25C 70 said:Rebuilding a 70 l34. From what I've read it is more cost effective to buy new rods than re-bolt and re-size the originals. My question is what manufacturer is preferred and what bolt size 3/8 or 7/16. thanks.

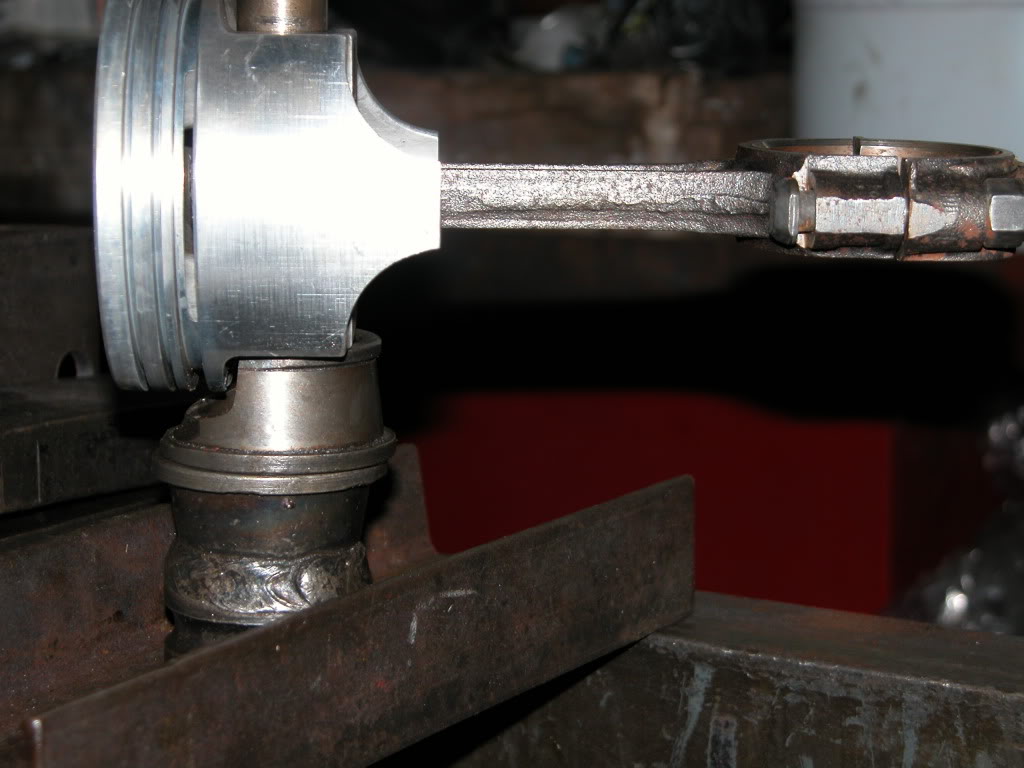

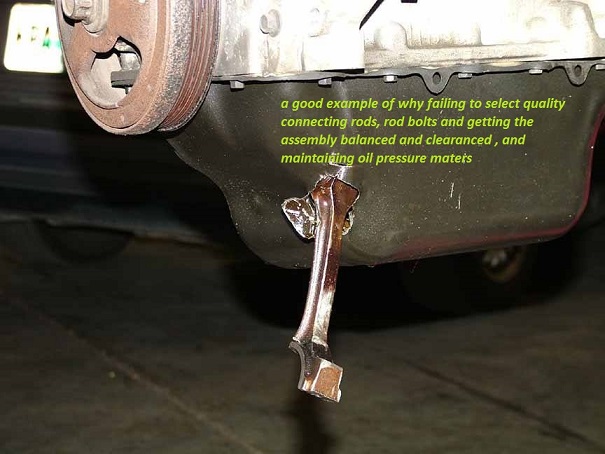

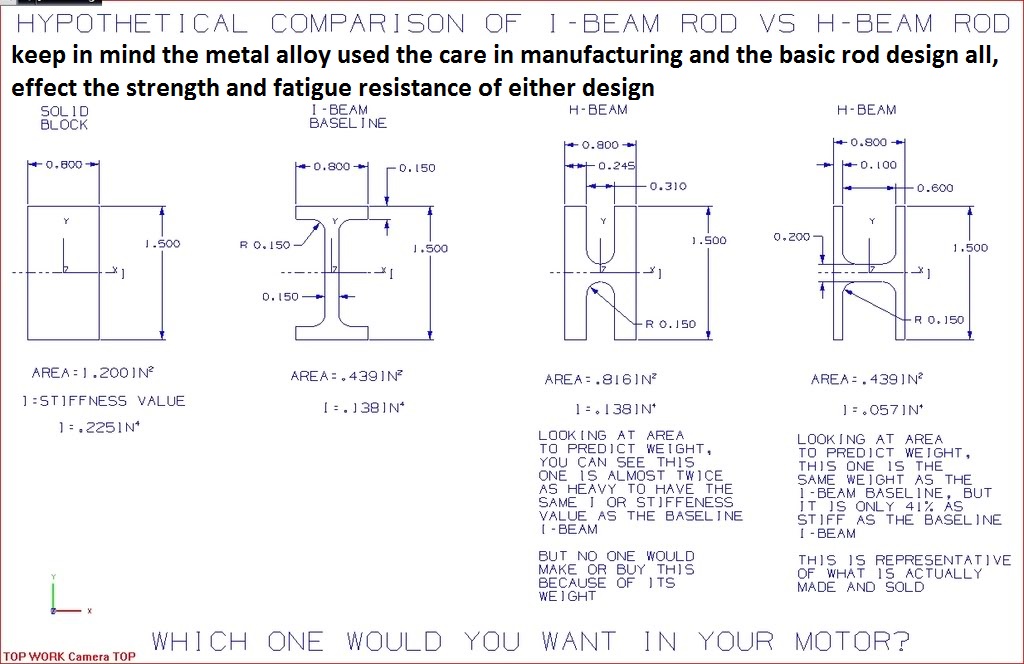

I know from long experience that the stock connecting rods, and pressed in pins that are pictured above are fully adequate for a stock rebuild ,but I would never personally re-use stock connecting rods without upgrading the rods with a careful polish resizing and bead blast, then,upgrading to ARP wave-lock rod bolts, but that is fairly expensive in most guys eyes, and in my mind is a total waste of time, as I vastly prefer far stronger 7/16" ARP rod bolt SCAT rods with the full floating pistons,pins and 4340 forged rods that allow easy self assembly and reassembly during the often repeated clearance checking procedures.

the reason is simple, by the time you pay to have the much stronger ARP rod bolts installed on stock rods and have them polished to remove stress risers the average machine shop parts and labor cost equals or exceeds the cost of the far stronger SCAT aftermarket rods.

http://www.superchevy.com/how-to/74038- ... ting-rods/

yes much of that labor could be done at home if you have the correct tools and know whats required,

http://www.summitracing.com/parts/arp-134-6403

http://www.tennesseespeedsport.com/Scat-26135-CHEVY-I-Beam-Rods.html

http://www.summitracing.com/parts/sca-2 ... /overview/

http://www.summitracing.com/parts/sca-26000716

http://www.summitracing.com/parts/sca-6600021

IVE used these connecting rods,with 7/16" ARP rod bolts, in most SBC 383-406 builds with complete success, but as mentioned always CHECK clearances

http://www.summitracing.com/parts/sca-26135

http://www.summitracing.com/parts/sca-26385716

and these with 7/16" ARP rod bolts,rods in most BBC builds with zero problems, I can,t imaging why anyone would use 3/8" rod bolts as they are a MINIMUM or 20% weaker due to the smaller cross sectional area, this larger 7/16" rod bolt,adds little weight for the significant strength upgrade

read this

viewtopic.php?f=53&t=510

viewtopic.php?f=53&t=1168&p=41255&hilit=polish+rods#p41255

http://www.tennesseespeedsport.com/Scat-25700716-CHEVY-I-Beam-Rods.html

far stronger than stock, SCAT rods with 7/16" ARP bolts (easily 200% over stock rods) cost less than having smaller diam 3/8" ARP rod bolts installed in the weaker stock rods then having the stock rods resized and polished for stress relief

READ THE LINKS

http://www.superchevy.com/how-to/74038-polish-connecting-rods/

http://www.hotrod.com/how-to/engine/ctrp-1012-race-engine-rebuild-tips/

http://www.hotrod.com/how-to/engine...building-factory-aftermarket-connecting-rods/

http://www.jensensenginetech.com/5-05_tech_tip.html

http://www.enginebuildermag.com/2007/04/performance-connecting-rods/

http://www.chevydiy.com/crankshafts-connecting-rods-pistons-guide-chevy-big-blocks/

Last edited by a moderator: