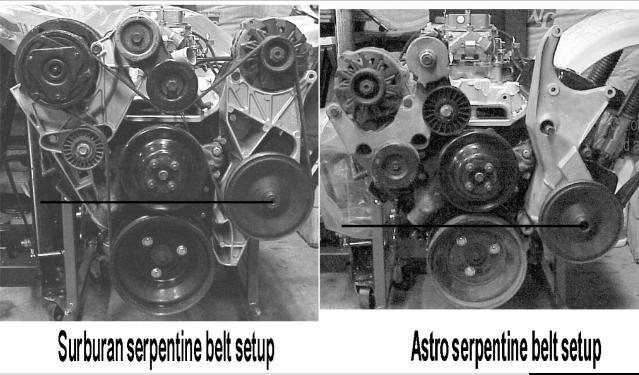

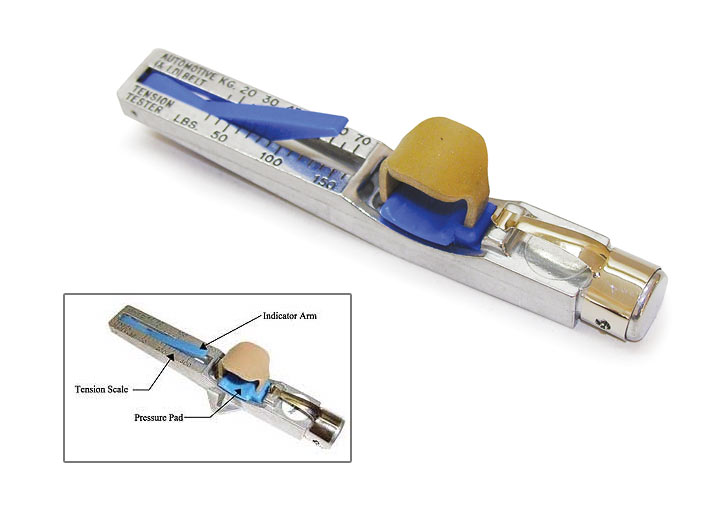

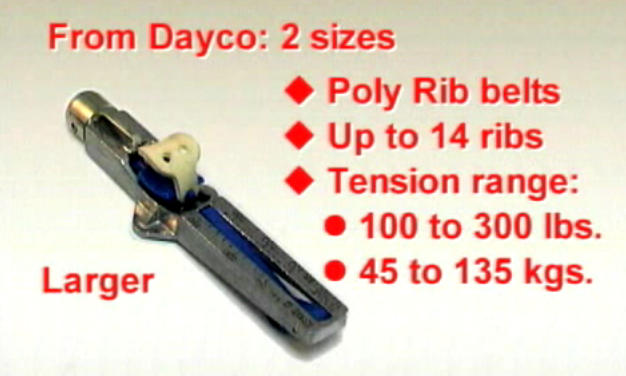

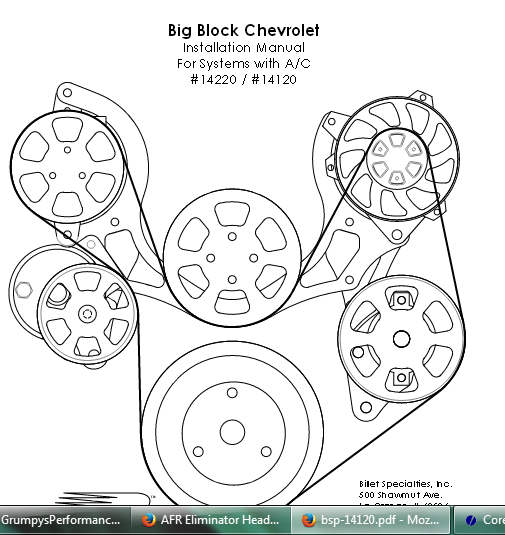

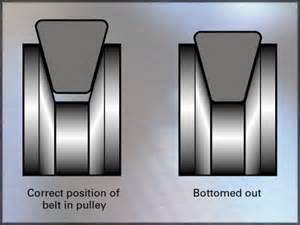

If the belts correctly installed and correctly adjusted ,it should be reasonably difficult to exceed 1/2" deflection over the fan belts unsupported length,PROVIDED the belt tensioned pulley is adjusted correctly (usually the alternator, on v-belts) and if you've got a belt tensioned (serpentine belts)is working correctly, but some FAN BELT DRESSING should add a bit of traction surface and cure the problem, its sprayed onto the belt at idle speeds so it covers both the belt and pulley surfaces,

so be careful not to get grabbed by the fan belt of get belt dressing thrown onto your shirt,etc. and NEVER EVER WEAR LOOSE CLOTHES OR A TIE while adjusting ANYTHING ON a running engine

if you find belts squeal or your wearing belts or belts are coming off at higher rpms ,STOP and look very closely!

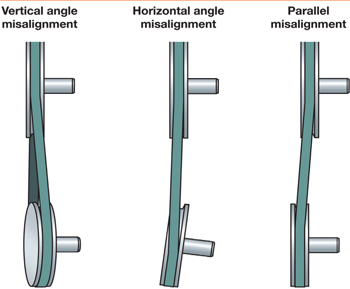

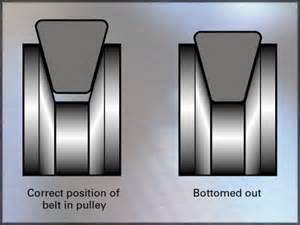

and do a very close inspection,of all the accessorizes, try wiggling accessories once the belts removed and check pulley groove alignment very carefully, with a strait edge yard stick, because at times a squealing belt indicates come component or accessory drive is coming loose, damper bolts or accessories pulleys do get loose

http://www.waybuilder.net/sweethaven/Me ... &modNum=12

http://autorepair.about.com/od/quicktip ... essing.htm

http://automotivemileposts.com/autobrev ... ecoil.html

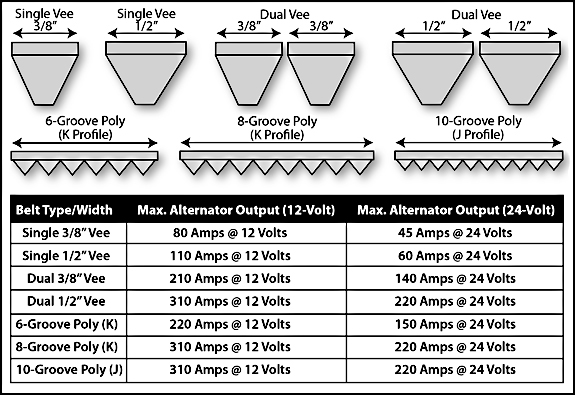

swapping to a tooth belt is an option

http://www.stefs.com/products/gilmerbeltcharts.htm

these guys sell cog belt drives

http://www.millerspeed.com/

if the radiator or heater hose swells noticeably and feels spongy , or if the hose has obvious surface flaking or cracks the hose is deteriorated internally to the point mandatory replacement is required or your looking at it failing withing a few months, or just weeks time in most cases.

if a serpentine belt starts to show cracks in its ribs, or frayed edges, you also check the pulley alignment and condition of the pulley surfaces, as rust or mis-alignment will cause wear issues.

heat and age and in a few cases use of the wrong coolant , or exhaust leaks in head gaskets or getting misted with petroleum products from an oil, power steering or transmission fluid leak will deteriorate the hose , or belt rubber.

if its the result of oil age and heat you replace it and if its the result of a fluid leak you cure the leak source first and replace it and, you can assume all belts and hoses need to be replaced by the time they are about 5-6 years old or by about 60k- miles which ever comes first, as a normal maintenance replacement item if your not looking to get stranded

yes IM fully aware theres thousands of cars running original belts and hoses at 140k miles, many are pushing their luck, if not carefully inspected frequently.

http://www.aa1car.com/library/belthose.htm

hose clamps also tend to rust or loose tension over time causing them to fail so use of new clamps when installing a hose is good maintenance, procedure

so be careful not to get grabbed by the fan belt of get belt dressing thrown onto your shirt,etc. and NEVER EVER WEAR LOOSE CLOTHES OR A TIE while adjusting ANYTHING ON a running engine

if you find belts squeal or your wearing belts or belts are coming off at higher rpms ,STOP and look very closely!

and do a very close inspection,of all the accessorizes, try wiggling accessories once the belts removed and check pulley groove alignment very carefully, with a strait edge yard stick, because at times a squealing belt indicates come component or accessory drive is coming loose, damper bolts or accessories pulleys do get loose

http://www.waybuilder.net/sweethaven/Me ... &modNum=12

http://autorepair.about.com/od/quicktip ... essing.htm

http://automotivemileposts.com/autobrev ... ecoil.html

swapping to a tooth belt is an option

http://www.stefs.com/products/gilmerbeltcharts.htm

these guys sell cog belt drives

http://www.millerspeed.com/

if the radiator or heater hose swells noticeably and feels spongy , or if the hose has obvious surface flaking or cracks the hose is deteriorated internally to the point mandatory replacement is required or your looking at it failing withing a few months, or just weeks time in most cases.

if a serpentine belt starts to show cracks in its ribs, or frayed edges, you also check the pulley alignment and condition of the pulley surfaces, as rust or mis-alignment will cause wear issues.

heat and age and in a few cases use of the wrong coolant , or exhaust leaks in head gaskets or getting misted with petroleum products from an oil, power steering or transmission fluid leak will deteriorate the hose , or belt rubber.

if its the result of oil age and heat you replace it and if its the result of a fluid leak you cure the leak source first and replace it and, you can assume all belts and hoses need to be replaced by the time they are about 5-6 years old or by about 60k- miles which ever comes first, as a normal maintenance replacement item if your not looking to get stranded

yes IM fully aware theres thousands of cars running original belts and hoses at 140k miles, many are pushing their luck, if not carefully inspected frequently.

http://www.aa1car.com/library/belthose.htm

hose clamps also tend to rust or loose tension over time causing them to fail so use of new clamps when installing a hose is good maintenance, procedure