steve65 said:Please forgive me if I'm asking a stupid question but, when setting the initial timing on my small block do I drop the distributor in at 0 degrees (TDC) with the rotor pointing to #1 cylinder on the cap or should the pointer on the timing tab be pointed at 10 degrees advanced to get my initial timing. The reason I'm asking is it pulls strong to about 3000-3500 rpm then starts to crap out and buck and surge until I let me foot off it.

Thanks for any help you may be able to provide.

step one

verify TDC

http://garage.grumpysperformance.com/index.php?threads/finding-top-dead-center.967/

STEP

two VERIFY your ignition timing and function

http://garage.grumpysperformance.com/index.php?threads/verifying-your-real-advance-curve.4683/

http://garage.grumpysperformance.com/index.php?threads/timing-lights.875/

http://garage.grumpysperformance.com/index.php?threads/timing-tabs-and-indicators.1015/

http://garage.grumpysperformance.co...ouble-shooting-rebuilding-hei-ignitions.2798/

step three

never assume the problem

is limited too ignition issues UNTIL YOU PROVE IT AND CORRECT IT

http://garage.grumpysperformance.co...conductive-grease-for-ignition-modules.10748/

http://garage.grumpysperformance.com/index.php?threads/how-altenators-work.355/

http://garage.grumpysperformance.com/index.php?threads/reading-plugs.5428/

http://garage.grumpysperformance.com/index.php?threads/burning-out-distributor-modules.3797/

http://garage.grumpysperformance.com/index.php?threads/distributor-gear-wear.1701/#post-5252

http://garage.grumpysperformance.co...stalling-the-intake-manifold-distributor.464/

you might also have a fuel delivery

(fuel pump, or fuel filter)

or valve train

worn cam lobe,

cam timing gear,

weak or broken valve springs,

a restrictive catalytic converter,

restrictive exhaust,

related issue,

a bad alternator bad spark plugs or a dozen other issues that NEED to be checked!

NEVER GUESS CHECK EVERYTHING.

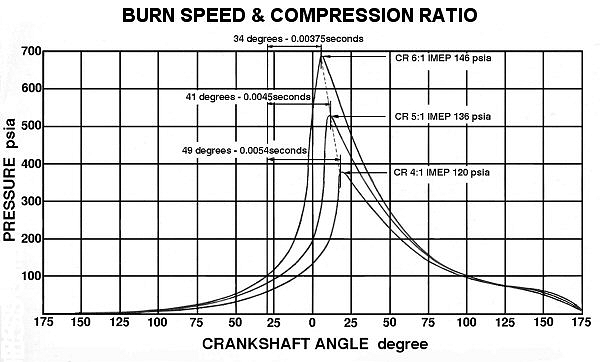

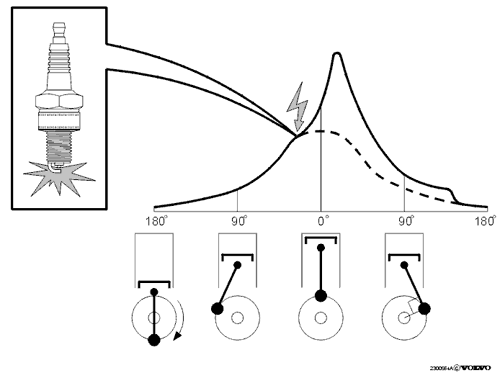

if your ignition advance is too rapid or goes past about 40 degrees its likely to cause detonation as too much cylinder pressure builds before the piston passes TDC, not after where it can do work as designed

your torque is basically related to how effectively you build and use cylinder pressure and your engines displacement.

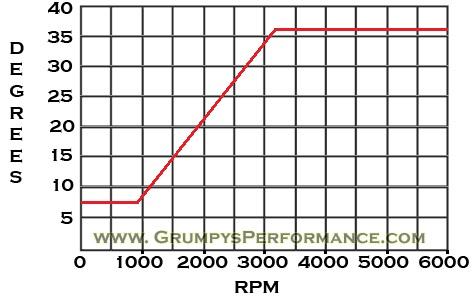

as long as most of the cylinder pressure builds after the crank throw passes TDC, the pressure in the cylinder is used to push the piston down on the power stroke and make power, any pressure built before the crank rotation reaches TDC reduces power as it resists rotation, keep in mind at low rpms it takes about 30-50 thousands of a second to burn a cylinder of f/a mix, as the rpms increase the time required to burn the compressed mix decreases due to several factors like squish and turbulence, but at low rpms you don,t need a great deal of ignition advance because at 1000rpm your only getting 500 power strokes per minute per cylinder, or about 8 power strokes every second, so 6-8 degrees advance allows plenty of time to build pressure above the piston, as it reaches and passes TDC, and have most of that pressure build after tdc in crank rotation.

BUT if you increase the rpms to 3000rpm and youve cut the available burn time into less than a third, so ignition needs to occur sooner in the rotation, thus the need to advance the ignition point in relation to piston movement compressing the fuel/air mix, but as rpms continue to increase the flame pattern advance due to constantly being compressed faster and more violently, decreases the need for further increased ignition advance at some point, usually at about 3200rpm, where your ignitions usually fully advanced

ONCE YOU PLOT THE ADVANCE CURVE IT WILL LOOK SIMILAR TO THIS

Last edited by a moderator: