You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

reusing head bolts...

- Thread starter DorianL

- Start date

Ok, I will venture an opinion on this. An over heated engine is a long ways from any temperature that would cause head bolts to lose any strength. Heat treating would take place at a much higher temperature, therefore you should be OK reusing them. I would be more worried about stretching a head bolt too far.

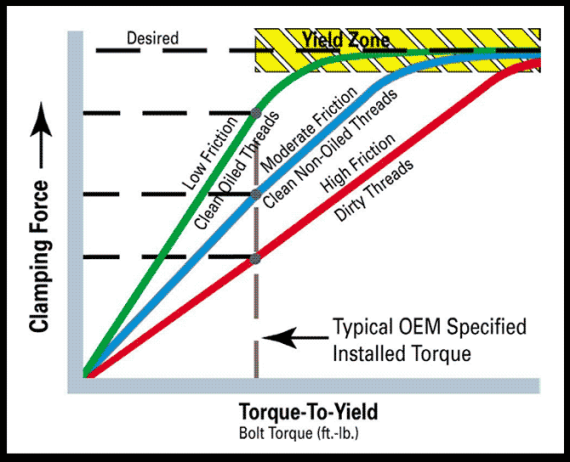

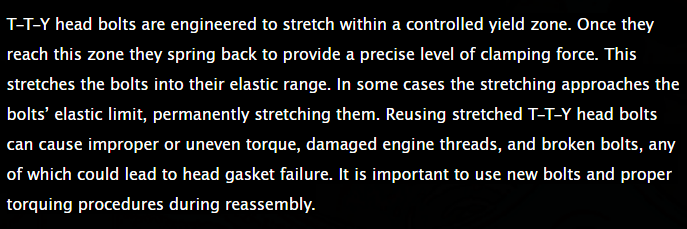

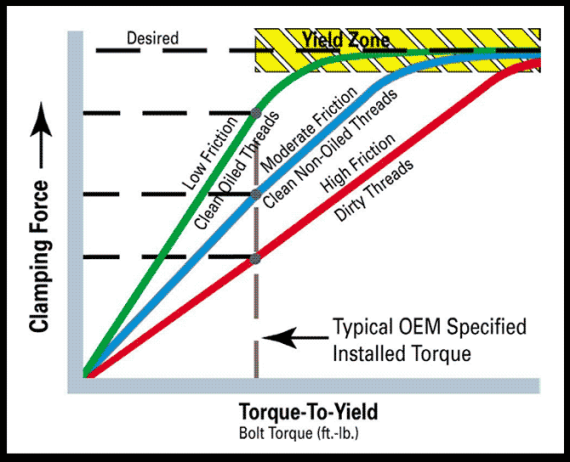

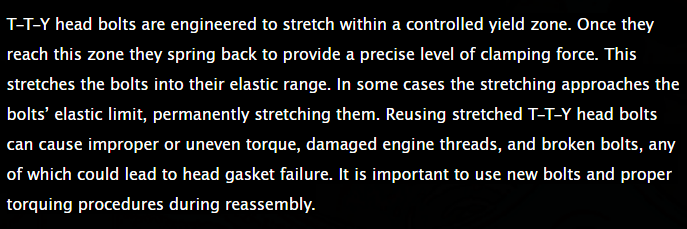

the correct answer on if you can re-use head bolts depends on the engine and TYPE of head bolts, typical ARP head bolts for first gen big and small blocks CAN BE reused several times as can STUDS, but the later engines use TORQUE TO YIELD BOLTS which are one time use bolts Ive never had the least problem with re-using the ARP head bolts on GEN1 SBC or BBC engines, some times for several rebuilds, I generally replace them only if they get damaged or used more than 6 times but hey, ask, ARP, if you have questions as they may have a different perspective, (but remember they are in the business to sell bolts)

they can be cleaned and reused ,provided they are in good condition, but you might want to think about upgrading to ARP bolts as it adds clamping force,

the arp bolts are stronger and more precisely made, but theres been many, many hundreds of thousands of sbc engines, that have been rebuilt with the stock head bolts being reused, and the threads coated with a decent sealant and a torque wrench used to tighten the bolts, so too infer that it won,t work correctly is ludicrous.

if you have the cash the ARP bolts are a good idea, if you don,t simply clean and reuse the stock bolts and use a torque wrench and the correct sealant, use the correct torque pattern and values and you'll do just fine.

be aware that head bolts enter the block coolant passages,

so if you failed to dip the bolt threads in sealant when they were assembled,

through the heads coolant can seep up along the head bolts,

into the area under the valve cover

btw read this

viewtopic.php?f=50&t=342&p=418#p418

viewtopic.php?f=50&t=1222&p=2750#p2750

viewtopic.php?f=44&t=700&p=1095&hilit=+sealant#p1095

both of these work great at sealing head bolt threads, and freeze plugs etc.

this should be used only in head bolt holes that don,t enter water jackets in the block

https://www.felpro.com/parts/engine-repair/head-bolt-sets.html

they can be cleaned and reused ,provided they are in good condition, but you might want to think about upgrading to ARP bolts as it adds clamping force,

the arp bolts are stronger and more precisely made, but theres been many, many hundreds of thousands of sbc engines, that have been rebuilt with the stock head bolts being reused, and the threads coated with a decent sealant and a torque wrench used to tighten the bolts, so too infer that it won,t work correctly is ludicrous.

if you have the cash the ARP bolts are a good idea, if you don,t simply clean and reuse the stock bolts and use a torque wrench and the correct sealant, use the correct torque pattern and values and you'll do just fine.

be aware that head bolts enter the block coolant passages,

so if you failed to dip the bolt threads in sealant when they were assembled,

through the heads coolant can seep up along the head bolts,

into the area under the valve cover

btw read this

viewtopic.php?f=50&t=342&p=418#p418

viewtopic.php?f=50&t=1222&p=2750#p2750

viewtopic.php?f=44&t=700&p=1095&hilit=+sealant#p1095

both of these work great at sealing head bolt threads, and freeze plugs etc.

this should be used only in head bolt holes that don,t enter water jackets in the block

https://www.felpro.com/parts/engine-repair/head-bolt-sets.html

Last edited by a moderator:

mathd said:Don't forget to put thread sealant on the bolt threads

this is what i use

I didnt know about thread sealant on freeze plug, i used ultra black for this.

let us know how that works out for you?

Ive used the other stuff linked to above on threads on head bolts and studs for decades without leaks

mathd

solid fixture here in the forum

Thats what i used on my 383 supercharged, i used brand new head bolt(not arp, i dont remember wich one actually) w/out thread sealant on them from the factory, not many miles spend with the engine yet but its doing its job so far.

Now you got me confused lol, I think that was the right product for head bolt when i build my engine because thats what i seen most guy use on other site/forums, i was wrong or right to use the product for my head bolt?

And i used ultra black on the intake bolt, i can't remember why :/

I also used it for the fuel line npt fittings(despite its not the appropriate product for the application) with good success

I also used some GREY anti-seize on the underside of the bolt head, apparently it help for bolt torque or something like that.

like this:

Now you got me confused lol, I think that was the right product for head bolt when i build my engine because thats what i seen most guy use on other site/forums, i was wrong or right to use the product for my head bolt?

And i used ultra black on the intake bolt, i can't remember why :/

I also used it for the fuel line npt fittings(despite its not the appropriate product for the application) with good success

I also used some GREY anti-seize on the underside of the bolt head, apparently it help for bolt torque or something like that.

like this:

larrym

Member

mathd said:Thats what i used on my 383 supercharged, i used brand new head bolt(not arp, i dont remember wich one actually) w/out thread sealant on them from the factory, not many miles spend with the engine yet but its doing its job so far.

Now you got me confused lol, I think that was the right product for head bolt when i build my engine because thats what i seen most guy use on other site/forums, i was wrong or right to use the product for my head bolt?

And i used ultra black on the intake bolt, i can't remember why :/

I also used it for the fuel line npt fittings(despite its not the appropriate product for the application) with good success

I also used some GREY anti-seize on the underside of the bolt head, apparently it help for bolt torque or something like that.

like this:

I'd be leary of never seize as a lube on head bolts or studs are there not different torque specs when using ARP moly lube vs conventional oil?

Especially a torque to yield 1 use type fastener.

http://arp-bolts.com/pages/technical_installation.shtml

northrnyankee

Well-Known Member

The bolt manufacturer should tell you what lubricant or thread sealer to use. Torque values when torquing by the head are higher than if torquing a nut onto a bolt. When I worked on aircraft by the books we added 10% to the torque of a bolt if taking the reading from the head and if that bolt was to be put in with a lubricant or sealer the drawing would give you the torque of that fastener. Regarding loctite I went on a few seminars when I worked on aircraft, if you use loctite thread sealer that would increase the force to break the bolt/nut free to 5% more than what the torgue value was on the bolt/nut. It was really quite interesting to see the frequency breaking cotter pins while the loctite was not affected.