Wonder what everyone thinks of this: True? False? Good idea? Or Bad?

From Don Terrill's Speed Talk thread https://www.speed-talk.com/forum/viewtopic.php?f=1&t=852

"GM owners found using larger throttle openings at lower RPMs trades to improve fuel economy, found increased main bearing wear.

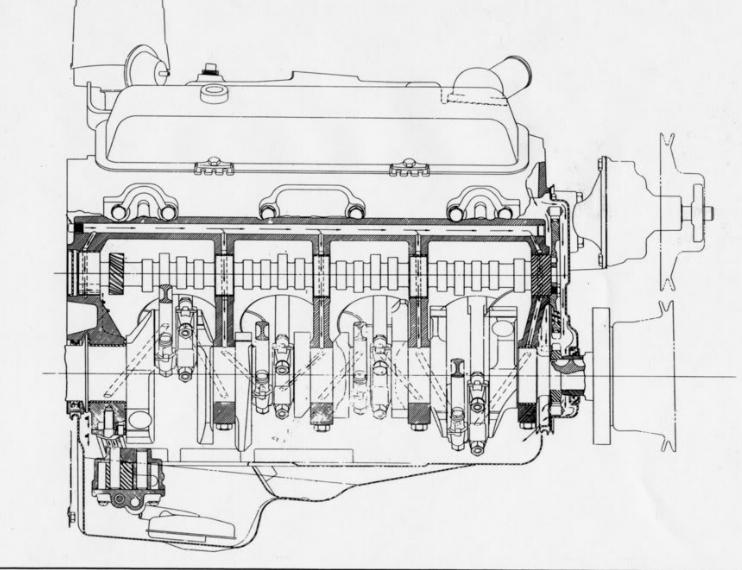

For fifty years, the SBC pulling a three-speed tranny at 2500+ RPMs never had main bearing issues.

When the lockup/overdrive came along and computer controls allowed pulling near-WOT at 1900 RPMs, the main bearing problems began."

My 383 is being built to run at 1500RPMs and my plan is do that when cruising thanks to a second overdrive transmission.

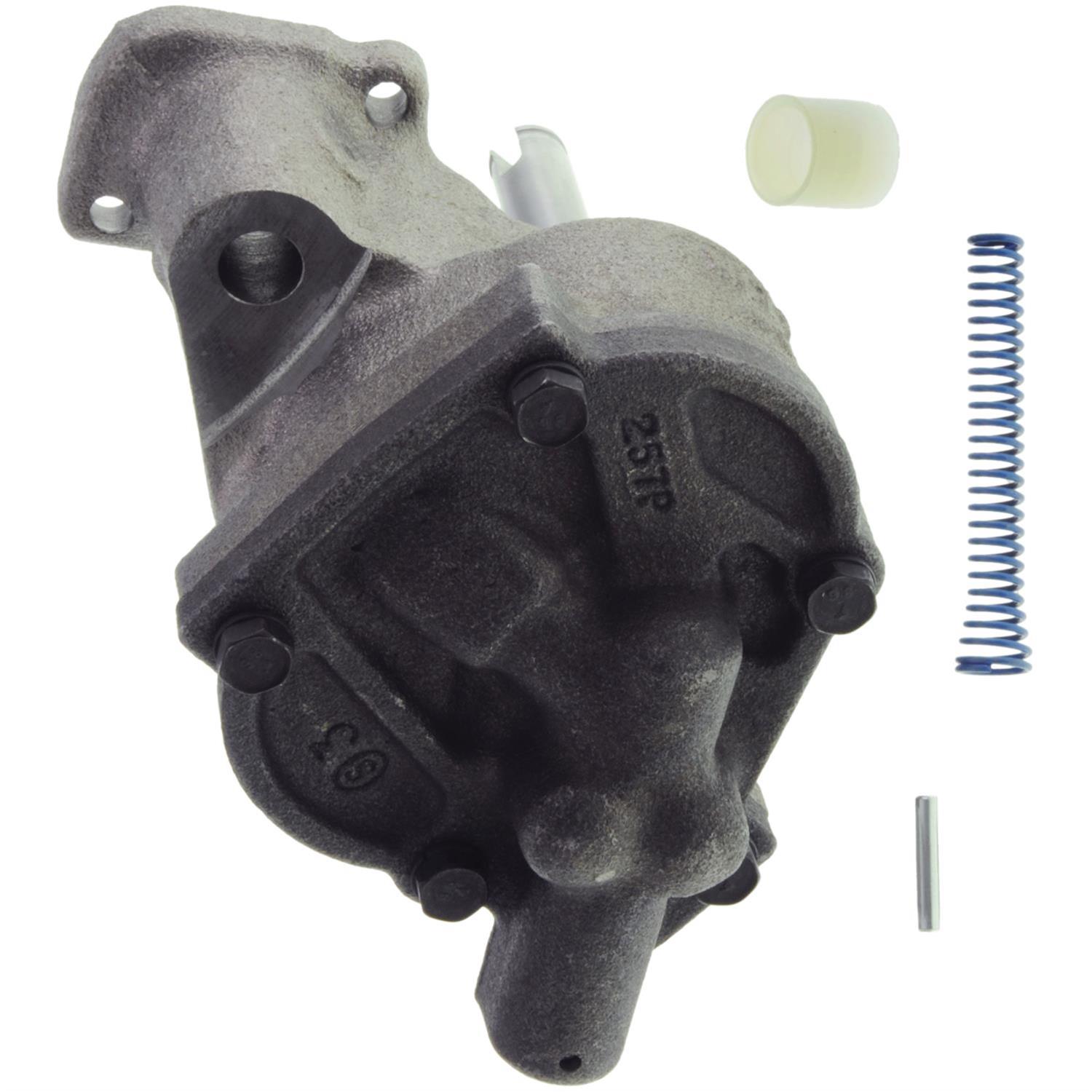

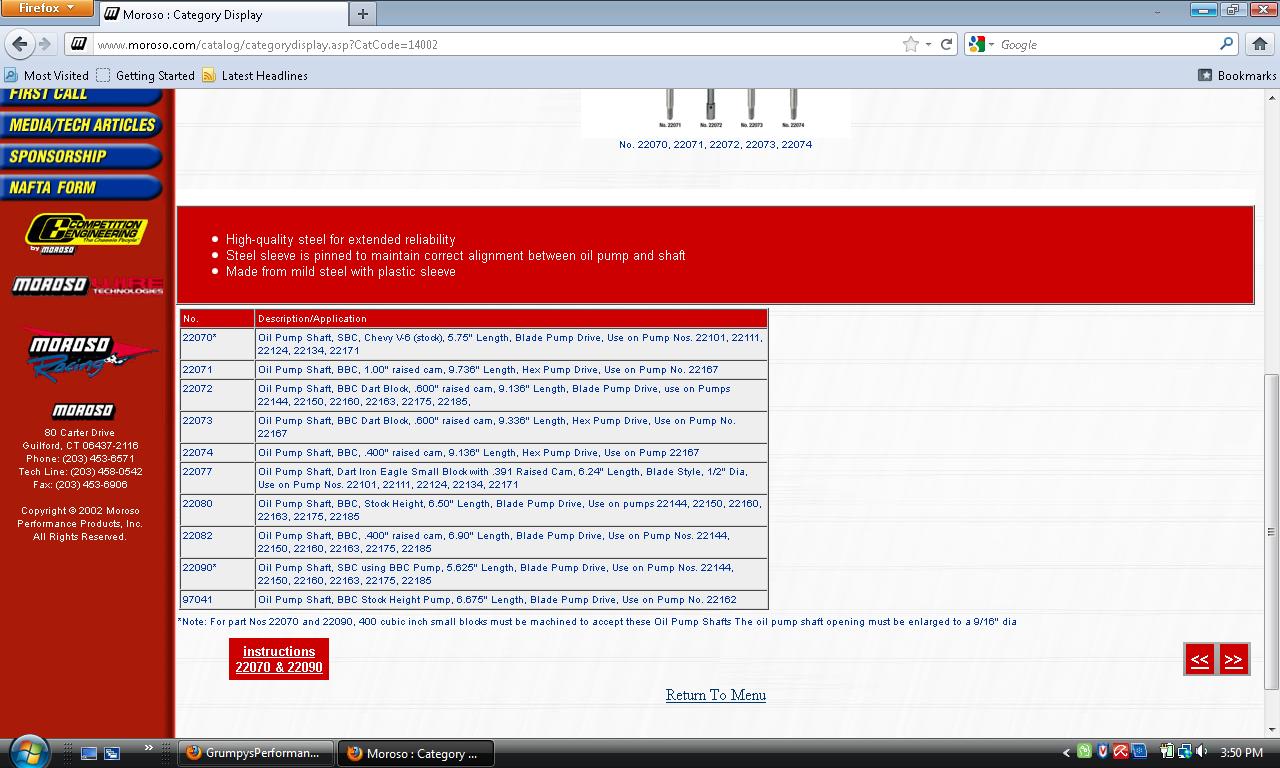

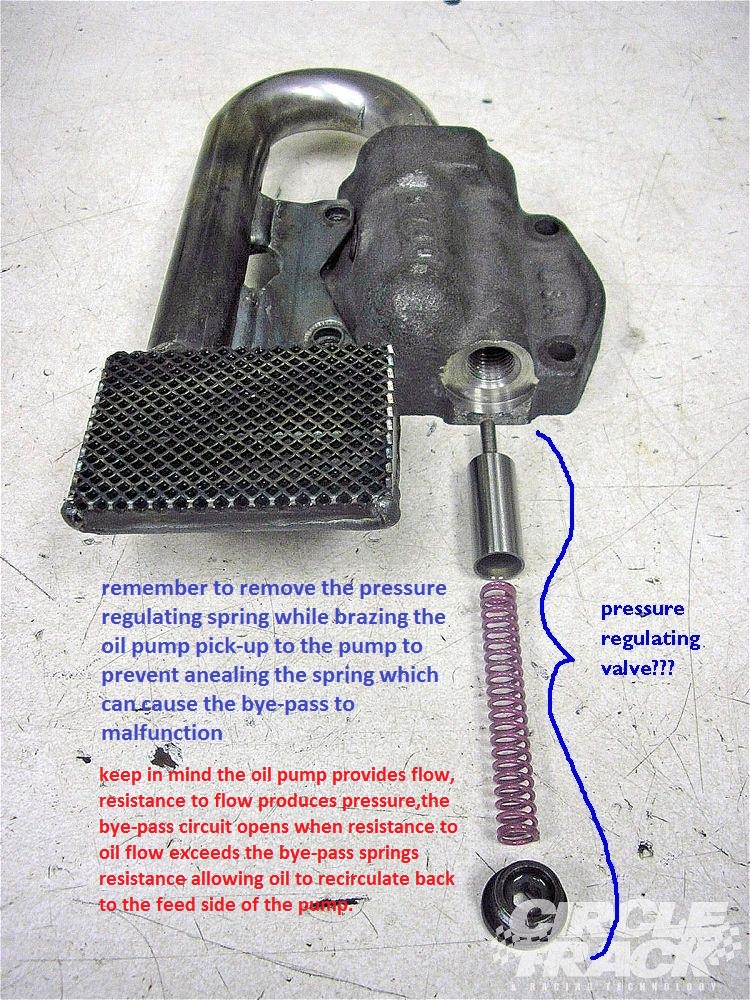

So I now think a high volume oil pump is called for....plus the resulting higher oil pressure should pump up my Rhoads Lifters sooner...moving their peak from 3500RPMs hopefully to 3000.

From Don Terrill's Speed Talk thread https://www.speed-talk.com/forum/viewtopic.php?f=1&t=852

"GM owners found using larger throttle openings at lower RPMs trades to improve fuel economy, found increased main bearing wear.

For fifty years, the SBC pulling a three-speed tranny at 2500+ RPMs never had main bearing issues.

When the lockup/overdrive came along and computer controls allowed pulling near-WOT at 1900 RPMs, the main bearing problems began."

My 383 is being built to run at 1500RPMs and my plan is do that when cruising thanks to a second overdrive transmission.

So I now think a high volume oil pump is called for....plus the resulting higher oil pressure should pump up my Rhoads Lifters sooner...moving their peak from 3500RPMs hopefully to 3000.

Last edited: