What are your opinions about rhodes lifters?

http://www.rhoadslifters.com/Pages/OriginalFT.html

Rhoads lifters

Ive used them several times,do they work?

heres my opinion after using them in about 7 engines now!

if your asking do they effectively lower duration at low rpms and restore it at rpm levels exceeding about 3500 rpm then yes they do work! (but they don,t seem to be a magic cure for having picked the wrong cam in the first place like some people tend to think they are!) they also tend to be harder to adjust, noisy and generally not a huge improvement in performance, IF YOU'VE SELECTED THE CORRECT CAM IN THE FIRST PLACE .

they like many speed parts, are more a tuning aid that helps dial in a combo than a part that you can expect a big power increase from .

In many cases I see guys using them that think they will both compensate for selecting a cam that's got a bit too much duration for the ideal use on the street and also expect them to work almost like solid lifter flat tappet cam that typically give you 500rpm-1000rpm more in the power band than a a typical flat tappet hydraulic cam

they do tend to help on the low rpm, by effectively lowering duration just a bit at off idle to about 3500rpms, but Ive never seen any indication that they approach the effective rpm potential of a decent flat tappet solid lifter cam.

http://www.rhoadslifters.com/

http://www.rhoadslifters.com/Pages/Installation.html

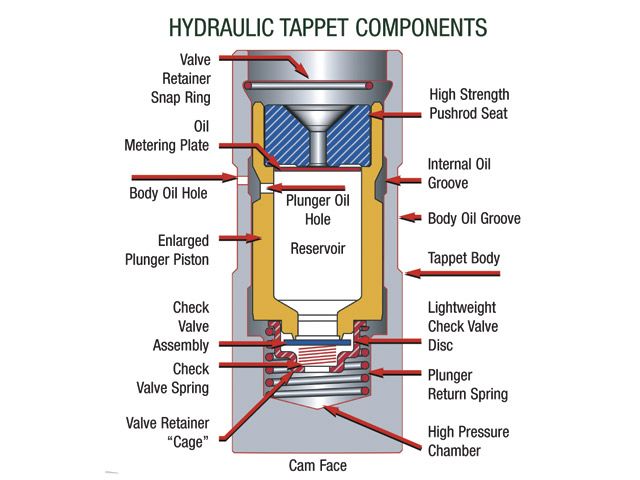

The effect of the Rhoads lifters is to allow the valves to close early at low rpm's, which means less duration for each lobe. as the push rod seat is not nearly as well supported with a cushion of compressed oil under lifters seat. The opening events are almost unchanged, because the oil under the lifter seat needs time to bleed off, but the closing events are advanced, and the results are like advancing the cam. The early closing intake valve increases the cranking pressure, the early closing exhaust valve reduces overlap and increases intake vacuum.

keep in mind they sound a bit like muted solid lifters because the lifter seats collapse much faster than standard hydraulics at idle speeds, because at idle they bleed off the oil under the lifters push-rod seat far faster, but as the rpm increases, the time required to bleed off that oil is significantly reduced resulting in the lifter lifting the valves over a longer duration as the rpms increase and time required to bleed off oil under the pushrod seats decreases

http://www.rhoadslifters.com/Pages/OriginalFT.html

Rhoads lifters

Ive used them several times,do they work?

heres my opinion after using them in about 7 engines now!

if your asking do they effectively lower duration at low rpms and restore it at rpm levels exceeding about 3500 rpm then yes they do work! (but they don,t seem to be a magic cure for having picked the wrong cam in the first place like some people tend to think they are!) they also tend to be harder to adjust, noisy and generally not a huge improvement in performance, IF YOU'VE SELECTED THE CORRECT CAM IN THE FIRST PLACE .

they like many speed parts, are more a tuning aid that helps dial in a combo than a part that you can expect a big power increase from .

In many cases I see guys using them that think they will both compensate for selecting a cam that's got a bit too much duration for the ideal use on the street and also expect them to work almost like solid lifter flat tappet cam that typically give you 500rpm-1000rpm more in the power band than a a typical flat tappet hydraulic cam

they do tend to help on the low rpm, by effectively lowering duration just a bit at off idle to about 3500rpms, but Ive never seen any indication that they approach the effective rpm potential of a decent flat tappet solid lifter cam.

http://www.rhoadslifters.com/

http://www.rhoadslifters.com/Pages/Installation.html

The effect of the Rhoads lifters is to allow the valves to close early at low rpm's, which means less duration for each lobe. as the push rod seat is not nearly as well supported with a cushion of compressed oil under lifters seat. The opening events are almost unchanged, because the oil under the lifter seat needs time to bleed off, but the closing events are advanced, and the results are like advancing the cam. The early closing intake valve increases the cranking pressure, the early closing exhaust valve reduces overlap and increases intake vacuum.

keep in mind they sound a bit like muted solid lifters because the lifter seats collapse much faster than standard hydraulics at idle speeds, because at idle they bleed off the oil under the lifters push-rod seat far faster, but as the rpm increases, the time required to bleed off that oil is significantly reduced resulting in the lifter lifting the valves over a longer duration as the rpms increase and time required to bleed off oil under the pushrod seats decreases

Last edited by a moderator: