Racing I am sure eleswhere.

Rear Diff Gears....Drag Race Set if you please, & dialed in Combo as Grumpy taught us.

Hellcats Blown Away.

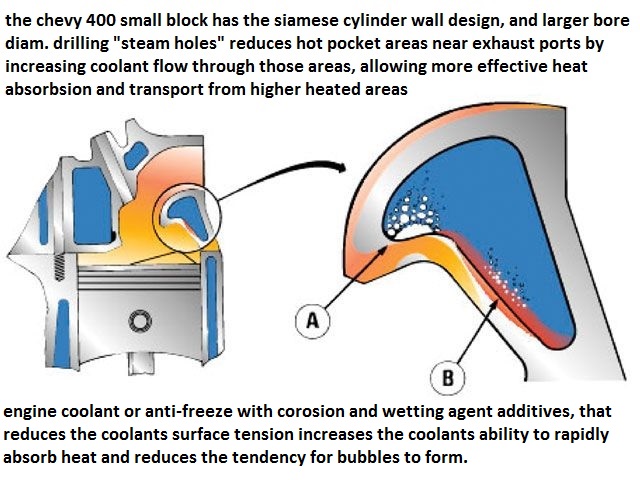

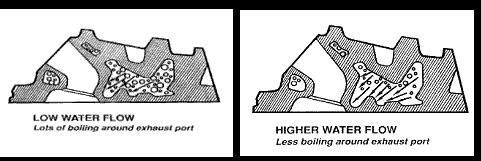

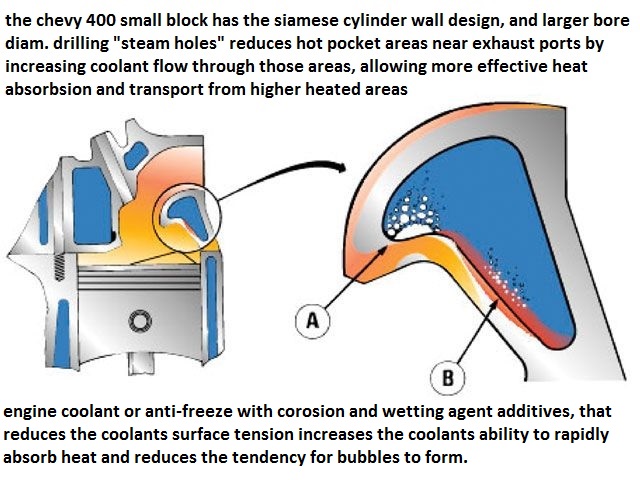

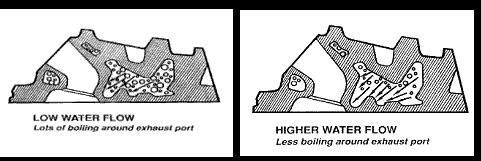

400 sbc engines have a reputation for running hotter than the average SBC thats only partially deserved

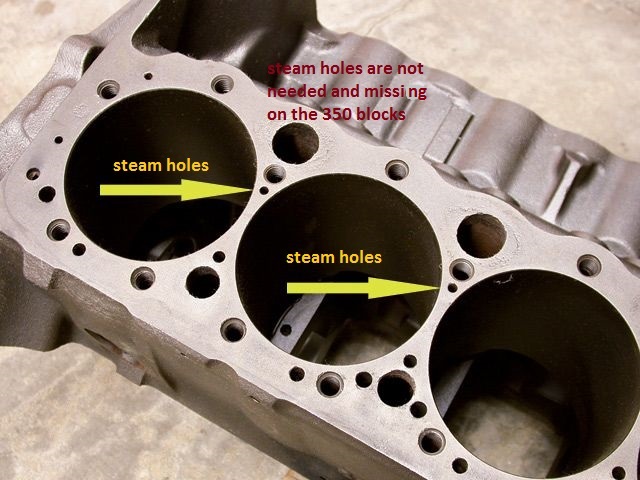

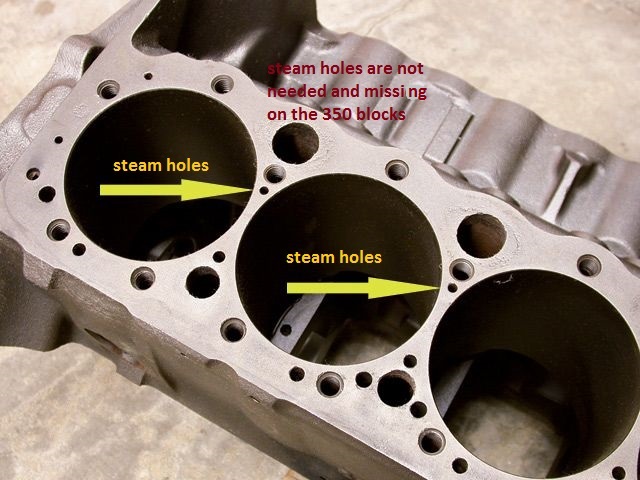

the 400 SBC used SIAMESE CYLINDER WALLS, and the average hot rodder , looking at the larger bore 400 block, only looked at the potential for increased displacement, and never put much thought into the engineering required to effectively use that increased bore diam. thus the fact the Siamese block design meant the coolant can't pass between the cylinders so heat does tend to have a very slightly lower surface area to allow coolant to absorb the heat generated from., for decades guys swapped the better flowing fuelie heads onto the larger displacement 400 based engines without adding the additional coolant steam holes, to help the Siamese cylinder wall block design, cool more effectively , and forget that if you increase compression, and produce significantly more horse power that power increase is the result of burning MORE FUEL BURNT FASTER, AT HIGHER AVERAGE RPMS, which, always results in producing higher average heat levels as a by product.

theres no free lunch , if you increase a 400 sbc power from a stock 185 hp two barrel engine that might have 9:1 compression that rarely saw 4500 rpm, into lets say a 406 SBC with better heads, 11:1 compression that, engine could easily, produce 470 hp , your going to reasonably expect nearly double the heat energy being produced.

a KNOWLEDGEABLE hot rodder, willing to think through the required modifications will have no trouble keeping a 400 SBC based engine cool

ONCE COOLANT BOILS it lost the full ability to absorb heat as partial direct contact with the metal surface is partially lost, one reason cooling systems are pressurized is to increase the boiling point threshold

The 5.7" rods vs the stock 5.565 " rods are a slight improvement in rod angularity and 6" rods would be slightly better but even the shorter rods work reasonably well if correctly clearanced and the rotating assembly balance as long as the rpms keep the piston speeds reasonable for the components being used (GENERALLY under 6200rpm)

READ THE LINKS AND SUB LINKS CAREFULLY

the cylinder heads, need to have extra "STEAM HOLES" drilled this allows coolant to more easily flow from the areas more prone to low coolant flow rates.

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/

use the correct sealants

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-1171

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12528

the 400 SBC used SIAMESE CYLINDER WALLS, and the average hot rodder , looking at the larger bore 400 block, only looked at the potential for increased displacement, and never put much thought into the engineering required to effectively use that increased bore diam. thus the fact the Siamese block design meant the coolant can't pass between the cylinders so heat does tend to have a very slightly lower surface area to allow coolant to absorb the heat generated from., for decades guys swapped the better flowing fuelie heads onto the larger displacement 400 based engines without adding the additional coolant steam holes, to help the Siamese cylinder wall block design, cool more effectively , and forget that if you increase compression, and produce significantly more horse power that power increase is the result of burning MORE FUEL BURNT FASTER, AT HIGHER AVERAGE RPMS, which, always results in producing higher average heat levels as a by product.

theres no free lunch , if you increase a 400 sbc power from a stock 185 hp two barrel engine that might have 9:1 compression that rarely saw 4500 rpm, into lets say a 406 SBC with better heads, 11:1 compression that, engine could easily, produce 470 hp , your going to reasonably expect nearly double the heat energy being produced.

a KNOWLEDGEABLE hot rodder, willing to think through the required modifications will have no trouble keeping a 400 SBC based engine cool

ONCE COOLANT BOILS it lost the full ability to absorb heat as partial direct contact with the metal surface is partially lost, one reason cooling systems are pressurized is to increase the boiling point threshold

The 5.7" rods vs the stock 5.565 " rods are a slight improvement in rod angularity and 6" rods would be slightly better but even the shorter rods work reasonably well if correctly clearanced and the rotating assembly balance as long as the rpms keep the piston speeds reasonable for the components being used (GENERALLY under 6200rpm)

READ THE LINKS AND SUB LINKS CAREFULLY

the cylinder heads, need to have extra "STEAM HOLES" drilled this allows coolant to more easily flow from the areas more prone to low coolant flow rates.

http://garage.grumpysperformance.com/index.php?threads/400-sbc-steam-holes-posted-by-dennyw.2991/

http://garage.grumpysperformance.com/index.php?threads/thoughts-on-cooling.149/

http://garage.grumpysperformance.com/index.php?threads/how-the-cooling-system-works-basics.853/

http://garage.grumpysperformance.co...ing-system-flow-rates-and-heat-transfer.9880/

http://garage.grumpysperformance.com/index.php?threads/water-wetter.2140/

use the correct sealants

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-1171

http://garage.grumpysperformance.co...venting-leaky-head-bolts-studs.50/#post-12528

Last edited:

busterrm

solid fixture here in the forum

Twiddling my thumbs, we have had rain the last few days, so I am at a standstill on the nova. I got the firewall all sealed up and ready for a good pressure washing. Kinda excited to get the firewall painted and get front clip back on, I want to see my engine bay all fresh and clean. Oh well, spose to dry up monday and I will get it done.

busterrm

solid fixture here in the forum

Still raining here in wichita falls, I did get out to pressure wash the firewall yesterday and was going to paint the firewall. But, yesterday about noon right about the time I was going to wash the firewall, some goober slammed into a utility pole about a block away from my house. It took out power in this whole area of town, it took 6 hrs to replace the pole and get the power back up. That took the whole window I had to clean and paint the firewall. I got it washed before dark, and now the rain has returned, I might get it painted tomorrow, crossing my fingers.

busterrm

solid fixture here in the forum

We had a break in the storm front, winds changed and it moved out. So it warmed up so I went out and dried off everything and painted the firewall, let it dry for an hour and slipped the front clip back on the car. Its just sitting there right now, I will have to get out the shims and adjust the finders to get the body lines to match up and then bolt it down permanent. I will get some pictures of it tomorrow.

8

87vette81big

Guest

Looks Great Bob !

A Big Improvent from just a few weeks ago.

A Big Improvent from just a few weeks ago.

JimmyDuncan

Well-Known Member

Looking good!

Loves302Chevy

"One test is worth a thousand expert opinions."

I never thought about putting a spring in there. Great idea.

busterrm

solid fixture here in the forum

Did some on the engine yesterday, I wasn't real pleased with the surface on the heads. I remembered a video I saw on YouTube, so I used it to see if it would work for me. I got a slab of marble from a friend that is a contractor on loan for my purpose, and used 3m adhesive and stuck sand paper to it. I used 80, 150, and 220, for my project. There is a square recess on each end of the heads, I took a depth reading with a micrometer for reference. I laid each head flat and using even pressure I slid the head back and forth across a 36 inch section of first the 80 grit. I did this to both heads, then took a measurement once I was satisfied with the surface, I did it on the other head until I had removed the same amount from both heads. 80 grit I took off .002, 150 grit I took off .001, and 220 grit I took off .001 for the final finish, and a total .004. If .006 equals 1cc in Combustion Chamber volume, .004 equals .67 cc, so my chamber is 63.33 cc's. I fed that into calculator and my SCR is now 10.67, and DCR is 8.28. Am I right on the CC's, .006 = 1cc of volume in a 64cc chamber heads? Anyway here are two shots of finished surfaces of the two heads.

I am about to reorder studs for the heads, when I had them on the first time I wasn't satisfied how the bolts torqued. Remembering a previous engine, and how they torqued very evenly, I am considering using studs instead of bolts.

I am about to reorder studs for the heads, when I had them on the first time I wasn't satisfied how the bolts torqued. Remembering a previous engine, and how they torqued very evenly, I am considering using studs instead of bolts.

8

87vette81big

Guest

Nice work Bob.

Looks Great.

Looks Great.

busterrm

solid fixture here in the forum

Thanks Brian!Nice work Bob.

Looks Great.