You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

rather interesting info on a big block turbo build

- Thread starter grumpyvette

- Start date

8

87vette81big

Guest

What do they mean by the test BBC having Cast Rods Grumpy?

I wasn't aware if any having cast rods ever.

Just the ZZ Sbc over the counter engines and base LS engines.

And Pontiac late 1963- 1979 Cast Arma Steel Rods used in Non Ram Air 5 & SD455 & SD421.

I wasn't aware if any having cast rods ever.

Just the ZZ Sbc over the counter engines and base LS engines.

And Pontiac late 1963- 1979 Cast Arma Steel Rods used in Non Ram Air 5 & SD455 & SD421.

8

87vette81big

Guest

Seems to me the HP Limits of stock parts can pushed to high limits Turbocharged as long as Detonation is avoided.

Just not well documented what those limits are.

Just not well documented what those limits are.

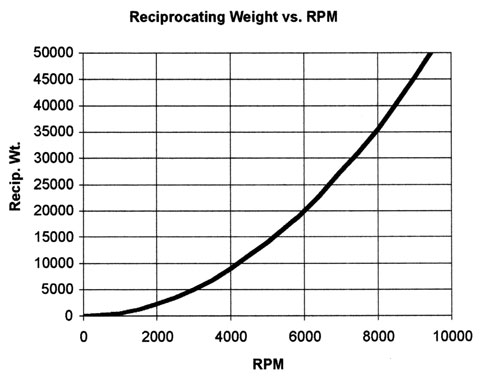

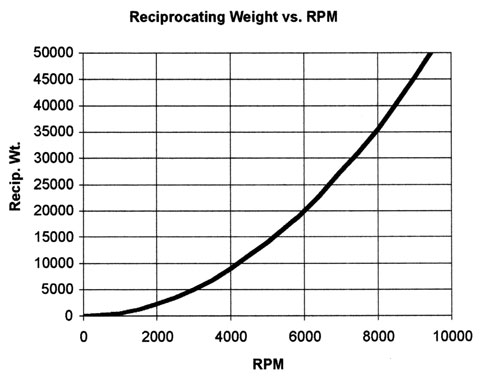

detonation and lean fuel ratios normally are related to piston and ring failures which are related too heat damage related failures or lack of maintaining proper lubrication and adequate component cooling, rods don,t generally fail in compression, on the power stroke where the full cross sectional area of the connecting rod bears the forces, the heavy connecting rod and piston assembly, generally cause rod bolts to fail, by stretching on the exhaust stroke where the rod bolts try to keep the heavy connecting rod and piston assembly from stretching the two rod bolts and the resulting loss of bearing contact area and adequate lubrication, rapidly followed by rod bearing failure which rapidly results in the connecting rod hammering the crank journal, until the connecting rod breaks loose , remember the piston and rod assembly plays CRACK THE WHIP, against near ZERO resistance on the exhaust stroke, but on the compression stroke theres nearly 15-16 square inches of piston surface compressing the gases above the piston,to several hundred PSI even before ignition takes place, that keep the connecting rod, seated on the crank journal and bearings.

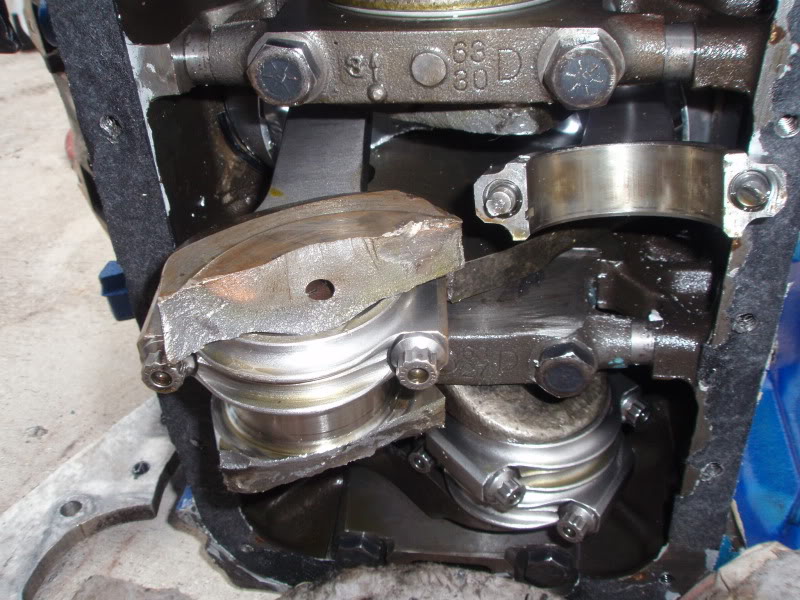

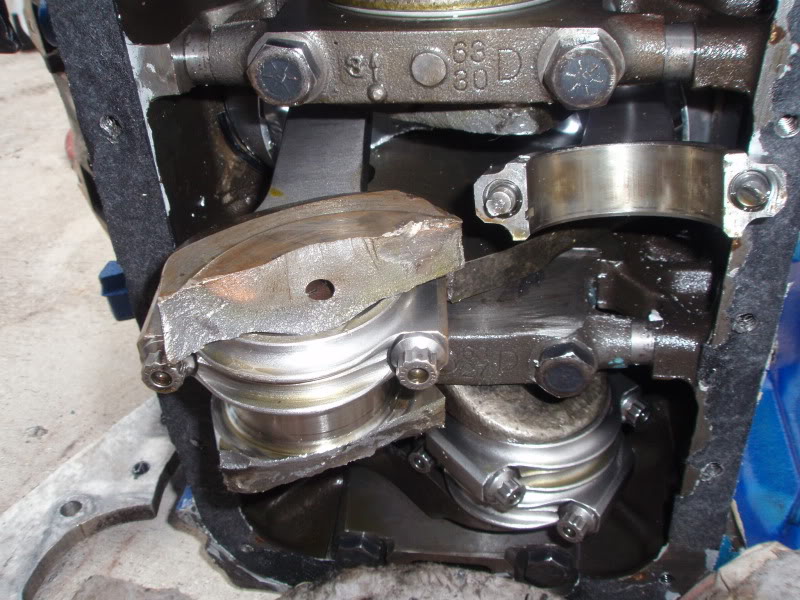

this is one of the few stock big block rods Ill recondition and have used successfully

RELATED INFO

viewtopic.php?f=50&t=208&p=487&hilit=compression+test#p487

viewtopic.php?f=53&t=510

viewtopic.php?f=53&t=341

viewtopic.php?f=53&t=204&hilit=connecting+rod+bolts

viewtopic.php?f=53&t=1168

this is one of the few stock big block rods Ill recondition and have used successfully

RELATED INFO

viewtopic.php?f=50&t=208&p=487&hilit=compression+test#p487

viewtopic.php?f=53&t=510

viewtopic.php?f=53&t=341

viewtopic.php?f=53&t=204&hilit=connecting+rod+bolts

viewtopic.php?f=53&t=1168

8

87vette81big

Guest

I clicked on all your links Grumpy.

I have read prior. Really.

Either the Magazine tests are truth.

Or a lie.

No way of knowing from the article.

I have read prior. Really.

Either the Magazine tests are truth.

Or a lie.

No way of knowing from the article.

8

87vette81big

Guest

Without knowing actual Balance Bob Weights as shown on A Stewart Warner Balance Card, nothing meaninfull can be calculated .

Worthless bench racing to me Grumpy.

Worthless bench racing to me Grumpy.

the fact that they state that they get the engine too survive a few pulls at the 1200 horse power level on boost with a turbo,does not in my mind prove it will last for several hundred repeats under that stress level. and that they got that out of a supposedly stock CAST crank' amazed me, but like I stated, several times in various threads, its stress induced by higher rpms and valve train control failures , detonation and leaning out during a pull that tends to destroy rods and bearings,and STRESS IS CUMULATIVE! like bending a paper clip back and forth in a 90 degree angle, it seldom breaks during the first dozen cycles, but it won,t go one hundred in rapid succession, without failing either.

you can get away with some amazing things a few times, but stress is cumulative!

you can do many things for a limited time and get away with them without having a component fail, that's not an indication that no structural damage was being or has been done!,its like bending a paper clip back and forth, repeatedly, it rarely fails in the first dozen bend cycles but it also rarely last 3-4 dozen cycles before failing.

Id bet those main caps were walking in the saddles , and beating the bearing surfaces up rather badly and that cast crank was flexing like the paper clip analogy

its been my experience that the stock,high performance chevy connecting rods and a 4 bolt block with ARP STUDS added, and used with a 5140 forged steel crank and carefully reworked L88 and LS7 and SOME of the TRUCK rods with 7/16" ARP wave rod bolts will handle a surprising amount of power , easily handling 7000rpm-7500rpm at least occasionally in a 3.76" stroke 427 engine.

Ive built several 454-468 big blocks with 4" stroke cranks and STOCK cast cranks with those rods that made in excess of 600 hp but at a lower 6500rpm max. I see far more failures traced to detonation or loss of valve train control than lower end rotating assembly failures.

you can,t compress a busted valve, the stock blocks with 4 bolt mains are surprisingly durable provided the blocks not bored more than about .060 over size , but the stock block are no ware near as strong or stiff as the DART BLOCKS and if your going to put thousands of dollars of rotating assembly and machine work into a short block you damn sure don,t want something coming apart at 6000rpm plus.

Ive built lots of 396-302 and 454 2 bolt blocks that made 500hp-550hp but I generally throw the 3/8" rod bolt rods in the trash, simply because the cost of 150%-200% stronger after market connecting rods cost considerably LESS than the cost of PROPERLY upgrading the stock rods, adding ARP rod bolts and polishing the surface and having them balanced, mag checked for flaws and all the other stuff that the aftermarket performance rods already have done out of the box.

GUYS look at the END RESULT AND BLAME A BENT CONNECTING ROD THAT BEAT ITS WAY THRU THE OIL PAN AS THE CAUSE OF AN ENGINE FAILURE, when the truth is you can,t expect a connecting rod to compress a bent valve or not come loose and bend if a rod bolt stretches and the bearings spin, the failure of the connecting rod in those cases was the RESULT not the CAUSE

GET THE CLEARANCES WRONG OR OVER REV THE ENGINE AND BAD /EXPENSIVE THINGS CAN OCCUR,AS CAN BE THE RESULT OF GETTING LAZY AND ASSUMING THE CLEARANCES ARE CORRECT IF YOU DON,T CHECK

why cast cranks and high stress and rpm are a bad idea

viewtopic.php?f=53&t=204&hilit=connecting+rod+bolts

you can get away with some amazing things a few times, but stress is cumulative!

you can do many things for a limited time and get away with them without having a component fail, that's not an indication that no structural damage was being or has been done!,its like bending a paper clip back and forth, repeatedly, it rarely fails in the first dozen bend cycles but it also rarely last 3-4 dozen cycles before failing.

Id bet those main caps were walking in the saddles , and beating the bearing surfaces up rather badly and that cast crank was flexing like the paper clip analogy

its been my experience that the stock,high performance chevy connecting rods and a 4 bolt block with ARP STUDS added, and used with a 5140 forged steel crank and carefully reworked L88 and LS7 and SOME of the TRUCK rods with 7/16" ARP wave rod bolts will handle a surprising amount of power , easily handling 7000rpm-7500rpm at least occasionally in a 3.76" stroke 427 engine.

Ive built several 454-468 big blocks with 4" stroke cranks and STOCK cast cranks with those rods that made in excess of 600 hp but at a lower 6500rpm max. I see far more failures traced to detonation or loss of valve train control than lower end rotating assembly failures.

you can,t compress a busted valve, the stock blocks with 4 bolt mains are surprisingly durable provided the blocks not bored more than about .060 over size , but the stock block are no ware near as strong or stiff as the DART BLOCKS and if your going to put thousands of dollars of rotating assembly and machine work into a short block you damn sure don,t want something coming apart at 6000rpm plus.

Ive built lots of 396-302 and 454 2 bolt blocks that made 500hp-550hp but I generally throw the 3/8" rod bolt rods in the trash, simply because the cost of 150%-200% stronger after market connecting rods cost considerably LESS than the cost of PROPERLY upgrading the stock rods, adding ARP rod bolts and polishing the surface and having them balanced, mag checked for flaws and all the other stuff that the aftermarket performance rods already have done out of the box.

GUYS look at the END RESULT AND BLAME A BENT CONNECTING ROD THAT BEAT ITS WAY THRU THE OIL PAN AS THE CAUSE OF AN ENGINE FAILURE, when the truth is you can,t expect a connecting rod to compress a bent valve or not come loose and bend if a rod bolt stretches and the bearings spin, the failure of the connecting rod in those cases was the RESULT not the CAUSE

GET THE CLEARANCES WRONG OR OVER REV THE ENGINE AND BAD /EXPENSIVE THINGS CAN OCCUR,AS CAN BE THE RESULT OF GETTING LAZY AND ASSUMING THE CLEARANCES ARE CORRECT IF YOU DON,T CHECK

why cast cranks and high stress and rpm are a bad idea

viewtopic.php?f=53&t=204&hilit=connecting+rod+bolts

Physics Forums said:Over revving is the main cause of connecting rod failures in new and high performance engines. If the tachometer hits the red--even briefly--the connection rods are in danger of breaking. This is because the forces acting on a connecting rod increase dramatically at high revolutions. It does not matter if the tachometer is going into the red because the race car is traveling at a high speed, is going too fast in a low gear or is simply going too fast because the accelerator is pressed too far while the car is in neutral--the stress is simply too high at extremely high RPMs. One thing that may happen when you over rev is valve float to the point the head of the valve gets smacked and bent and breaks off, gets eaten by the piston and there goes the top of the piston. Then you have rod slapping around the bore. Not good. Generally the rod will be in one mangled piece more or less.

Hydrolock is a deformation of the connecting rod caused when water gets into the piston chamber. This usually happens when the head gasket blows and water enters the combustion chamber. Even a momentary hydro lock will bend the rod and cause it's failure.

One sure way to ruin an engine is DETONATION which would distort the rod bearing and cause it to spin and seize the Big end . Detonation will cause piston damage, bent rods, broken blocks, and bearing failure. I have never seen a case of detonation where there was not evidence in the combustion chamber.

House keeping or lack of proper maintenance will ruin an engine as the table below ( from Clevite Bearings) shows. You plug or restrict oil and the bearing fails . This usually results in a lot of noise but no catastrophic damage..usually..

Lets look at the rod bearing and Major causes of premature Bearing failure

Dirt..........................................45.4%

Misassembly...........................12.8%

Misalignment ..........................12.6%

Insufficient Lubrication.............11.4%

Overloading ..............................8.1%

Corrosion..................................3.7%

Improper Journal Finish............3.2%Other ........................................2.8%

8

87vette81big

Guest

Yes Grumpy.

There hasn't been any good articles in a long time on design criteria for several popular engines.

My point.

I know you know BBC best.

SBC too.

Pontiac best represented by early work of HO Racing.

Thier books HO1 & HO2 are hard to find today.

Been out of print for 20+ years.

I have them still.

Takes to an engineering and practicle level.

I haven't found them online ever. Just bits & pieces scanned in during forum posts by others.

Today its just buy this to do that.

No background why or if its good or not.

Or could be better.

All fundamentals left out. Forget about Math too.

Just don't show it.

So you wonder....??

There hasn't been any good articles in a long time on design criteria for several popular engines.

My point.

I know you know BBC best.

SBC too.

Pontiac best represented by early work of HO Racing.

Thier books HO1 & HO2 are hard to find today.

Been out of print for 20+ years.

I have them still.

Takes to an engineering and practicle level.

I haven't found them online ever. Just bits & pieces scanned in during forum posts by others.

Today its just buy this to do that.

No background why or if its good or not.

Or could be better.

All fundamentals left out. Forget about Math too.

Just don't show it.

So you wonder....??

8

87vette81big

Guest

I know Turbocharging & Supercharging is real hard on exhaust valves and seats.

Its never discussed in magazine articles too.

So ???? !

Its never discussed in magazine articles too.

So ???? !

philly

solid fixture here in the forum

theres gotta be something there.... some details arent revealed to us, because 28psi on race gas should net you more like 1500hp with that displacement.

and i am completely in agreement that just because it made the number one with 60 DEGREE IAT'S doesnt mean its gonna survive in a vehicle.

however the article was entertaining and i would totally believe that you can make 750-900 streetable horsepower with that combo and survive for a long time if the tune was right.

and i am completely in agreement that just because it made the number one with 60 DEGREE IAT'S doesnt mean its gonna survive in a vehicle.

however the article was entertaining and i would totally believe that you can make 750-900 streetable horsepower with that combo and survive for a long time if the tune was right.

8

87vette81big

Guest

Something is just Fucked up with article Phil.philly said:theres gotta be something there.... some details arent revealed to us, because 28psi on race gas should net you more like 1500hp with that displacement.

and i am completely in agreement that just because it made the number one with 60 DEGREE IAT'S doesnt mean its gonna survive in a vehicle.

however the article was entertaining and i would totally believe that you can make 750-900 streetable horsepower with that combo and survive for a long time if the tune was right.

CAST RODS IN A BBC.

BULLSHIT.

ALL DROP FORGED STEEL STOCK.

2 GUYS HOLDING THE ENGINEERING MINI SLEDGES HAVE BEEN WRITING HOTROD & CARCRAFT TECH FOR OVER 20 YEARS.

8

87vette81big

Guest

Pontiac 455 Cranks are Super Strong Grumpy.

Strongest stock ever.

Strongest stock ever.

philly

solid fixture here in the forum

maybe i dont know enough about it, but it seems to me that the majority of the real damage to cranks comes from them either walking out of balance, an oiling issue, or some other mechanical catastrophe that would have rendered a forged crank useless also. i know my buddy raced with a loose balancer and didnt notice until the motor locked up, pulled the main caps off and the crank sprung out into a slight banana shape... go figure.