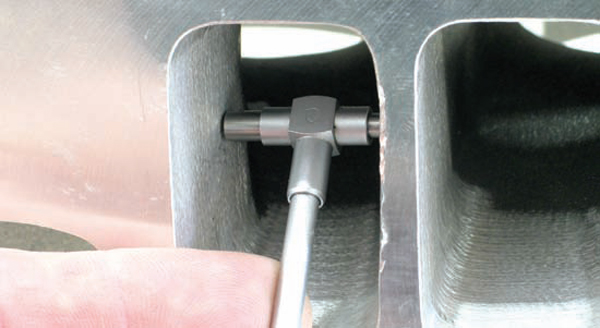

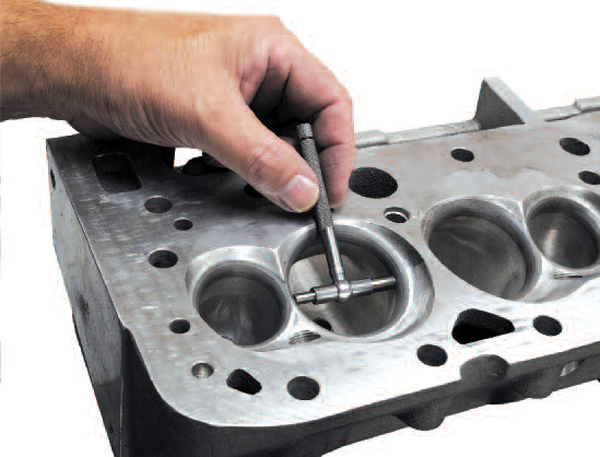

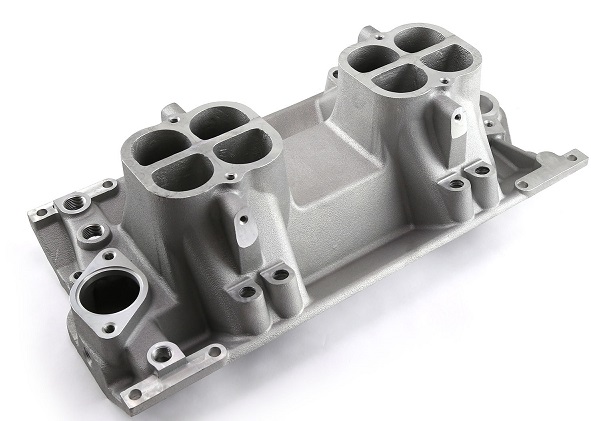

I'm starting this thread here to talk about the Pro Flow XT for small block chevy. I plan on installing it on a 355 next summer. I chose the XT because of all the performance EFI intake options on the market today, I think the XT shows the most overall potential for combining top end power and midrange torque. While the overall design of the XT is good, the weakness I see is the small runner exits. Mounting it on cyl heads that are port matched to a felpro 1205 gasket(2.09 x 1.28) will leave alot of material inside the gasket openings all the way around each intake port. This could be a pretty big choke point on heads that flow well. My heads are ported Trickflow twisted wedge G2s that flow 270cfm.

I spoke with Eddy tech just to get their thoughts on it. The guy told me that the small runner exit is intended to increase velocity in the flow range of a street driven engine. That makes since except that if the head's intake port is considerably larger than the runner exit, that velocity is going to drop off hard right where it needs to be strongest for fuel atomization. When I brought up extrude honing to smooth the interior casting, I was also told that the rough casting is there to encourage swirl and tumble of the air through the runners. Now maybe I have learned this wrong over the decades that I've done this stuff but I've become pretty sure that the tumble and swirl needs to take place starting at the back of the intake valve and into the chamber. Swirl and tumble in the runners sounds alot like flow killing turbulence.

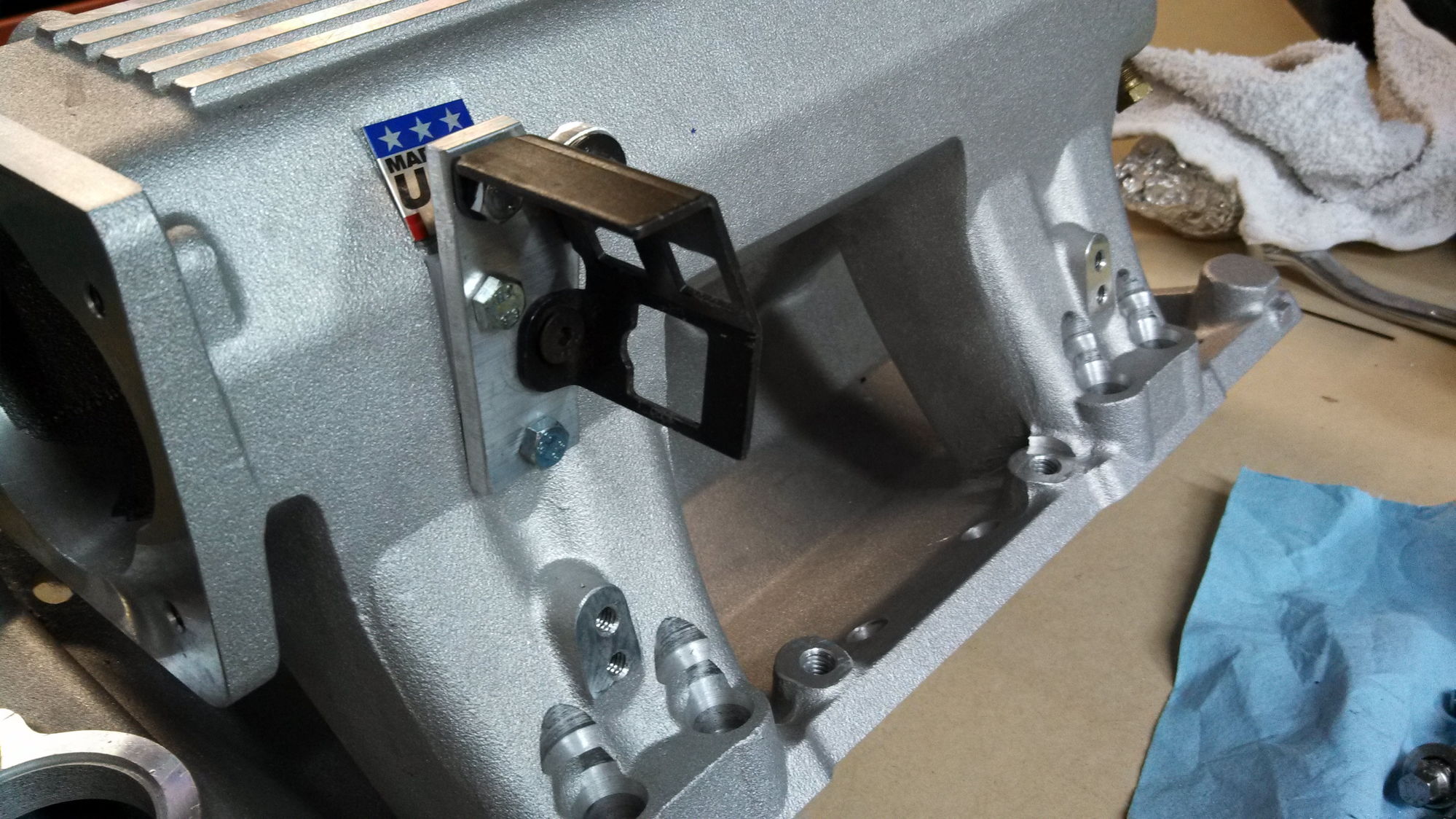

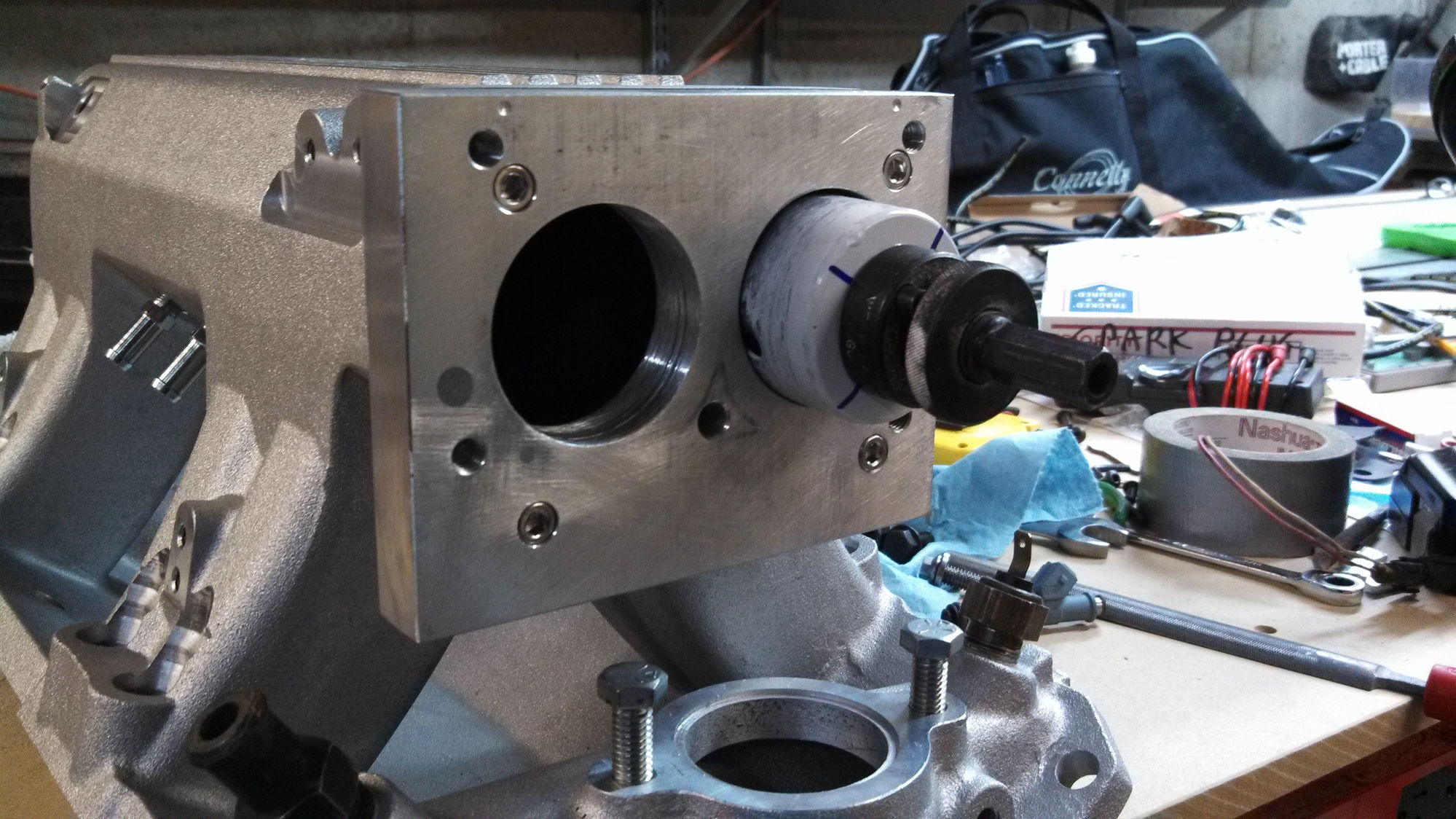

At any rate, I still plan to work this unit over before it goes on. After pricing extrude honing, I'm thinking of going with my other option of having the top of the plenum cut off and hand finishing the runners and runner entries, surfacing the plenum. I may even add a small amount of volume to the plenum when it goes back together. It appears that the piece was designed primarily for street use for stock or slightly larger ports. To support my heads and cam and make my power goal of 460hp at about 6,300, I think it will need to flow a little more, even at the cost of a slight bit of throttle response and low end torque. My 3,500 stall converter and gears will help cover the low end side anyway.

BTW, I'm here to air my ideas as a long time pro mechanic/ hobbiest engine builder. I hope to start a discussion and welcome any and all opinions and feedback on this intake manifold and my ideas for it.

Sorry, tried to attach some photos of the piece for those unfamiliar with it. Seems my photos are too large.

Again, this is the Edelbrock Pro Flow XT EFI tunnel ram P/N 7137.

I spoke with Eddy tech just to get their thoughts on it. The guy told me that the small runner exit is intended to increase velocity in the flow range of a street driven engine. That makes since except that if the head's intake port is considerably larger than the runner exit, that velocity is going to drop off hard right where it needs to be strongest for fuel atomization. When I brought up extrude honing to smooth the interior casting, I was also told that the rough casting is there to encourage swirl and tumble of the air through the runners. Now maybe I have learned this wrong over the decades that I've done this stuff but I've become pretty sure that the tumble and swirl needs to take place starting at the back of the intake valve and into the chamber. Swirl and tumble in the runners sounds alot like flow killing turbulence.

At any rate, I still plan to work this unit over before it goes on. After pricing extrude honing, I'm thinking of going with my other option of having the top of the plenum cut off and hand finishing the runners and runner entries, surfacing the plenum. I may even add a small amount of volume to the plenum when it goes back together. It appears that the piece was designed primarily for street use for stock or slightly larger ports. To support my heads and cam and make my power goal of 460hp at about 6,300, I think it will need to flow a little more, even at the cost of a slight bit of throttle response and low end torque. My 3,500 stall converter and gears will help cover the low end side anyway.

BTW, I'm here to air my ideas as a long time pro mechanic/ hobbiest engine builder. I hope to start a discussion and welcome any and all opinions and feedback on this intake manifold and my ideas for it.

Sorry, tried to attach some photos of the piece for those unfamiliar with it. Seems my photos are too large.

Again, this is the Edelbrock Pro Flow XT EFI tunnel ram P/N 7137.