" grumpy? I have a 84 c-10 350/350 , fuel pressure is 5.5psi. I have tried lowering the fuel level in the bowl to the lowest level starting from the "stock" height and I can still not get the fuel to stop percolating. I have installed and reinstalled the thick gasket that goes under the Q jet with no luck. I installed a plastic spacer with no luck, all though it did get a little better. Washing the engine one day , when I turned the engine on the water quickly boiled away under the heat cross over and the reason there is no paint here either . I guess the fix would be to put the blocking plates on the intake gaskets to block off the heat cross over?"

we usually used roofing tin caps,to block off the exhaust cross over passage in the intake manifold to reduce heat,many performance intakes and many performance cylinder heads eliminate that exhaust cross over port, if your gasket set did not have those block-off plates any hardware store sells (tin/caps...brass plated tin sheet steel disks about 1.65" in diam that look like plated thin tin sheet steel that you can use ) use in roof repairs that can easily be modified with tin snips to function correctly for a few cents.

your correct that the exhaust cross over is designed to heat the intake plenum, and blocking it slows the engine warm up time, but unless you live where temps drop below about 40F the difference is seldom critical as all engines tend to build up to operational heat rather quickly (under 5 minutes and in under 2 miles of driving time even at just barely above idle rpm levels.

now If I lived where it snowed I block one side of the exhaust cross over this would reduce the intake plenum heat build up slightly but not a great deal, effectively giving you a bit of a performance boost but not heating the plenum as hot or as quickly

and if hood clearance allowed a 1" phenolic spacer

http://www.summitracing.com/parts/CTR-8 ... refilter=1

function of the egr depends on how the EGR is set up in some cases its a non-issue,as the exhaust gasses are routed to the carb separate from that cross over in some it will simply cease to function with zero effect, most of the time.

if you feel you must maintain EGR but want to reduce carburetor heat levels,

then you simply block only the side of the intake passage away from the EGR on the intake blocking cross flow it will reduce the heat noticeably without causing a problem with the EGR function, with reduced flow and only one end of the cross passage open to only one head, heats significantly reduced

NOTICE STOCK REPLACEMENT INTAKES MAINTAIN THE EGR

NOTICE MOST PERFORMANCE INTAKES ELIMINATE THAT CROSS OVER EXHAUST PASSAGE

Re: vapor lock, cause and cure

if you've got the hood clearance , you can use the well proven trick of installing a heat barrier between the intake and carb bases,

phenolic spacers work well just don,t get the cheap plastic knock off versions that warp and leak, and be aware that the dual plane intakes tend to work best with the 1"and 2" four hole designs but single planes tend to work best with the larger single open plenum designs

if you have the room under the hood a heat barrier and phenolic spacer do a decent job of reducing heat from the engine effecting the fuel in the carb, but I'll point out that the return style fuel pressure regulators keep fresh and cooler fuel at the carb inlet port , thats generally a great help unlike the dead head style of fuel pressure regulators

http://www.summitracing.com/parts/hly-108-70/overview/

http://www.summitracing.com/parts/SUM-G1404/

HEAT BARRIER TYPE SPACER

if your having heat issues like carbs with fuel boiling from engine heat in the intake,a aluminum and gasket heat barrier plus, like the one below with a 1" phenolic spacer placed above it will usually reduce heat transfer rates significantly, as the heats transferred to the engine compartment air before it can get thru the layered barriers

http://www.jegs.com/i/Mr-Gasket/720/371 ... tId=743789

a wood fiber carb spacer can do a great deal of heat insulation between the carb and intake manifold, its better than aluminum or phenolic as a heat barrier, and surprisingly they work great and seldom cause problems when correctly installed

Ive measured a reduction of carb temps of over 50 degrees on some cars with an IR heat gun on the fuel bowls

(one more good reason to have a decent IR temp gun in your tool kit)

viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

http://www.summitracing.com/parts/EDL-8720/?rtype=10

http://www.summitracing.com/parts/EDL-8725/?rtype=10

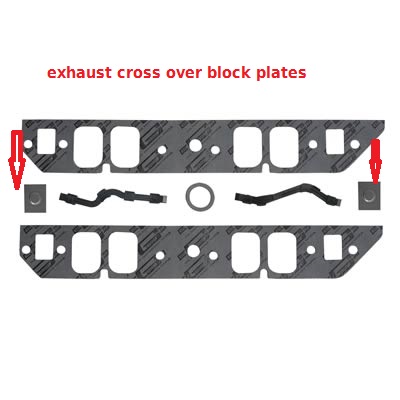

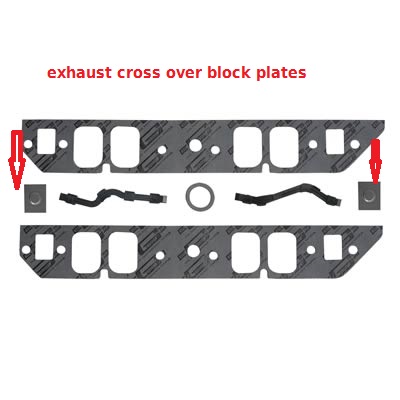

you can also use intake gaskets with small metal plates blocking the exhaust cross over passages that usually further reduces the intake manifold temps.(notice the two small blocking plates at the top of the picture)

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

or at the ends in this picture below

most large hardware or home improvement stores sell (tin/caps...brass plated tin sheet steel disks

about 1.65" in diam that look like plated thin tin sheet steel that you can use ) yes they can occasionally burn through over thousands of miles of use but they cost next to nothing but a few cents to replace if that happens, the discs are use in roof repairs that can easily be modified with tin snips to function correctly for a few cents

most bbc intake gasket sets come with exhaust block plate inserts

Id get a IR temp gun and verify the engines operating temps but remember to verify the coolant and oil capacity are correct.

infrared thermometers are a very useful tool to track down issues with tuning, or mal functioning sensors , without verified facts your guessing.

this is the most consistently accurate I.R temp gun I've used for testing

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

BTW, if you want too theres a few extra hp, available if you use an air-gap style intake manifold ,

without any problems, you can just block both sides of the exhaust cross over passage,

in the intake manifolds that have one even with a lifter gallery oil shield in place,

the engine heat will be more than adequate too vaporize fuel droplets in the plenum,

once the oil and coolant temp reaches operational temps.

naturally outside air and engine compartment air temperatures will effect the manifold plenum temp and blocking off the manifold exhaust gas cross over will tend to slow the rate of heat build-up and peak heat reached ,some what but if you check with the infrared temp gun you might be amazed to find the temperature difference of the plenum after either intake design reaches operational temps is rarely lower than about 170f f-180f on the air-gap style even with rather cool outside air temps and thats certainly sufficient heat to vaporize plenum fuel droplets.

we usually used roofing tin caps,to block off the exhaust cross over passage in the intake manifold to reduce heat,many performance intakes and many performance cylinder heads eliminate that exhaust cross over port, if your gasket set did not have those block-off plates any hardware store sells (tin/caps...brass plated tin sheet steel disks about 1.65" in diam that look like plated thin tin sheet steel that you can use ) use in roof repairs that can easily be modified with tin snips to function correctly for a few cents.

your correct that the exhaust cross over is designed to heat the intake plenum, and blocking it slows the engine warm up time, but unless you live where temps drop below about 40F the difference is seldom critical as all engines tend to build up to operational heat rather quickly (under 5 minutes and in under 2 miles of driving time even at just barely above idle rpm levels.

now If I lived where it snowed I block one side of the exhaust cross over this would reduce the intake plenum heat build up slightly but not a great deal, effectively giving you a bit of a performance boost but not heating the plenum as hot or as quickly

and if hood clearance allowed a 1" phenolic spacer

http://www.summitracing.com/parts/CTR-8 ... refilter=1

function of the egr depends on how the EGR is set up in some cases its a non-issue,as the exhaust gasses are routed to the carb separate from that cross over in some it will simply cease to function with zero effect, most of the time.

if you feel you must maintain EGR but want to reduce carburetor heat levels,

then you simply block only the side of the intake passage away from the EGR on the intake blocking cross flow it will reduce the heat noticeably without causing a problem with the EGR function, with reduced flow and only one end of the cross passage open to only one head, heats significantly reduced

NOTICE STOCK REPLACEMENT INTAKES MAINTAIN THE EGR

NOTICE MOST PERFORMANCE INTAKES ELIMINATE THAT CROSS OVER EXHAUST PASSAGE

Re: vapor lock, cause and cure

if you've got the hood clearance , you can use the well proven trick of installing a heat barrier between the intake and carb bases,

phenolic spacers work well just don,t get the cheap plastic knock off versions that warp and leak, and be aware that the dual plane intakes tend to work best with the 1"and 2" four hole designs but single planes tend to work best with the larger single open plenum designs

if you have the room under the hood a heat barrier and phenolic spacer do a decent job of reducing heat from the engine effecting the fuel in the carb, but I'll point out that the return style fuel pressure regulators keep fresh and cooler fuel at the carb inlet port , thats generally a great help unlike the dead head style of fuel pressure regulators

http://www.summitracing.com/parts/hly-108-70/overview/

http://www.summitracing.com/parts/SUM-G1404/

HEAT BARRIER TYPE SPACER

if your having heat issues like carbs with fuel boiling from engine heat in the intake,a aluminum and gasket heat barrier plus, like the one below with a 1" phenolic spacer placed above it will usually reduce heat transfer rates significantly, as the heats transferred to the engine compartment air before it can get thru the layered barriers

http://www.jegs.com/i/Mr-Gasket/720/371 ... tId=743789

a wood fiber carb spacer can do a great deal of heat insulation between the carb and intake manifold, its better than aluminum or phenolic as a heat barrier, and surprisingly they work great and seldom cause problems when correctly installed

Ive measured a reduction of carb temps of over 50 degrees on some cars with an IR heat gun on the fuel bowls

(one more good reason to have a decent IR temp gun in your tool kit)

viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

http://www.summitracing.com/parts/EDL-8720/?rtype=10

http://www.summitracing.com/parts/EDL-8725/?rtype=10

you can also use intake gaskets with small metal plates blocking the exhaust cross over passages that usually further reduces the intake manifold temps.(notice the two small blocking plates at the top of the picture)

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

or at the ends in this picture below

most large hardware or home improvement stores sell (tin/caps...brass plated tin sheet steel disks

about 1.65" in diam that look like plated thin tin sheet steel that you can use ) yes they can occasionally burn through over thousands of miles of use but they cost next to nothing but a few cents to replace if that happens, the discs are use in roof repairs that can easily be modified with tin snips to function correctly for a few cents

most bbc intake gasket sets come with exhaust block plate inserts

Id get a IR temp gun and verify the engines operating temps but remember to verify the coolant and oil capacity are correct.

infrared thermometers are a very useful tool to track down issues with tuning, or mal functioning sensors , without verified facts your guessing.

this is the most consistently accurate I.R temp gun I've used for testing

http://www.testequipmentdepot.com/e...1100200223789&utm_content=All Extech Products

INFRARED TEMP GUN

BTW, if you want too theres a few extra hp, available if you use an air-gap style intake manifold ,

without any problems, you can just block both sides of the exhaust cross over passage,

in the intake manifolds that have one even with a lifter gallery oil shield in place,

the engine heat will be more than adequate too vaporize fuel droplets in the plenum,

once the oil and coolant temp reaches operational temps.

naturally outside air and engine compartment air temperatures will effect the manifold plenum temp and blocking off the manifold exhaust gas cross over will tend to slow the rate of heat build-up and peak heat reached ,some what but if you check with the infrared temp gun you might be amazed to find the temperature difference of the plenum after either intake design reaches operational temps is rarely lower than about 170f f-180f on the air-gap style even with rather cool outside air temps and thats certainly sufficient heat to vaporize plenum fuel droplets.

Last edited by a moderator: