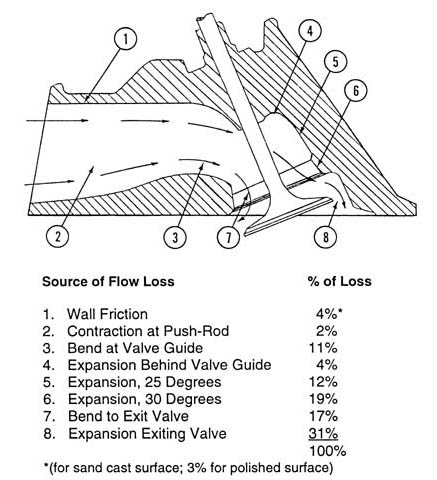

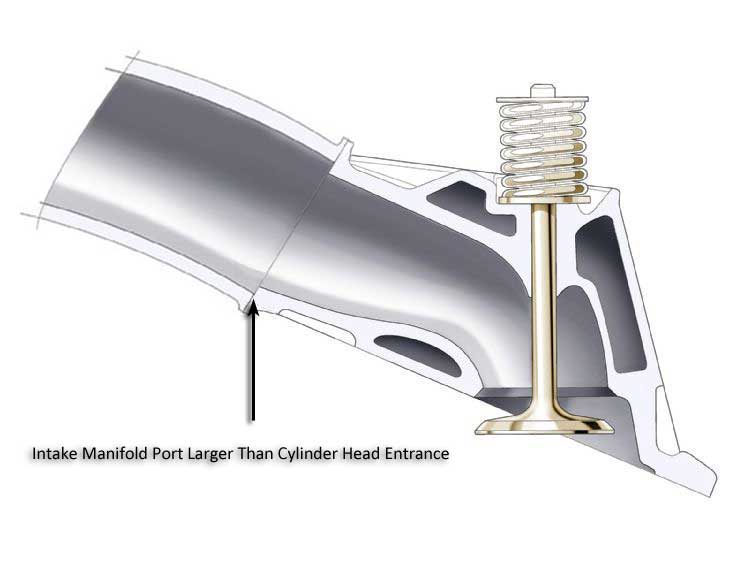

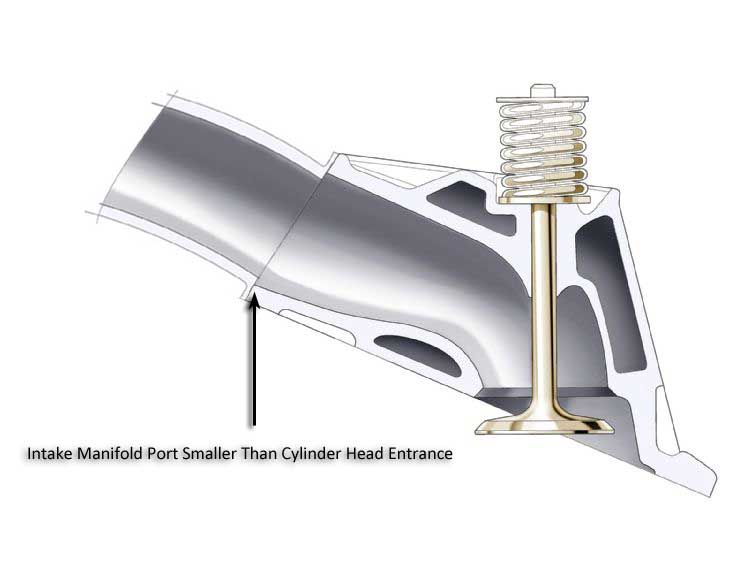

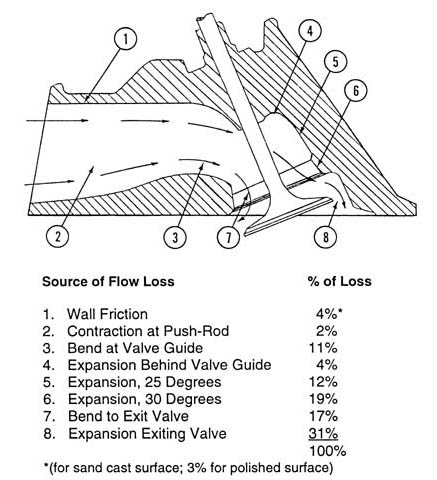

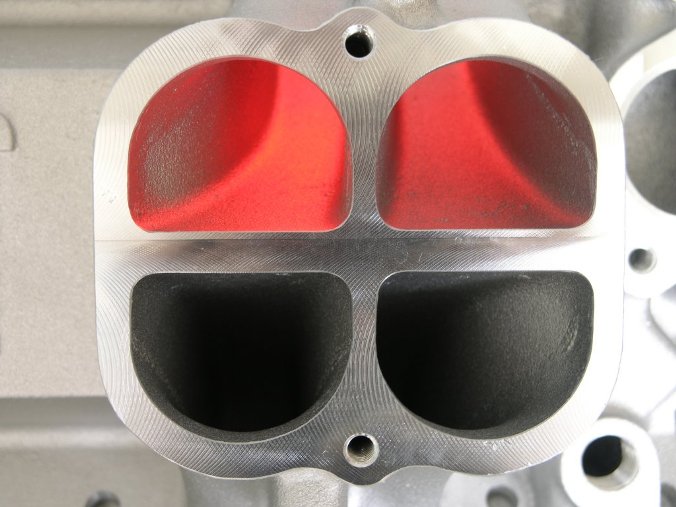

the object of port matching an intake to the cylinder heads is to increase flow and decrease the potential restriction a ledge in the port runners or mismatch in port size or location may cause to air flow rates into the cylinders

(1)use machinist BLUE , to paint the area around each port in the intake to cylinder head mating surface,

http://www.highlandwoodworking.com/brow ... 4-oz..HTML

http://www.highlandwoodworking.com/brow ... rosol.html

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

viewtopic.php?f=27&t=1831&p=9240#p9240

viewtopic.php?f=52&t=4664&p=12600#p12600

http://www.cis.udel.edu/~davis/z28/buildup/plenum/

http://www.austinthirdgen.org/index.php?pid=21

let it dry, then after aligning the gasket ,use a machinists pick,to carefully and accurately outline the gasket entrance,edge on the intake mating surface around the existing port , the area up to that scribed line needs to be cut out and smoothly blended back into the runner as far as is practical

http://www.harborfreight.com/cpi/ctaf/d ... mber=93514

(2)

get an intake gasket from a quality manufacturer to use as a pattern and use the bolt holes as your alignment guide points

you place the intake gasket to use as a pattern then you use a die grinder

http://www.harborfreight.com/cpi/ctaf/d ... mber=99698

THESE WORK OK, (BASICALLY CHEAP THROW AWAY DIE GRINDERS< BUT YOU'LL FREQUENTLY GET 3-4 intakes done before they get pitched in the trash)

with a high speed carbide burr

http://www.amazon.com/Style-degree-Radi ... B0007OTCQC

(frequently spray cutter with WD40) to prevent aluminum from sticking to the burr blades

http://www.youtube.com/watch?v=4xhgGux7d9w

http://www.youtube.com/watch?v=cFrPps-KJy8

http://image.mustangandfords.com/f/9194212+w750+st0

/mufp_0610_19_z+engine_bulding_mistakes+port_matching.jpg

http://www.circletrack.com/techarticles ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://theamcpages.com/documents/engine ... -ports.doc

http://www.maximumraceengines.com/intak ... rting.html

http://www.automedia.com/Port_Matching_ ... 040801pm/2

http://www.allpar.com/fix/holler/porting.html

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.automedia.com/Port_Matching_ ... 040801pm/1

http://performanceolds307.tripod.com/id29.html

http://www.mustangandfords.com/techarti ... r_arm.html

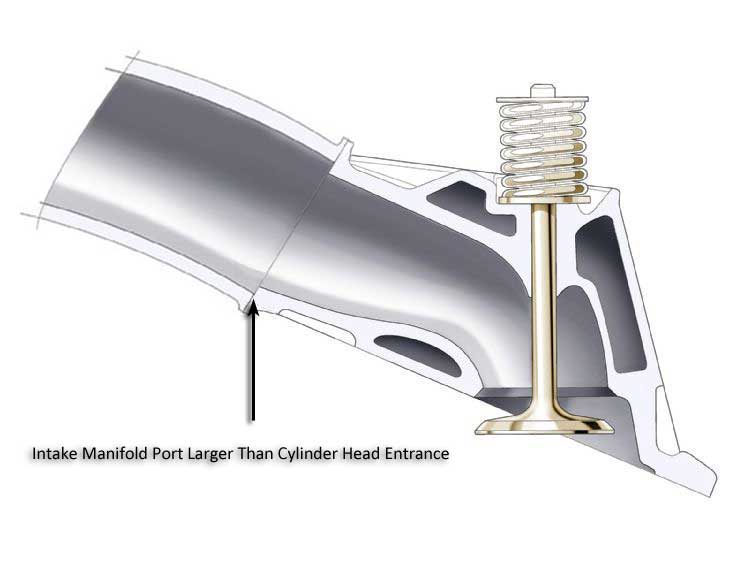

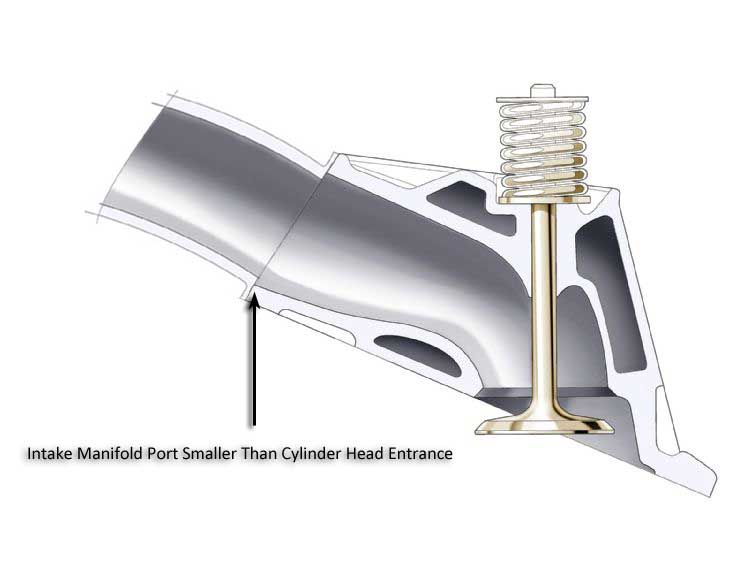

Not Port Matching Intake Manifold, Heads, Gaskets

Engine Building Mistakes Port Matching

"Mark Jeffrey of Trans Am Racing mentioned this one. We don't understand this mistake because it's so obvious. Never assume cylinder-head and intake-manifold ports automatically line up, because they don't-not even when cylinder heads and intake manifolds are from the same manufacturer. Regardless of the performance you are seeking, always port-match cylinder heads and intake manifold. Port-match using gaskets on both manifold and heads. When port-size difference is significant, consider the selection of more compatible heads and manifold. Large manifold ports and small cylinder head ports (and vice versa) don't make sense because it robs power and creates disturbed airflow through the runners."

viewtopic.php?f=52&t=462

viewtopic.php?f=27&t=408&p=688#p688

in many cases the flow increase that results is small, but in a few cases significant gains can be had, in many cases even thought the gains are small its well worth doing simply because the cost and time required is fairly low and gains of 2-4 horsepower are common, in a few cases youll find badly mis-matched ports that the process can, clear up and gaining 5-8 hp or more is the results

http://www.rodandcustommagazine.com/tec ... index.html

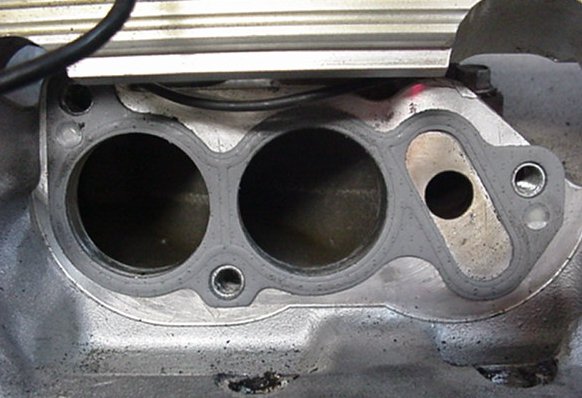

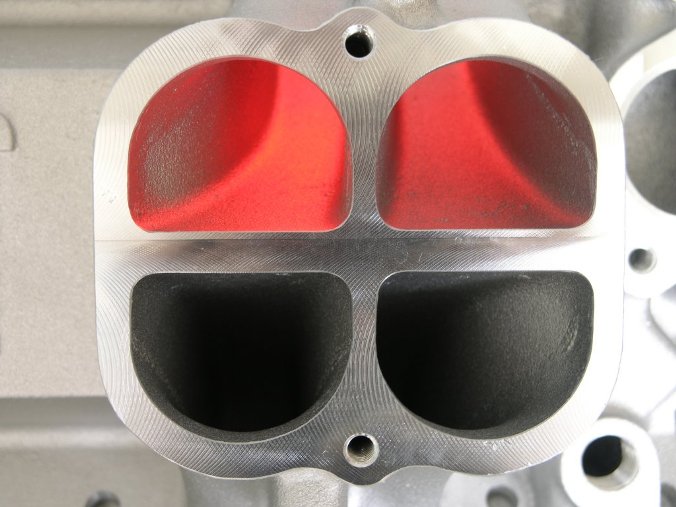

stock un-ported runner entrances

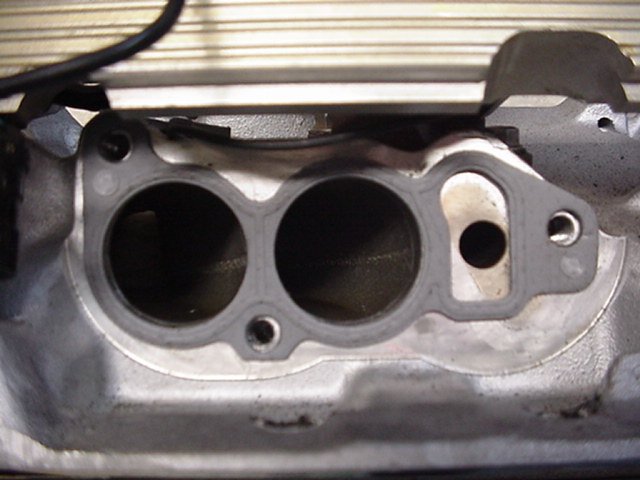

porting helps flow significantly

(1)use machinist BLUE , to paint the area around each port in the intake to cylinder head mating surface,

http://www.highlandwoodworking.com/brow ... 4-oz..HTML

http://www.highlandwoodworking.com/brow ... rosol.html

PORT MATCHING THE INTAKE RUNNER EXIT TO THE CYLINDER HEAD PORT ENTRANCE USUALLY HELPS REDUCE RESTRICTIONS TO FLOW RATES, AND REDUCES FUEL/AIR DISTRIBUTION ISSUES

viewtopic.php?f=27&t=1831&p=9240#p9240

viewtopic.php?f=52&t=4664&p=12600#p12600

http://www.cis.udel.edu/~davis/z28/buildup/plenum/

http://www.austinthirdgen.org/index.php?pid=21

let it dry, then after aligning the gasket ,use a machinists pick,to carefully and accurately outline the gasket entrance,edge on the intake mating surface around the existing port , the area up to that scribed line needs to be cut out and smoothly blended back into the runner as far as is practical

http://www.harborfreight.com/cpi/ctaf/d ... mber=93514

(2)

get an intake gasket from a quality manufacturer to use as a pattern and use the bolt holes as your alignment guide points

you place the intake gasket to use as a pattern then you use a die grinder

http://www.harborfreight.com/cpi/ctaf/d ... mber=99698

THESE WORK OK, (BASICALLY CHEAP THROW AWAY DIE GRINDERS< BUT YOU'LL FREQUENTLY GET 3-4 intakes done before they get pitched in the trash)

with a high speed carbide burr

http://www.amazon.com/Style-degree-Radi ... B0007OTCQC

(frequently spray cutter with WD40) to prevent aluminum from sticking to the burr blades

http://www.youtube.com/watch?v=4xhgGux7d9w

http://www.youtube.com/watch?v=cFrPps-KJy8

http://image.mustangandfords.com/f/9194212+w750+st0

/mufp_0610_19_z+engine_bulding_mistakes+port_matching.jpg

http://www.circletrack.com/techarticles ... index.html

http://www.hotrod.com/techarticles/engi ... index.html

http://theamcpages.com/documents/engine ... -ports.doc

http://www.maximumraceengines.com/intak ... rting.html

http://www.automedia.com/Port_Matching_ ... 040801pm/2

http://www.allpar.com/fix/holler/porting.html

http://racingsecrets.com/speedtalk_head_porting.shtml

http://www.automedia.com/Port_Matching_ ... 040801pm/1

http://performanceolds307.tripod.com/id29.html

http://www.mustangandfords.com/techarti ... r_arm.html

Not Port Matching Intake Manifold, Heads, Gaskets

Engine Building Mistakes Port Matching

"Mark Jeffrey of Trans Am Racing mentioned this one. We don't understand this mistake because it's so obvious. Never assume cylinder-head and intake-manifold ports automatically line up, because they don't-not even when cylinder heads and intake manifolds are from the same manufacturer. Regardless of the performance you are seeking, always port-match cylinder heads and intake manifold. Port-match using gaskets on both manifold and heads. When port-size difference is significant, consider the selection of more compatible heads and manifold. Large manifold ports and small cylinder head ports (and vice versa) don't make sense because it robs power and creates disturbed airflow through the runners."

viewtopic.php?f=52&t=462

viewtopic.php?f=27&t=408&p=688#p688

in many cases the flow increase that results is small, but in a few cases significant gains can be had, in many cases even thought the gains are small its well worth doing simply because the cost and time required is fairly low and gains of 2-4 horsepower are common, in a few cases youll find badly mis-matched ports that the process can, clear up and gaining 5-8 hp or more is the results

http://www.rodandcustommagazine.com/tec ... index.html

stock un-ported runner entrances

porting helps flow significantly