because this question comes up regularly Ill address, it with a few facts and let you make your own minds up.

the question is usually stated like ("hey grumpyvette? can I get by with the less expensive roller tip rockers or are full roller rockers required/, or can I just continue to use the factory stamped rockers?")

ok,let me point out first the stock production stamped steel rockers are rarely at a true 1.5:1 ratio and finding some vary at between a ratio of 1.47-1.52:1, is very common, they are not all that efficient and the friction levels and heat generated are fairly high especially under high rpms and higher than stock spring loads, do they work, yes they do but their main asset is low cost.

most guys fail to realize how much heat the rockers valve springs and assorted valve train components generate, but tests show that 35% or more of engine heat is not the result of combustion , but friction, and most of that heats generated in the valve train, rockers without a constant flow of oil will quickly pressure weld, the stamped steel rockers to the rocker balls, and valve springs will heat up enough to loose their temper and strength.

swapping to full roller rockers, alone commonly reduces engine oil temperatures, by 7-12 degrees

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

and if your regularly exceeding 6500rpm and 400 lbs of open valve spring load rate its use is going to become almost mandatory

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

cost generally runs in the $50-$90 range for a set, but dealerships can charge a good deal more

http://www.summitracing.com/parts/SUM-G6801/

aftermarket stamped rockers with roller tips tend to have a more consistent ratio, and many are made to closer tolerances, but the friction levels are still very high because about 90% plus of the friction is in the rocker ball pivot point, riding in the stamped rocker body,rotating on the rocker stud, the rollers on the tip contacting the valve are mostly for looks as the rocker tip rarely moves more than about .030-.050 thousands MAXIMUM on the valve tip in a correctly set up valve train geometry, so its roller function is minimal at best, gains of 3-5 hp are common IF you go to the higher 1.6:1 ratios, are used,vs the stock 1.5:1 ratio rockers,, mostly the gains are more the result of more consistent ratio control and a bit of extra lift,with the higher ratio. If your going to use the stock 1.5:1 ratio, that usually results in slightly lower gains , as the rocker ratio consistency, over stock rockers , still helps but the roller tips add VERY little to the valve train efficiency, but the more consistent ratio control helps........Ive generally advised going to, ERSON,COMP,CRANE or CROWER full roller rockers, vs roller tip rockers, because of the reduced friction that drops oil temperatures and reduced wear,on the valve guides and the 15-20 hp that's frequently gained

roller tip rockers generally cost $90-$200

http://www.summitracing.com/parts/SUM-141507/

http://www.midwestmotorsportsinc.com/in ... 1&parent=0

http://www.summitracing.com/parts/SUM-141506/

true roller rockers can cost between about $219-$600 plus, depending on the application

TRUE FULL roller rockers generally reduce heat and friction significantly, an increase of 15-20hp is fairly common

http://www.summitracing.com/parts/CCA-1602-16/

http://www.midwestmotorsportsinc.com/in ... 8&parent=0

IVE USED ERSONS EXTREME DUTY ROLLER ROCKERS IN MANY ENGINES OVER MANY YEARS WITH COMPLETE SATISFACTION (notice those are NOT the standard roller rockers they sell)

http://www.pbm-erson.com/store.php?catId=481&parent=24

http://www.usaperform.com/extreme-duty- ... p-849.html

at about $250 these are a bargain

most roller rockers that FAIL are the result of LOW LUBRICATION,flow rates, or EXTREME VALVE SPRINGS loads or improper valve train geometry, OR FAILURE TO CHECK CLEARANCES AND VALVE TRAIN GEOMETRY CAREFULLY,

if your running a flat tappet cam on the street,those cams tend to have far lower load rates and ramp acceleration rates than roller cams, so the rockers take less abuse, just make sure the peak valve spring load rates stay under about 400 lbs,(preferably under 350 lbs) and your valve train geometry is correct and a good quality roller rocker , thats constantly bathed in CLEAN oil will last about 30K-40K plus miles, in my experience, obviously not restricting oil to the upper engine,changing oil regularly and naturally inspecting them when you adjust the valves and use of a stud girdle on the rocker studs helps

http://www.summitracing.com/parts/CRO-75115/

shaft rockers are generally more stable, under high rpm and spring load rates but cost in the $800-$1600 range depending on the application

take the effort to read thru these sub links as theres a good deal more info

http://www.vetteweb.com/tech/vemp_0703_ ... index.html

viewtopic.php?f=52&t=2746

http://www.vetteweb.com/tech/0204vet_sm ... index.html

viewtopic.php?f=52&t=196

viewtopic.php?f=52&t=181&p=7436&hilit=rockers+ratio#p7436

viewtopic.php?f=52&t=689

viewtopic.php?f=52&t=181&p=7156&hilit=rockers+ratio#p7156

viewtopic.php?f=52&t=2632&p=6790&hilit=+rockers+ratio#p6790

viewtopic.php?f=52&t=126&p=1270&hilit=+rockers+ratio#p1270

viewtopic.php?f=52&t=663&p=911&hilit=+girdle+rocker#p911

http://www.youtube.com/watch?v=DxROQtv7 ... r_embedded

LOOK CLOSELY he OBVIOUSLY had the clearances wrong, look at the inner area where the rocker stud adjustment nut has worn a a significant polished area where it was badly miss aligned, now proform may not be nearly (TOP OF THE LINE) but looking at the evidences strongly suggests a clearance issue or geometry issue with the valve train was a major factor in the rocker failure. I see guys knock the parts manufacturers all the time and at times its valid, but many times when parts fail its improper installation, or lack of knowledge as to proper procedures or how to check clearances or geometry.

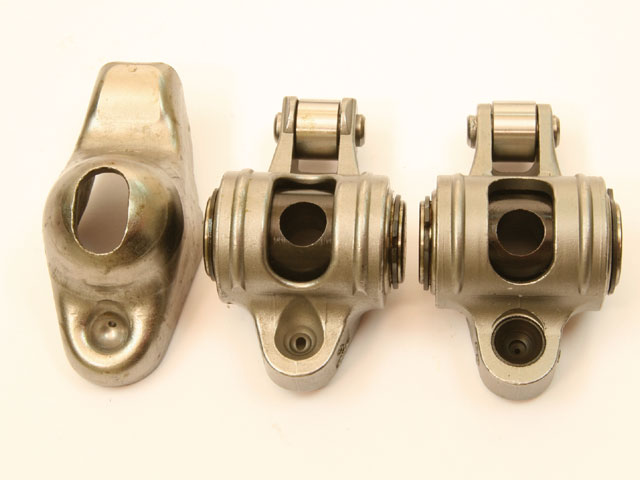

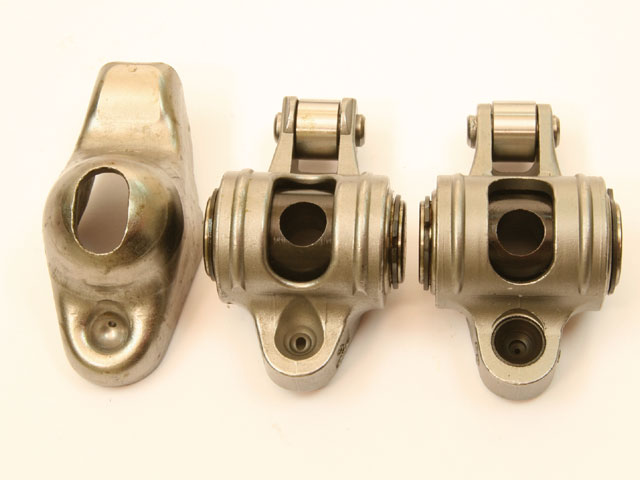

btw heres a better rocker design

in this picture the self aligning rocker is the center one with the raise ridges that keep in centered on the valve tip , the two end rocker require guide plates

self aligning stamped rocker

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=2746

guide plates and screw in studs or

self aligning rockers have ridges to prevent the rocker from moving off the valve stem

the question is usually stated like ("hey grumpyvette? can I get by with the less expensive roller tip rockers or are full roller rockers required/, or can I just continue to use the factory stamped rockers?")

ok,let me point out first the stock production stamped steel rockers are rarely at a true 1.5:1 ratio and finding some vary at between a ratio of 1.47-1.52:1, is very common, they are not all that efficient and the friction levels and heat generated are fairly high especially under high rpms and higher than stock spring loads, do they work, yes they do but their main asset is low cost.

most guys fail to realize how much heat the rockers valve springs and assorted valve train components generate, but tests show that 35% or more of engine heat is not the result of combustion , but friction, and most of that heats generated in the valve train, rockers without a constant flow of oil will quickly pressure weld, the stamped steel rockers to the rocker balls, and valve springs will heat up enough to loose their temper and strength.

swapping to full roller rockers, alone commonly reduces engine oil temperatures, by 7-12 degrees

its not horsepower, its the stress on the valve train, that makes a rocker stud girdle and its increased rigidity useful,

and thats more closely related to average stress levels, RPM and VALVE SPRING LOAD RATES

any time your occasionally exceeding 6000rpm or getting close too 330 lbs of open valve load rate Id strongly suggest screw in rocker studs

any time your intentionally exceeding 6000rpm and exceeding 350 lbs of open valve spring rate a rocker stud girdle might be a good idea.

and if your regularly exceeding 6500rpm and 400 lbs of open valve spring load rate its use is going to become almost mandatory

http://www.summitracing.com/parts/pro-66950

http://www.summitracing.com/parts/sum-141010

cost generally runs in the $50-$90 range for a set, but dealerships can charge a good deal more

http://www.summitracing.com/parts/SUM-G6801/

roller tip rockers generally cost $90-$200

http://www.summitracing.com/parts/SUM-141507/

http://www.midwestmotorsportsinc.com/in ... 1&parent=0

http://www.summitracing.com/parts/SUM-141506/

true roller rockers can cost between about $219-$600 plus, depending on the application

TRUE FULL roller rockers generally reduce heat and friction significantly, an increase of 15-20hp is fairly common

http://www.summitracing.com/parts/CCA-1602-16/

http://www.midwestmotorsportsinc.com/in ... 8&parent=0

IVE USED ERSONS EXTREME DUTY ROLLER ROCKERS IN MANY ENGINES OVER MANY YEARS WITH COMPLETE SATISFACTION (notice those are NOT the standard roller rockers they sell)

http://www.pbm-erson.com/store.php?catId=481&parent=24

http://www.usaperform.com/extreme-duty- ... p-849.html

at about $250 these are a bargain

most roller rockers that FAIL are the result of LOW LUBRICATION,flow rates, or EXTREME VALVE SPRINGS loads or improper valve train geometry, OR FAILURE TO CHECK CLEARANCES AND VALVE TRAIN GEOMETRY CAREFULLY,

if your running a flat tappet cam on the street,those cams tend to have far lower load rates and ramp acceleration rates than roller cams, so the rockers take less abuse, just make sure the peak valve spring load rates stay under about 400 lbs,(preferably under 350 lbs) and your valve train geometry is correct and a good quality roller rocker , thats constantly bathed in CLEAN oil will last about 30K-40K plus miles, in my experience, obviously not restricting oil to the upper engine,changing oil regularly and naturally inspecting them when you adjust the valves and use of a stud girdle on the rocker studs helps

http://www.summitracing.com/parts/CRO-75115/

shaft rockers are generally more stable, under high rpm and spring load rates but cost in the $800-$1600 range depending on the application

take the effort to read thru these sub links as theres a good deal more info

http://www.vetteweb.com/tech/vemp_0703_ ... index.html

viewtopic.php?f=52&t=2746

http://www.vetteweb.com/tech/0204vet_sm ... index.html

viewtopic.php?f=52&t=196

viewtopic.php?f=52&t=181&p=7436&hilit=rockers+ratio#p7436

viewtopic.php?f=52&t=689

viewtopic.php?f=52&t=181&p=7156&hilit=rockers+ratio#p7156

viewtopic.php?f=52&t=2632&p=6790&hilit=+rockers+ratio#p6790

viewtopic.php?f=52&t=126&p=1270&hilit=+rockers+ratio#p1270

viewtopic.php?f=52&t=663&p=911&hilit=+girdle+rocker#p911

http://www.youtube.com/watch?v=DxROQtv7 ... r_embedded

LOOK CLOSELY he OBVIOUSLY had the clearances wrong, look at the inner area where the rocker stud adjustment nut has worn a a significant polished area where it was badly miss aligned, now proform may not be nearly (TOP OF THE LINE) but looking at the evidences strongly suggests a clearance issue or geometry issue with the valve train was a major factor in the rocker failure. I see guys knock the parts manufacturers all the time and at times its valid, but many times when parts fail its improper installation, or lack of knowledge as to proper procedures or how to check clearances or geometry.

btw heres a better rocker design

in this picture the self aligning rocker is the center one with the raise ridges that keep in centered on the valve tip , the two end rocker require guide plates

self aligning stamped rocker

viewtopic.php?f=52&t=181

viewtopic.php?f=52&t=2746

guide plates and screw in studs or

self aligning rockers have ridges to prevent the rocker from moving off the valve stem

Last edited by a moderator: