the stock flex-plate is a 153 tooth internally balanced design, the 168 tooth flex plate WILL clear the stock bell housing and work but you'll need a different starter and in most cases headers and other clearance issues will restrict your choices to the high torque mini starters, most 400 sbc require a externally balanced flex plate and matching externally balance damper or balancer, in many cases it a larger diam,. and that can cause clearance issues with the front K-frame in some cases

viewtopic.php?f=70&t=458&p=2911&hilit=+mini+starter#p2911

viewtopic.php?f=70&t=458&p=1545&hilit=starters#p1545

http://www.atiracing.com/products/flexp ... xplate.htm

http://www.carcraft.com/techarticles/cc ... ewall.html

http://www.gmpartsdirect.com/performanc ... D=913.html

keep in mind theres 3 and 6 bolt torque converters and several bolt pattern diameters

the spline counts and shaft diameters differ in various applications so do the required research

EXAMPLE

10.750 in.

11.500 in.

OEM flex plates are far thinner and more flexible than the SFI certified flex-plates , so they are far more likely to crack and split over time

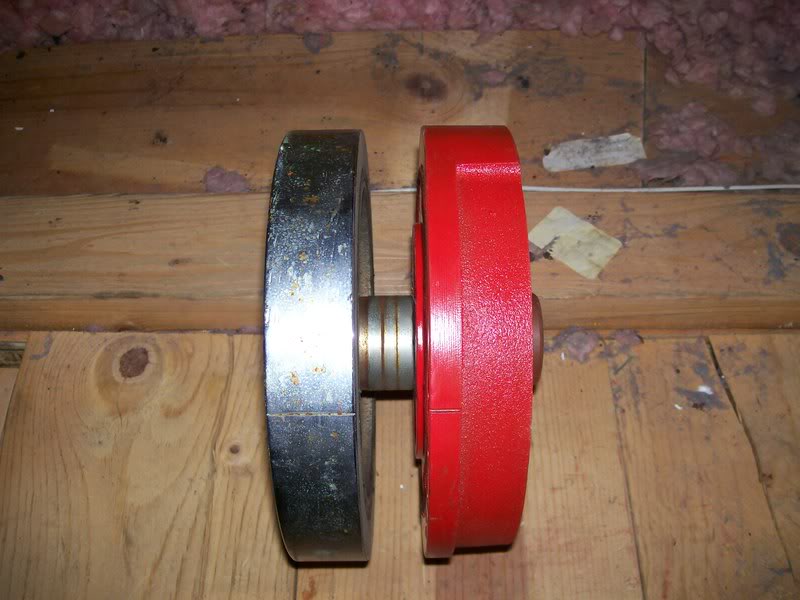

.the raised side of the indentations go TOWARD the converter , in the picture above the crank flange mating side faces away from you

Instructions

1

Determine which side of the flexplate goes against the crankshaft. Looking at the center of the flexplate, where the bolts go, one side is recessed. This side faces away from the crankshaft.

2

Clean the mounting flange on the crankshaft and the mounting area of the flexplate with parts cleaner and a shop rag.

Sponsored Links

Fiber Glass Developments

Find Quality Composite Materials. Shop Fibre Glast Products Today!

http://www.fibreglast.com

3

Mount the flexplate on the crankshaft with the recessed part facing away from the crankshaft. Line up the mounting holes. You will be able to see that the flexplate is flush against the crankshaft by looking at the mounting holes.

4

Install the bolts by hand until finger tight. You must use the special flexplate bolts. These bolts have a special shoulder and a thin head. If you try to use regular bolts, the torque converter will not fit properly; the flexplate will not be held against the crankshaft properly. Damage will ensue.

5

Stick a large flat-head screwdriver through one of the slots toward the outside of the flexplate. The end of the screwdriver should rest against the engine block. This position will keep it from moving when you torque the bolts.

6

Use a torque wrench and socket to torque the bolts to the factory specification for your specific engine and transmission. Torque the bolts in a crisscross pattern, similar to how you would tighten lug nuts.