If you strip a carb mount stud the correct route to repair it is to have it tig welded and re-tapped, every shop needs a decent drill press and a set of taps, for doing those simple repairs, having a tig or mig welder set up for both steel and aluminum is a huge plus

BTW everyone eventually screws up some part made of aluminum, and TIG welding and re machining will fix almost any aluminum part, especially cylinder heads where heat and pressure make using epoxy less than ideal in many cases, but for minor intake manifold runner, and plenum repairs you usually have a second option, with welding you take a chance of warping the intake casting, but with a paste made from two part epoxy, 75% epoxy and 25% aluminum powder mix, the mix makes a very durable port wall filler paste,vaguely resembling a silver bondo paste but far more durable..

this paste is very useful when correcting intake runner porting mistakes as the paste once cured is machinable to some extent almost like the original aluminum, just be very sure the surface you use the epoxy on is very clean and a thin wet bond coat of epoxy gel a few thousands thick used just before using the paste on the surface before applying the aluminum mixed epoxy filler helps bond the mixed paste

http://www.ramracing.us/products.htm

http://www.jamestowndistributors.com/us ... 8&type=pla

OR

http://www.aluminumrepair.com/faqs.asp

http://www.aluminumrepair.com/technical.asp

http://durafix.com/demo/256.html

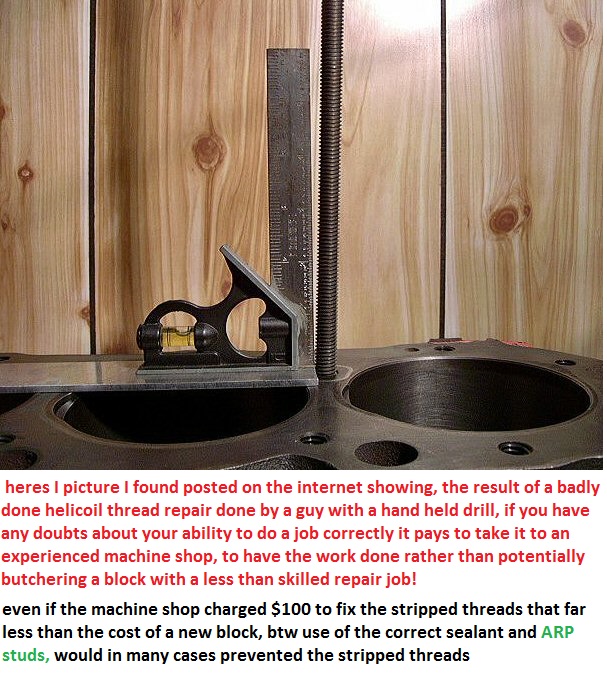

if its only partly stripped a helicoil might work,

http://www.emhart.com/pdf/Heli%20Coil/H ... ev%204.pdf

http://www.roadstarmagazine.com/modules ... le&sid=233

these may help

http://www.mcmaster.com/#thread-repair-kits/=7oobjd

viewtopic.php?f=60&t=1562

http://www.ehow.com/how_5121714_remove- ... bolts.html

keep in mind that a stud threaded into aluminum must have its threads engage to a depth of 2.5 times its diameter to have its maximum hold power in most aluminum and its a good idea to use red loc-tite on the threads, to prevent the stud easily backing out during the assembly process, bolts wear the threads faster

BTW everyone eventually screws up some part made of aluminum, and TIG welding and re machining will fix almost any aluminum part, especially cylinder heads where heat and pressure make using epoxy less than ideal in many cases, but for minor intake manifold runner, and plenum repairs you usually have a second option, with welding you take a chance of warping the intake casting, but with a paste made from two part epoxy, 75% epoxy and 25% aluminum powder mix, the mix makes a very durable port wall filler paste,vaguely resembling a silver bondo paste but far more durable..

this paste is very useful when correcting intake runner porting mistakes as the paste once cured is machinable to some extent almost like the original aluminum, just be very sure the surface you use the epoxy on is very clean and a thin wet bond coat of epoxy gel a few thousands thick used just before using the paste on the surface before applying the aluminum mixed epoxy filler helps bond the mixed paste

http://www.ramracing.us/products.htm

http://www.jamestowndistributors.com/us ... 8&type=pla

OR

http://www.aluminumrepair.com/faqs.asp

http://www.aluminumrepair.com/technical.asp

http://durafix.com/demo/256.html

if its only partly stripped a helicoil might work,

http://www.emhart.com/pdf/Heli%20Coil/H ... ev%204.pdf

http://www.roadstarmagazine.com/modules ... le&sid=233

these may help

http://www.mcmaster.com/#thread-repair-kits/=7oobjd

viewtopic.php?f=60&t=1562

http://www.ehow.com/how_5121714_remove- ... bolts.html

keep in mind that a stud threaded into aluminum must have its threads engage to a depth of 2.5 times its diameter to have its maximum hold power in most aluminum and its a good idea to use red loc-tite on the threads, to prevent the stud easily backing out during the assembly process, bolts wear the threads faster

Last edited by a moderator: