(cam install feed back)

[CARLOS] story:hey grumpy...

I just got my chevy ZZ3 rebuilt.The engine shop did some porting work to the ZZ3 heads and added domed TRW pistons (CR11:1) overbore .030. We left the stock ZZ3 cam in place.

Two weeks ago I went to the dyno where we experienced a clear detonation starting 4000rpm . We had to retard ignition down to 4� idle and 23� max advance above 3500rpm to get rid of knocking. ( 98 octane fuel used already ) This did not really give the hp I expected Engine lost lots of low end response / torque.

Now I read a lot about adding a hotter cam ( later ABDC seems to be the issue ) to bleed off pressure could solve my problem. ( cranking pressure was 175psi before, now it is 215psi )

Can somebody give me a recommendation how to move forward ?My goal is rather to get low end torque than high rpm power.

My combo:

Chevy ZZ3

portet heads

.30 overboreTRW pistons L2304F30 ( should give CR 11:1 accd to engine shop )

Ignition is MDS 6AL with electronical pickup, no vacuum.

Fuel is 98 Octane,

Cam ZZ3 stock

Heddman hot rod headers 1,5" primaries leading in 2" collector, opening to 2,5" tubes and Edelbrock RPM mufflers

Car is Cobra replica

TH350 manual shift kit

holeshot 2000 converter

3,07 rear end

I got a recommendation from grumpyvette for a crower cam, ( remember something like 00471 )

http://www.crower.com/misc/cam_spec/cam ... &x=59&y=12

heres the results

[/quote]

[/quote]

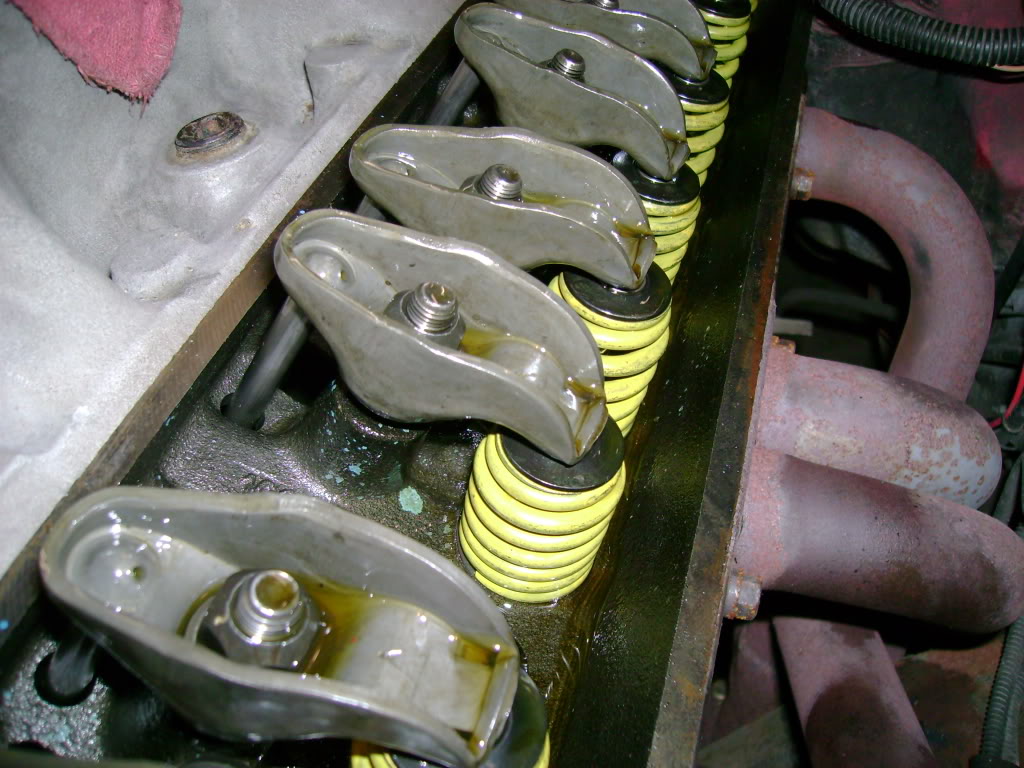

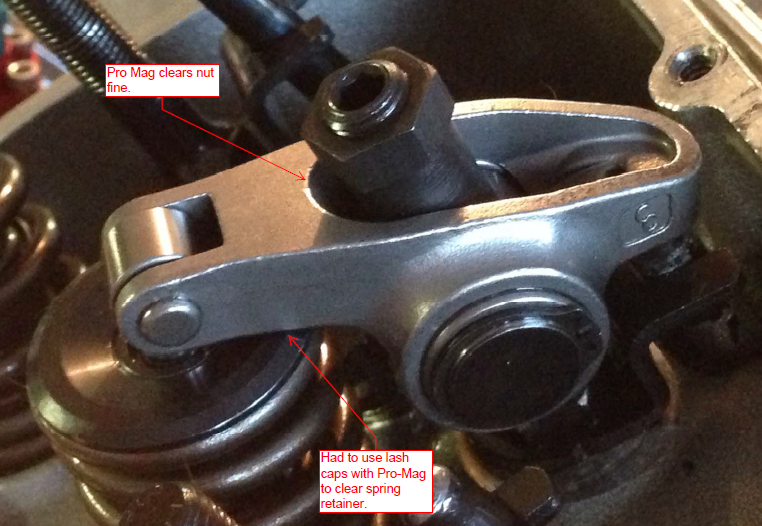

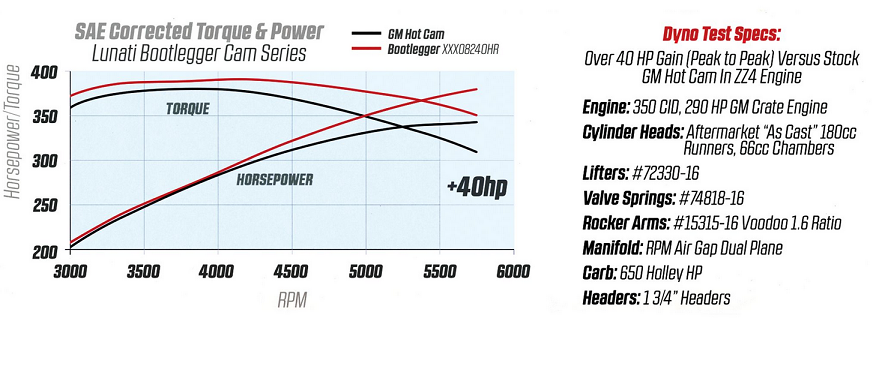

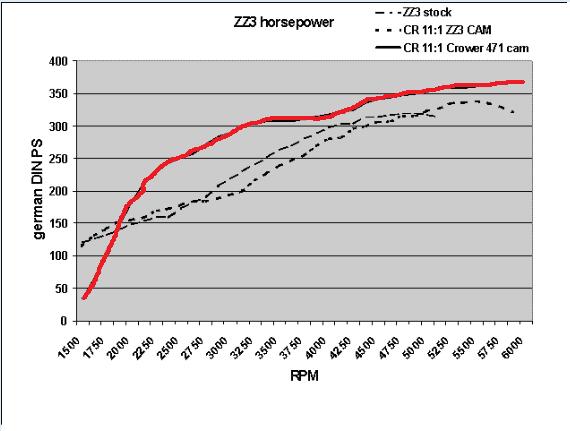

heres a good example of what a fairly well matched cam swap, with 11:1 compression, can do for the power curve, in this case a restrictive exhaust still limits power but yet its still a noticeable improvement

yoooooohaaaaaa !

I installed my engine today, got the CROWER 00471 cam installed with 6� retard. After adjusting my Webbers

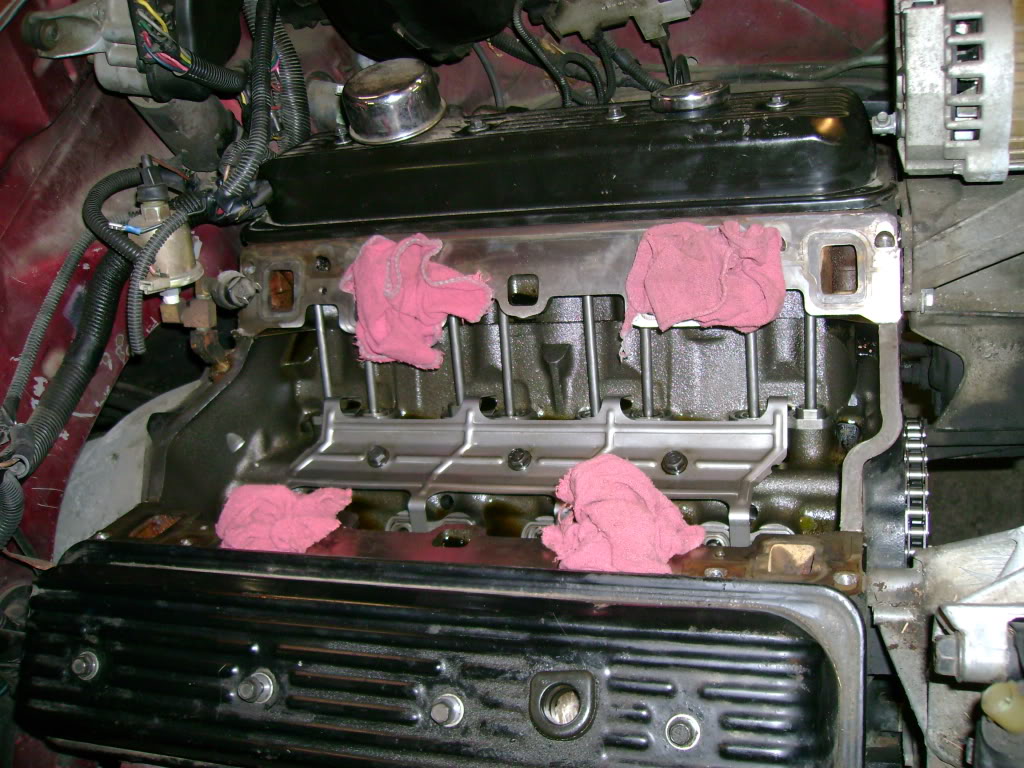

WHILE THESE PICTURES ARE NOT HIS CAR THE WEBERS and car WOULD BE SIMILAR

the idle is quite smooth, idling at 600-700 RPMs. Engine feels like it would be a new one, runs extremely soft when cruising.

But boy... if you hit the pedal the Webbers start screaming like hell.

I'll be at the dyno for final adjustment in 10 days. Will post results.

Ok folks, two days ago it was dyno time....

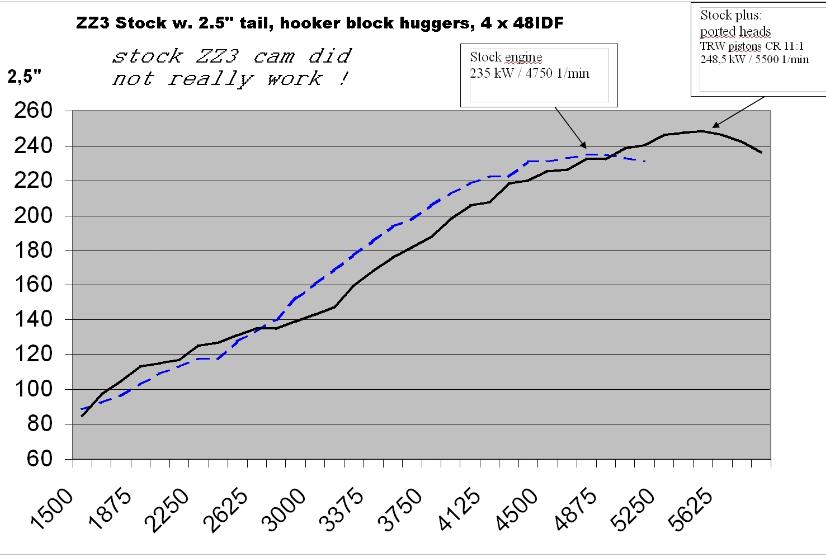

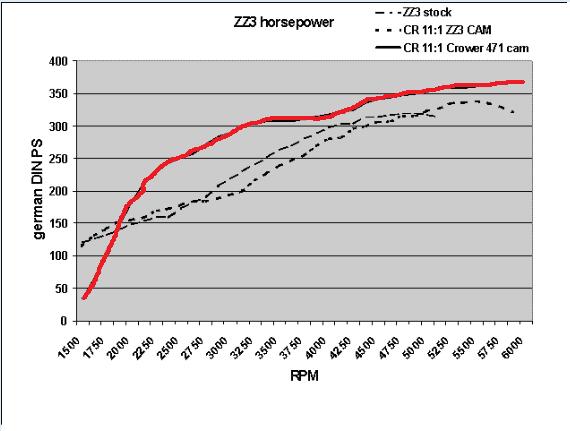

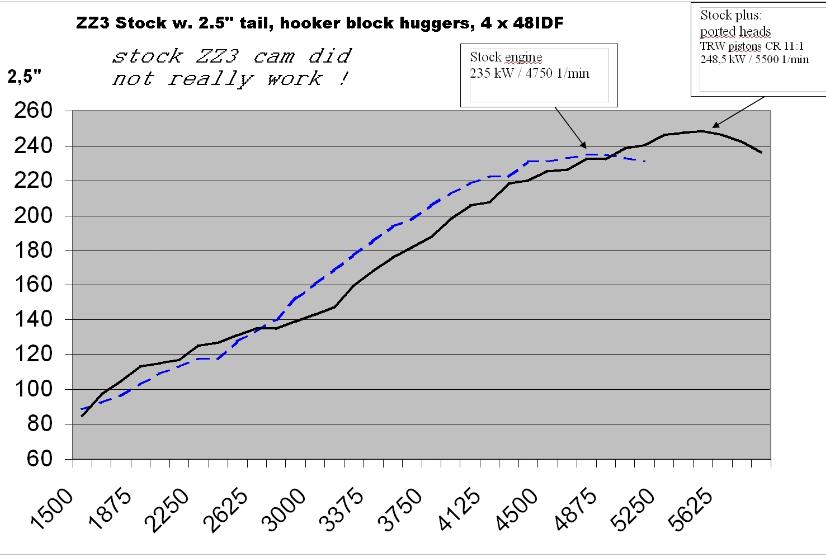

here you can see torque and hp of three stages of modification. peak dates first, tables & images follow later

the curve of the crower is FANTASTIC !!!

1. ZZ3 stock engine, no mods except my Webber 48 IDF carbs

2. same as 1, but heads ported plus TRW pistons added CR 11:1

3. same as two, but CROWER CAM 471 LM added, plus block hugger headers 1 1/2 replaced by 1 5/8 and tubing from collector to H-pipe increased from 2" to 2 1/2"

comments appreciated

1. 316 lbs ft @ 1.500 RPM, 319 hp @ 4.875 RPM

2. 425 lbs ft @ 1.875 RPM, 338 hp @ 5.500 RPM

3. 532 lbs ft @ 2.375 RPM, 361 hp @ 5.500 RPM

I do not care if the values itself are 100% correct, but having the same car on the same dyno, corrected by air temp & pressure should give correct relation.

my snake goes like...well, torque is fantastic, (in combination with a 3000 RPM stall converter that GRUMPY said needed to be matched to the cam) and TH350 manual shifter kit... my cobra at 2.400 pounds ---->>>>is butt kickin' boys !

Grumpy ! Thanks again for the fantastic recommendation on the CROWER

[CARLOS] story:hey grumpy...

I just got my chevy ZZ3 rebuilt.The engine shop did some porting work to the ZZ3 heads and added domed TRW pistons (CR11:1) overbore .030. We left the stock ZZ3 cam in place.

Two weeks ago I went to the dyno where we experienced a clear detonation starting 4000rpm . We had to retard ignition down to 4� idle and 23� max advance above 3500rpm to get rid of knocking. ( 98 octane fuel used already ) This did not really give the hp I expected Engine lost lots of low end response / torque.

Now I read a lot about adding a hotter cam ( later ABDC seems to be the issue ) to bleed off pressure could solve my problem. ( cranking pressure was 175psi before, now it is 215psi )

Can somebody give me a recommendation how to move forward ?My goal is rather to get low end torque than high rpm power.

My combo:

Chevy ZZ3

portet heads

.30 overboreTRW pistons L2304F30 ( should give CR 11:1 accd to engine shop )

Ignition is MDS 6AL with electronical pickup, no vacuum.

Fuel is 98 Octane,

Cam ZZ3 stock

Heddman hot rod headers 1,5" primaries leading in 2" collector, opening to 2,5" tubes and Edelbrock RPM mufflers

Car is Cobra replica

TH350 manual shift kit

holeshot 2000 converter

3,07 rear end

I got a recommendation from grumpyvette for a crower cam, ( remember something like 00471 )

http://www.crower.com/misc/cam_spec/cam ... &x=59&y=12

heres the results

heres a good example of what a fairly well matched cam swap, with 11:1 compression, can do for the power curve, in this case a restrictive exhaust still limits power but yet its still a noticeable improvement

yoooooohaaaaaa !

I installed my engine today, got the CROWER 00471 cam installed with 6� retard. After adjusting my Webbers

WHILE THESE PICTURES ARE NOT HIS CAR THE WEBERS and car WOULD BE SIMILAR

the idle is quite smooth, idling at 600-700 RPMs. Engine feels like it would be a new one, runs extremely soft when cruising.

But boy... if you hit the pedal the Webbers start screaming like hell.

I'll be at the dyno for final adjustment in 10 days. Will post results.

Ok folks, two days ago it was dyno time....

here you can see torque and hp of three stages of modification. peak dates first, tables & images follow later

the curve of the crower is FANTASTIC !!!

1. ZZ3 stock engine, no mods except my Webber 48 IDF carbs

2. same as 1, but heads ported plus TRW pistons added CR 11:1

3. same as two, but CROWER CAM 471 LM added, plus block hugger headers 1 1/2 replaced by 1 5/8 and tubing from collector to H-pipe increased from 2" to 2 1/2"

comments appreciated

1. 316 lbs ft @ 1.500 RPM, 319 hp @ 4.875 RPM

2. 425 lbs ft @ 1.875 RPM, 338 hp @ 5.500 RPM

3. 532 lbs ft @ 2.375 RPM, 361 hp @ 5.500 RPM

I do not care if the values itself are 100% correct, but having the same car on the same dyno, corrected by air temp & pressure should give correct relation.

my snake goes like...well, torque is fantastic, (in combination with a 3000 RPM stall converter that GRUMPY said needed to be matched to the cam) and TH350 manual shifter kit... my cobra at 2.400 pounds ---->>>>is butt kickin' boys !

Grumpy ! Thanks again for the fantastic recommendation on the CROWER

Last edited by a moderator: