posted bye

Weav's Vet

HEY GRUMPYVETTE

I took my car to the dyno yesterday. It absolutely sucked! It was down to 277 rwhp from 303 on my last pull before the cam I installed. The torque actually gained a little over my last pull before the cam. up to 310 from 3.07.

To top it off I just made one pull because the car refused to start or do anything after that pull. I'm assuming it was VATS but I don't really know for sure yet. The PCM may have just died on me. I put and extra PCM I had in the car and it fired right up. I got it home and I'm in the process of taking this up with my tuner. He says it probably isn't the tune making it run so bad that it is the motor. I disagree because it ran pretty damn good before the new cam. What do you guys think?

Just to refresh.......1996 LT1

The CPS has been deleted on the car.

The cam is a LE 226/230 .565/.565 111 lsa

The motor is stock and has 95K on it.

The rear gear is 3.07

2800 Pete K stall

EWP

1.6 rr's

Patriot extreme valve springs

New GMPP lifters

Hardened push rods

Guide plates

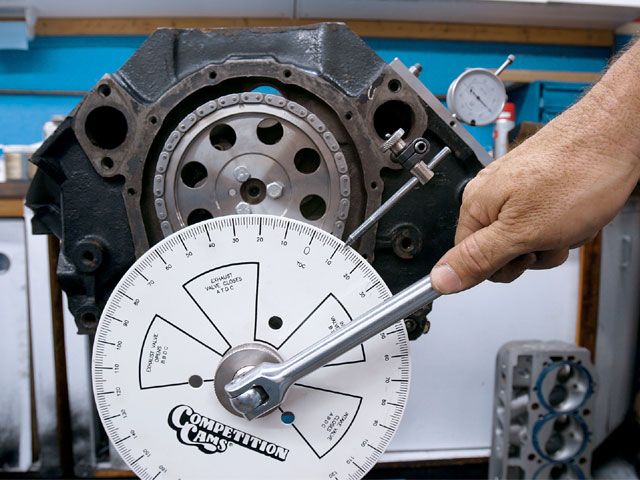

Double roller timing chain

New GM opti

New MSD 8.5 wires

52mm BBK TB

Did a compression test this afternoon just to see what it produced. Good pressure on all. Is this about normal for a 95,000 mile motor?

#1- 210

3- 210

5- 200

7- 200

#2- 220

4- 225

6- 235

8- 225

Weav's Vet

HEY GRUMPYVETTE

I took my car to the dyno yesterday. It absolutely sucked! It was down to 277 rwhp from 303 on my last pull before the cam I installed. The torque actually gained a little over my last pull before the cam. up to 310 from 3.07.

To top it off I just made one pull because the car refused to start or do anything after that pull. I'm assuming it was VATS but I don't really know for sure yet. The PCM may have just died on me. I put and extra PCM I had in the car and it fired right up. I got it home and I'm in the process of taking this up with my tuner. He says it probably isn't the tune making it run so bad that it is the motor. I disagree because it ran pretty damn good before the new cam. What do you guys think?

Just to refresh.......1996 LT1

The CPS has been deleted on the car.

The cam is a LE 226/230 .565/.565 111 lsa

The motor is stock and has 95K on it.

The rear gear is 3.07

2800 Pete K stall

EWP

1.6 rr's

Patriot extreme valve springs

New GMPP lifters

Hardened push rods

Guide plates

Double roller timing chain

New GM opti

New MSD 8.5 wires

52mm BBK TB

Did a compression test this afternoon just to see what it produced. Good pressure on all. Is this about normal for a 95,000 mile motor?

#1- 210

3- 210

5- 200

7- 200

#2- 220

4- 225

6- 235

8- 225