great question,

first ID suggest that while its always nice to have super accurate precision tools its generally NOT critical in a basic engine rebuild to have the best or even close too the best measuring tools available.

now Im not suggesting accuracy is not important , but you seldom need accuracy to be less than than .0001 and some of the more expensive tools are designed to provide that level of accuracy, what you need is repeat-ability and consistency and the ability to get accuracy down to about .0002.

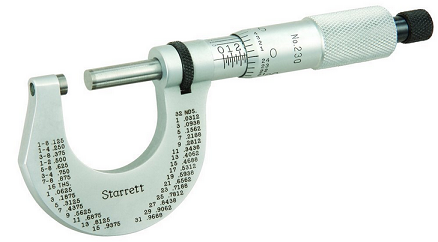

For measuring equipment Mitutoyo is tough to beat. The better stuff from Starrett is good as ,is the better quality tools from a few other sources.

I think youlll want to think thru how often youll use the tools and really how accurate you need to be ,take a step back and honestly ask your self, are you doing this often enough to invest a good amount of cash in tools you may not use more than once or twice a year or less, you have to ask yourself how much use the tools will get and how much having them will mean to you, I have several quality tools that I don't use enough on a consistent basis to really warrant their price they cost,but too me it was worth it to have them, and in most cases i got them at a discount (STILL DARN EXPENSIVE) so I could do the precision measurement work myself and do it right, and be sure of the results, but I,d be the first guy to admit I double check most bearing clearances with plasti-gauge strips

from a practical stand point, getting clearances in an engine down into less that a 1/4 of 1 thousandth (.00025 ) or less on the most critical components) and most down to (.0005 ) is usually sufficient, and on many even a full thousandth variation is not critical., example, a difference in rod side clearance, ring end gap or quench distance is far less critical than a thousandth difference in main bearing clearance, or piston to bore clearance.

now IM not suggesting the more expensive tools are not slightly better, but IM surprised at the level of accuracy the cheaper tools exhibit.

https://www.jegs.com/i/JEGS/555/805...MIq-XBhLiA3AIVV7nACh1zTQsNEAQYAiABEgKjkvD_BwE

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=dial+bore+gauge

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=dial+bore+gauge

READ THROUGH THIS LINKED THREAD

http://garage.grumpysperformance.com/index.php?threads/precision-measuring-tools.1390/#post-52469

http://www.summitracing.com/parts/cca-5605/overview/

http://www.jegs.com/i/JEGS+Performance+Products/555/81630/10002/-1

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=michrometer

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&Ntk=all&Jnar=0&itemPerPage=60&Ne=1+2+3+13+1147708&searchTerm=michrometer

http://www.amazon.com/Fowler-52-646...=1434331104&sr=1-1&keywords=fowler+52-646-400

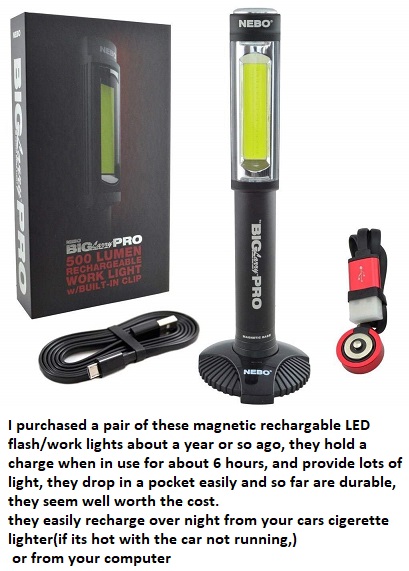

floridas hardly the ideal climate for keeping tools rust free so i generally take my set of micrometers out of the storage case and open and close them and spray them down with a light oil like WD 40 and place them back in the box then place the whole box in a 2 gallon zip lock bag in a shallow tupper ware type air tight storage box that is just the size to fit inside one of your tool chest drawers too protect the precision measuring tools , feeler gauges and plasti-gauge youll need to measure clearances correctly.when not in use along with the dial calipers.

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/

the reason I bring this up is I recently was over at a friends house where I needed to accurately measure a u-joint bearing cap and asked if he had a micrometer or dial caliper, he responded he had a very expensive looking imported micrometer, he had acquired recently at an estate yard sale for $30,

when he opened the very impressive looking brass and mahogany box the micrometer, inside was a solid rusted mass, I soaked it in marvel mystery oil and acetone mix for 30 minutes then gradually worked it loose and polished it up with 1500 grit wet/dry sand paper figuring no loss at this point and was amazed that after about 30 minutes of constant cleaning it not only looked fairly decent it seemed to read accurately on a test gauge so I think it was mostly ugly surface rust, but it sure looked horrible, and to someone who appreciates good tools,that was depressing.

btw look around at yard sales and estate sales every so often youll find amazing bargains in used precision tools

yes it sure helps to have the correct tools and know where to measure parts

http://www.tooltopia.com/fowler-72-646-300.aspx

http://www.harborfreight.com/3-piece-micrometer-set-66512.html

http://www.harborfreight.com/12-inch-di ... 47261.html

IVE got a wide selection of MICS and Calipers and IVE checked the cheap Chinese crap measurements and consistency against the much more expensive Japanese and American tools and surprisingly most are consistent , and reasonably accurate and decent quality if you get the stainless steel tools

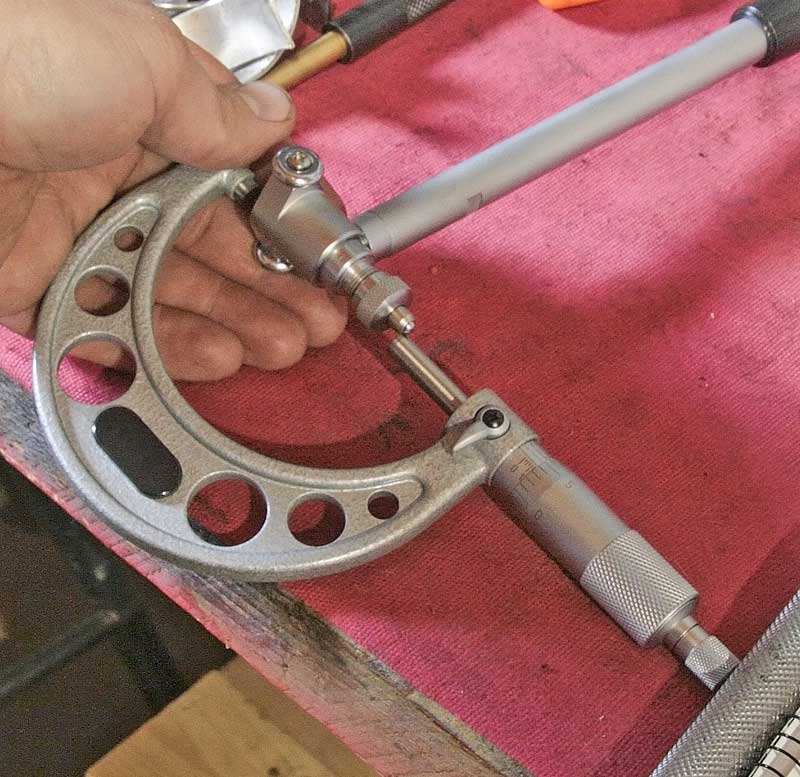

Mitutoyo, makes a good set that Ive had for years ( I bought a used set similar to the picture below, cheap at a yard sale, for $150 )

heres a cheap chinese import set, Ive used, a a friends house that work ok

http://grizzly.com/products/G5632

http://grizzly.com/products/2-6-Dial-Bore-Gage-Set/T24793

Ive found that a decent set of snap gauges and mics and a decent digital caliper will allow you to get bye quite nicely when used with some other checking tools, like plasti-gauge. repeatability and consistency are important.

plasti-gauge is an excellent cross check tool, easy to use and accurate, if used correctly, and I would not be a bit concerned if thats all you had to check bearing clearances, I use a fairly expensive set of mics, and snap gauges but I always cross check with plasti-gauge, and you ll be surprised at how accurate its really is

http://ecatalog.mitutoyo.com/Holtest-Ty ... C1530.aspx

even the cheapest Chinese tools are usually adequate

if you know what your doing, and are only using them occasionally and take care in carefully measuring components, and you verify with plasti Gage ,feeler gauges, and your consistent and take care during assembly

(SURELY NOT IDEAL BUT FULLY USABLE, frankly IM amazed at the cheap tool accuracy levels) I think a good deal of the reason is that once your down to clearances of a 1/2 thousand or less a few ten thousands difference are less a concern to durability than consistency and care taken in assembly and clearencing, and polishing, or smoothing parts

you'll need check standards to verify accuracy before each use, and you must keep the standards remain rust free in zip loc bags with a fine coat of wd40

it certainly helps to have a few tools that measure accurately

heres some info from napa

http://knowhow.napaonline.com/know-notes-measure-engine-bearing-clearance/

KNOW-HOW NOTES: HOW TO MEASURE ENGINE BEARING CLEARANCE

When rebuilding an engine, there is nothing more critical than getting the bearing clearance correct. Every engine has its own bearing clearance specs, but the measuring procedure does not change. There are two main methods used for checking bearing clearance –

Plastigage® or gauges.

Plastigage®

Plastigage® has its place, as it serves a purpose for backing up and verifying your bearing clearances. Plastigage® is a special plastic that expands a specific amount when squeezed. Sold in sleeves of threads for specific thickness ranges, Plastigage® works really well in situations where the components are not being completely removed, such as in-engine bearing replacement, and other non-automotive uses. Originally put on sale in 1948, Plastigage® is fairly accurate and the method of choice for many DIY enthusiasts.

Plastigage® is quite useful, so don’t automatically throw it out. It is a good way of verifying your measurements.

In reality, the right way to check bearing clearances is with the proper tools. In order to check the clearances for rod and main bearings, you need a set of

micrometers and a

dial-bore gauge. These are readily available at budget prices, but if you are going to use them a lot, better quality tools are advised.

Micrometer

This looks like a horseshoe with a round handle attached to one leg. Micrometers typically only adjust 1”, so you need multiple sizes to get the job done. A 1-6” set usually has the sizes you need for most jobs.

This a complete micrometer set that will cover just about anything you could need for automotive work.

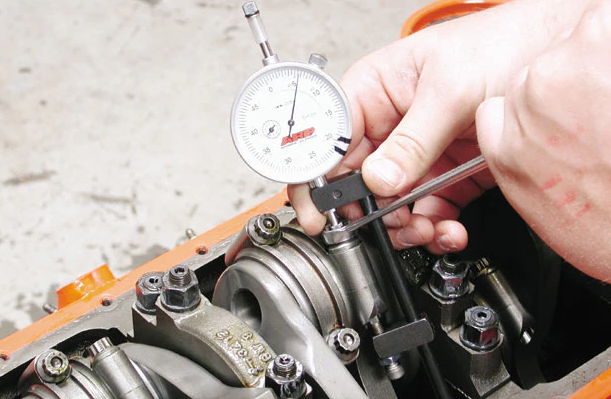

Dial-Bore Gauge

This tool uses a dial indicator on a post with a small wheeled measuring apparatus. These are adjustable through graduated post extenders that increase the diameter of the measurement circle.

The dial bore gauge measures the inside of round holes, such as the bearing journals.

http://garage.grumpysperformance.com/index.php?threads/bare-minimum-tools.11026/#post-51843

This one tool can measure 2″ up to 6″ diameter holes.

Both tools are needed in order to check the interior and exterior dimensions of the crankshaft, rods and engine block journals, as well as the thickness of the bearings themselves. Making all of this happen can be tricky, so here are a few tips to help you work through the process.

Using a micrometer means following a couple of rules. The key to a micrometer is not to tighten it too much. There are two knobs – a large knob and then a smaller one. The smaller knob clicks when the micrometer is in contract with the part. DO NOT use the larger knob to tighten the mic onto the part as this can damage the tool.

Reading a micrometer can be confusing, they are graduated differently than rulers. The inside barrel is marked in .100” (large) and .025” (small) notations. Once you reach those marks, the scale on the thimble (large rotating knob) comes into play to get the finite measurements. The thimble is scaled in .001 divisions from .000 up to .025”.

The hash marks are how you read micrometers. It takes some practice, and unless you use them daily, you will forget over time. Just be patient.

Outer Diameter Measurements

These are fairly simple, just choose the micrometer that covers the range needed and measure. It is a good idea to check the part in three different locations, staying away from the oiling holes as they can throw off the measurements due to the chamfers.

Measuring Bearings

Even though bearings are flat enough, they cannot be accurately measured with calipers, instead you need a micrometer. There are special micrometers available for measuring round inside surfaces, but you don’t have to have one of those. Instead, you can use the shaft of a drill bit (good quality, and use the smooth part, not the fluted section). Place the drill bit on the inside curve, and then measure the bearing. Subtract the thickness of the drill bit (measure, don’t assume), and you will have the thickness of the bearing.

An tube mic is useful for measuring bearings and over inside-curved pieces. In a pinch, you can use a drill bit or pushrod and an outside mic.

This is how bearings are measured. DO NOT use calipers, you can easily scratch the babbit material and ruin the bearing, plus they are just not accurate enough.

Using A Dial-Bore Gauge

Setting up a dial-bore gauge requires using a micrometer. You need the base measurement of the bore, rough is enough. Set the gauge to just over the diameter, using the correct extensions. Set the micrometer to the bore size you need, then place the gauge between inside the mic and rock the gauge back and forth, and side to side. Note the minimum reading, and zero the gauge to that reading.

Setting the dial bore gauge uses both the bore gauge and a micrometer. Make sure the measuring ends are square inside the micrometer’s anvils (not as shown)

Inside Diameter Measurements

With the dial-bore gauge set to the correct size, place the gauge inside the journal or rod end and rock the gauge back and forth and side to side, just like the setup process. Note the smallest diameter, that is the size of the journal. Just like the outside measurements, take the reading in three different places. One note – the bore must be as it would be in use, so torque the caps to their correct specs and they need to be clean, no oil at all.

Place the gauge inside the journal and move it slowly till you find the largest measurement. Take readings in three places.

checking standards

READ THRU THE LINKS AND SUB LINKS

or youll miss a great deal of related useful info

viewtopic.php?f=59&t=1026&p=4327&hilit=plasti+gauge#p4327

viewtopic.php?f=50&t=3157&p=8449#p8449

http://www.medfordtools.com/metalworking/123blocks.html

http://mechdb.com/index.php/Plastigagin ... clearances

http://arp-bolts.com/p/instructions.php

http://www.qualitymag.com/CDA/Archives/ ... 32a8c0____

https://www.travers.com/htdocs/pdf/0744cat.pdf

most micrometer sets come with check standards,but youll generally want a few extra sized ones, its important that you verify accuracy with them, remember heat expands metal, don,t expect parts that are warm to measure the same when its cool

http://www.wikihow.com/Use-and-Read-an- ... Micrometer

http://www.worldtools.com/tools/precisi ... p-971.html

http://video.google.com/videosearch?oe= ... Q&start=20

http://www.harborfreight.com/cpi/ctaf/d ... mber=97389

http://www.harborfreight.com/cpi/ctaf/d ... mber=66512

http://www.harborfreight.com/cpi/ctaf/d ... umber=5649

http://www.harborfreight.com/cpi/ctaf/d ... mber=32214

http://www.jegs.com/i/Mopar+Performance ... 9/10002/-1

hi grumpy had a question , im rebuilding a 350 chevy. the crank readings are main bearing journal is 2.448 and rod journals read 2.098 so does this mean that I would need standard sized bearings? and also when installing new bearing from the box , do I need to clean them and if so with what ...

garage.grumpysperformance.com

http://www.amazon.com/dp/B000HDF8N4/ref ... nkCode=asn