I would NOT suggest, modifying the current oil pump design by drilling a vent hole to be used for by-passing the higher pressure oil, back to the oil pan, sump, directly.

as in several tests, Ive seen posted over the decades, it was proven to result in a constantly pulsing jet of high pressure oil aerating the sump oil, this causes the oil pump pick-up to suck in a mix of air & oil thats is not nearly as effective ate lubing or cooling bearings, pistons etc.

routing high pressure oil back to the low pressure side of the oil pump is generally the more effective approach, now you can enlarge and smooth that return oil passage, to reduce resistance to oil flow.

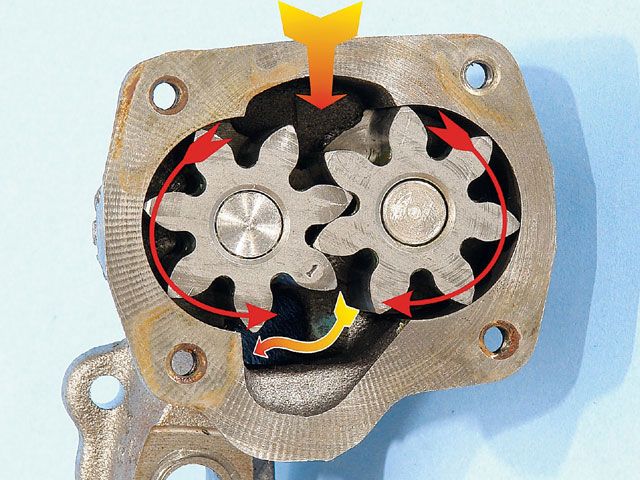

in the factory design the piston on the pressure relief spring opens a direct route less than 1/2" long from one side of the gears to the other, once the pressure on the high pressure side forces the spring under the bye-pass piston back out of the way

the picture posted above, will reduce but not necessarily prevent that issue, as the re-routed line to the oil pump pick-up does little but increase the distance the high pressure oil travels before it returns to the oil pumps low pressure side of the gears while adding a good deal more complexity

I assume your aware there are GEROTOR aftermarket oil pumps available that are more efficient??

in my opinion , and experience and from lots of G.M. engine, race testing.

theres no need for oil pressure to exceed about 65 psi,

it takes power to spin the oil pump against that extra resistance, it induces extra wear on the distributor and cam gears,

and it does nothing to reduce bearing wear or increase cooling on the bearing surfaces,if your engine shows more than about 70 psi, you should open some bearing clearances marginally

(maybe an extra half thousandth on the mains) to increase oil flow volume reaching the main bearings, and use a lower resistance oil pump bye-pass spring.

extra oil flow volume cooling the bearings and valve train will do more for durability than oil pressure exceeding 65-70 psi

http://pitstopusa.com/i-22954300-moroso-bb-chevy-billet-aluminum-pro-gerotor-oil-pump.html

If you're serious about building the ultimate wet sump system, Moroso Racing Oil Pumps are the only way to go! The nation's top engine builders rely on Moroso Oil Pumps because of their superior design and ability to provide a smooth and consistent flow of oil at higher engine speeds. Stock and so-called "race" pumps offered by others are not equipped to handle the higher oil flow at race speeds. As oil velocity increases, other pump designs cavitate and chatter because they just can't handle the extra demand. Moroso Racing Pumps are specifically engineered to accommodate the oil flow required by consistently higher engine speeds. Special anti-cavitation slots, feeder grooves and an enlarged bypass area are machined into the housing to bleed oil back to the inlet side of the pump. These features combine to offer a smooth and consistent flow of oil, which improves the pump's overall performance, extends engine life, and places an even loading on the distributor shaft to eliminate spark scatter. You can't beat a Moroso Oil Pump for precision! These pumps are manufactured using a proprietary casting process that offers superior durability and reliability characteristics. The pump body and cover assembly are manufactured to exact design specifications. Gear and inner rotor shaft assemblies are matched to maintain absolute minimum clearances and provide maximum volumetric efficiency. And each and every Moroso Racing Oil Pump is 100% pressure tested to stringent quality control specifications. When it comes to something as important as oil pressure, insist on Moroso Race Pumps ... there is a difference!

- 6061-T6 billet housing with 5.7 times larger mounting boss area to prevent breaking

- 1.100" Gerotor puts out 25% more volume to maintain ideal oil pressure round after round

- External adjustment allows fine-tuning of oil pump bypass pressure

- Inlet area is increased to prevent cavitation

- Thrust bearing assembly increases housing and gear life due to drive shaft axial forces on the drive gear

- Pump will clear 5.25" stroke with most aluminum rods

- Engineered to fit 8" deep fabricated aluminum oil pans

Moroso BB Chevy Billet Aluminum Pro Gerotor Oil Pump 22167 High-Volume Oil Pump

- Big Block Chevrolet Pit Stop USA offers Moroso BB Chevy Billet Aluminum Pro Gerotor Oil Pump 22167 at low everyday prices. Be sure to check out all of our products from Moroso Performance Products including Moroso Performance Products BB Chevy Oil Pumps.Pit Stop USA offers Moroso BB Chevy Billet Aluminum Pro Gerotor Oil Pump 22167 at low everyday prices. Be sure to check out all our products from Moroso Performance Products including Moroso Performance Products BB Chevy Oil Pumps.Product Description: Oil Pump, Wet Sump, Internal, High Volume, Gerotor, Billet Aluminum, 8" Deep Pan, Big Block Chevy

Chevrolet Performance 14091563

Left (Driver Side) Dipstick Plug

Chevrolet Performance 9421743

Right (Passenger Side) Dipstick Plug

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

http://garage.grumpysperformance.co...l-pumps-pressure-bye-pass-circuit-works.3536/

http://www.milodon.com/oil-system/oil-pumps.asp

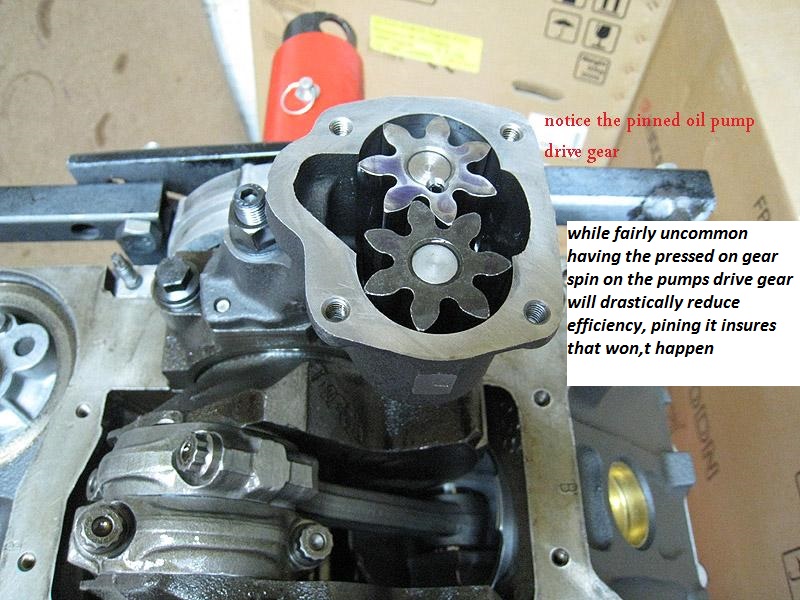

if some internal engine oil control components breaking,in engines, theres a reason,

and its frequently related to either inferior materials being used or component design,

not having the operational stress being induced taken into account in the design phase.

or the components not having been ,manufactured or installed correctly.

example

for awhile SBC oil pumps were breaking after the manufacturer,

tried to save some cash by reducing the thickness of the housing casting ,

this was a really stupid change that cost them a great deal, in customer confidence,

and potential future sales are word, of the defective pump, got around quickly

theres some vibration stress on any oil pump, and the manufacturer rapidly found ,

they were forced to revert to the original older design.

trying to save a few cents per pump so they could undercut the cost,

of the pumps of other manufacturers, and gain an advantage,

cost them rather dearly in sales.

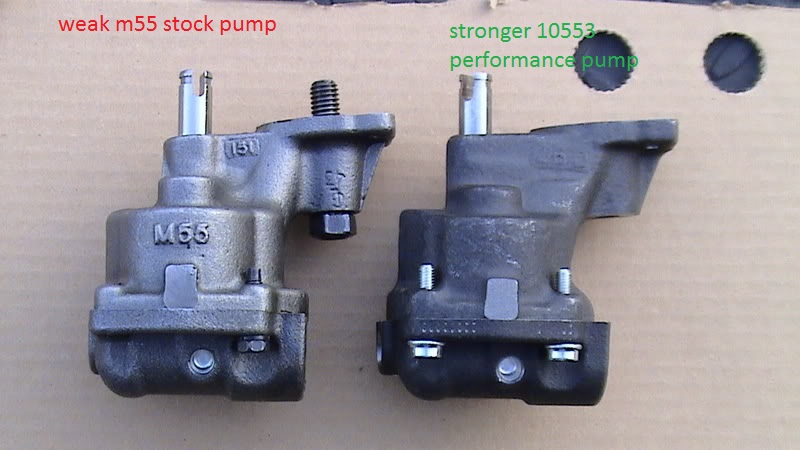

as many of you gentlemen know MELLING CHANGED the casting on their standard M55 high volume oil pumps making them weaker and thinner

Id also point out that, if you properly set up a performance engine with the proper after market oil control components,the stock engine's oil system, can be vastly improved upon, youll want too, open the oil drain holes and use the proper oil pan, windage screen and crank scraper, its virtually impossible , in a well designed engine to run the engine

"long enough to pump all the oil upstairs."

as with a properly designed baffled oil pan, with a carefully fitted and clearanced windage screen and crank scraper, the oil pump simply reaches a flow rate pumping oil out of about 100 or so potential lubricant flow leakage points

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

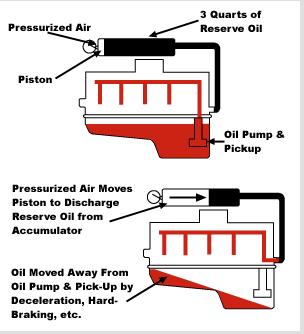

theres zero doubt an accusump oil feed is a good insurance policy to maintain oil pressure at the bearings, but simply having a 7-8 quart baffled oil pan,properly clearanced, windage screen and crank scraper will insure the oil pressure remains consistent , mostly due to the fact that theres always going to be enough oil over the oil pump pick-up, simply because theres really no room to pack most of the available oil volume in the upper engine ,plus the fact that hot oil flows well.

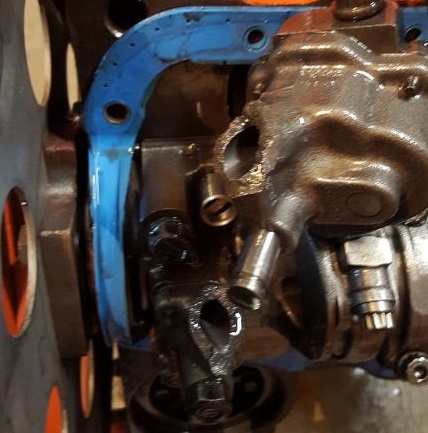

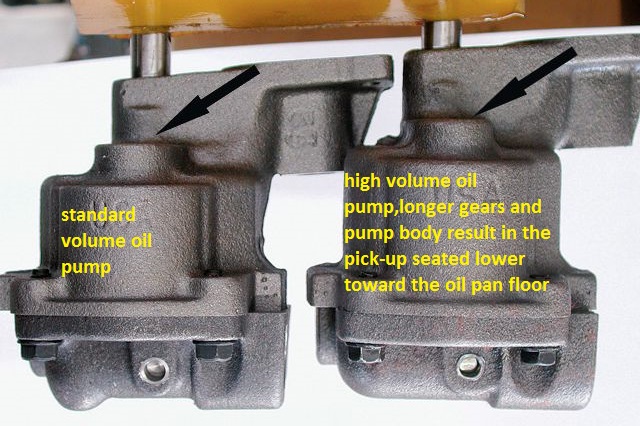

yes Ive seen several cases where guys failed to install the oil pump pick-up at the proper minimum 3/8"-to-1/2" off the oil pan floor clearance,

the result is the pump is starved for oil intake flow.

http://garage.grumpysperformance.co...m-sure-your-convinced-its-the-oil-pump.11085/

http://garage.grumpysperformance.co...m-oil-pump-installed-now-no-oil-pressure.525/

http://garage.grumpysperformance.com/index.php?threads/bbc-oil-pump-in-a-sbc.2598/

OIL PRESSURE read on the oil pressure gauge is a MEASURE of RESISTANCE to oil flow, you can REDUCE the pressure the gauge reads by either increasing the engine clearances or REDUCING the oil viscosity (thickness) so it flows thru the clearances faster with less resistance.(OR INSTALLING A SLIGHTLY WEAKER OIL PUMP BYE_PASS SPRING,that limits the pump pressure before it allows some oil to re-circulate back through the bye-pass valve ,from the high pressure back to the low pressure side of the pump impellers, but only the max pressure you reach is limited by the bye-pass spring,in your oil pressure bye pass circuit and its that spring resistance determines the point where the bye-pass circuit, opens and limits max oil pressure, but the bye-pass circuit has zero to do with anything else, if its functioning correctly,

there are many oil leakage points(100) in a standard Chevy engine.

16 lifter to push rod points

16 push rod to rocker arm points

32 lifter bores 16 x 2 ends

10 main bearing edges

9 cam bearing edges

16 rod bearing edges

2 distributor shaft leaks

1 distributor shaft to shim above the cam gear(some engines that have an oil pressure feed distributor shaft bearing.)

once oil exits the bearings or valve train it flows mostly by gravity back to the oil pan sump, but a properly designed windage screen and crank scraper correctly clearanced allows the spinning crank/rotating assembly to act like a directional pump that drags the vast majority of the oil flow back to the sump, by design.

http://garage.grumpysperformance.com/index.php?threads/whats-a-windage-tray-do.64/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.com/index.php?threads/basic-info-on-your-v8-lube-system.52/