HERES THAT POST GTR1999 POSTED

This is a 1971 LT1 Diff a local guy brought in to me to check for him last winter.

This car was just purchased and he was told no one worked on the diff to their knowledge. I checked the side yoke play. .020-.025" was found but the play was in the sloppy stock posi not yoke wear. This will be discussed in another post or two so you'll just have to wait!:smack What I did was to mount the diff on my engine stand and put some gear oil it. After 5-6 hours I noticed a leak at the pinion seal and proceeded to replace it.

Here is the diff sitting on the stand with oil in it. I do this with every rebuild as well just to be sure. I let them sit 24-48 hours sometimes more.

Here is the close up.

Before tearing it apart you want to know where the reference points are. If doing this in the car you need to mark the pinion yoke,nut, and pinion end so that they all go back together in the same relationship to maintain the bearing preload. Since I have it out it is much easier to get a precise reading of drag with my 0-30 in/lb dial wrench. Used bearings should spin smooth and have about 5 in/lbs of drag.

I found someone was into this before. The witness marks were there and I heard the replacement seal hitting the yoke shield when I turned it by hand.

I use a puller to remove the yoke, this is one my friend Tom Buddy clued me in on years ago. Works great on these and rebuilding a diff when you have to pull the pinion off a lot during setup.

You want to look over the parts when you remove them. Here is the seal the previous mechanic installed.You have to look at the gap between the flange and housing. Usually it's about .125" but that can vary. Hitting it home will distort it and leaving too high the yoke will hit the flange as on this one.

You can see where the seal flange hit the yoke.

Also the last guy was clueless installing the seal. Here are the pinion yoke splines- no sealer. Oil will wick up and out if installed like this.

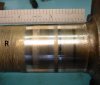

Here is the yoke. Look at the OD where it mates with the seal. If there is wear there you need to buy those expensive speedy sleeves or you'll have a leak.

Unlike some places my goal is not to sell parts or services. Instead of telling the guy the yoke was NG I cleaned it up and checked it on our scope. This one didn't need the sleeve.

Here's the new CR seal. Spend the extra couple of bucks and buy the best parts. Not all seals are the same and I have seen some rebuild kits on the market with the cheapest junk you can find. This is a CR/SKF seal.

Here is the secret to stopping a future leak- good old #2 on the splines. A few bucks for the right stuff saves you a lot of swearing in a few weeks!:spanked:

Back together, torqued and ready for the leak test.

24 hours later dry as the moment I installed it.

I reused the yokes with 90k miles on them, replaced the seal, installed Lucas 85-140 gear oil and GM additive, Back to the owner.

This is the type of post I usually do. What is your feedback?

Gary