" GRUMPY?? Well, while setting end-gap on a second ring the squaring tool moved, and when I realized it it was too late...

Chart calls for around .016" which is what I got on the inside of the gap, but outside it went all the way to around .021"

I was going to just get a replacement for this one cylinder, but these rings are 1.50 mm thick (made by Mahle) and they don't sell single replacements (the closest thing is a 1/16" ring, but they come to about 1.58 mm thick)

Should I just get a complete set and get rid of the ring or just leave it like that?

Was going to square it but then I will have 1 cylinder with a lot of second ring gap, which don't know how bad it'll be.

My bet is on a complete new set and replace just that ring, but thought I first ask before spending my hard earned cash..

Thanks! "

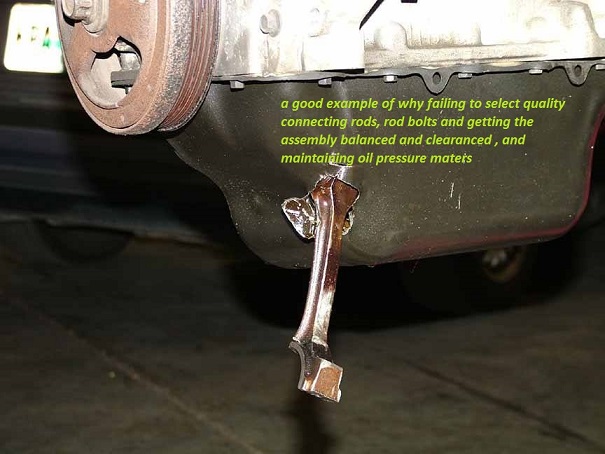

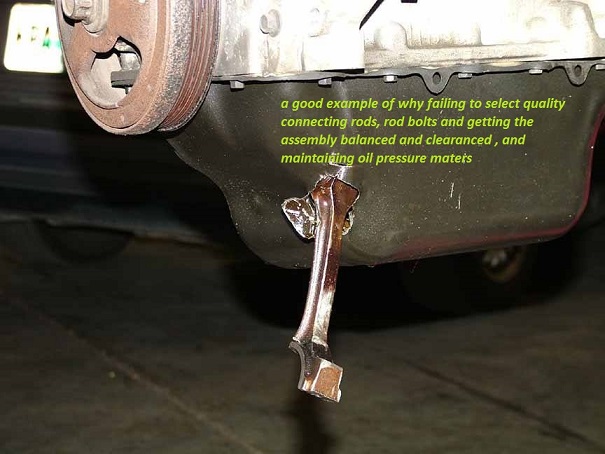

your SBC engine will most likely run just fine with a .021 ring end gap, especially if its only on one cylinder. theres millions of engines running with .021 or larger ring end gaps. in fact Ive seen tests where ring gaps as large as .050 don,t effect your results that much, the result of the larger end gap was only the slight increase in oil burning and a bit more blow bye, when it was tested the result, was power was not effected much at all.

think about it, theres a piston side clearance of maybe .003-.005 and your gaps .021 and at lets say 5500 rpm, that pistons got a power stroke about 46 times a second, how much leakage do you think can get thru a end gap that size, in that , 1/46th of a second, on each power stroke, VS the 25 percent smaller end gap you intended, especially when you consider the exhaust valve opens and drops pressure on the power stroke before its 2/3rds of way down the bore,in many cases and the expansion ratio has reduced pressure significantly before its 30 degrees past TDC.

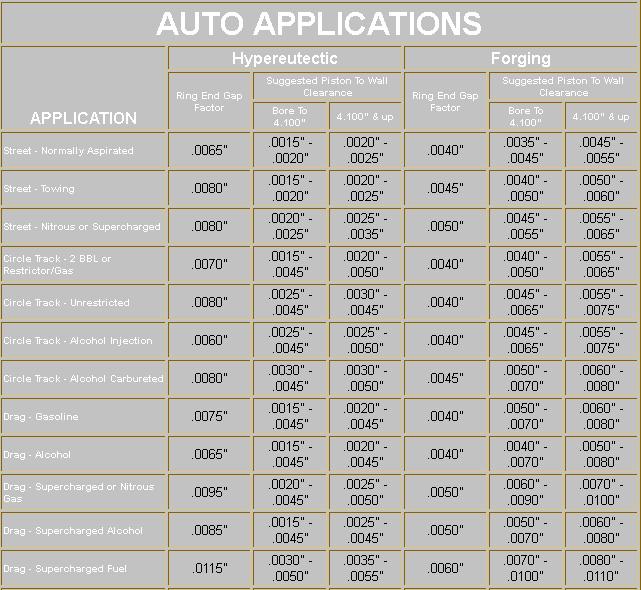

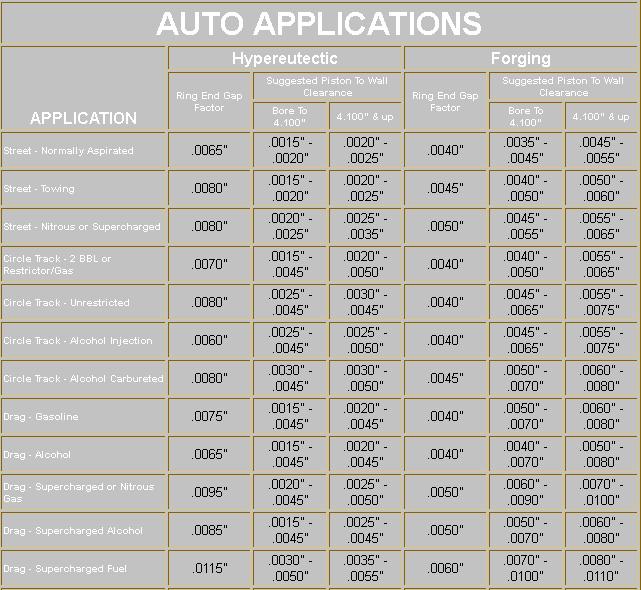

look at the ring gap end chart,I posted (theres others and a ton more info in the links) and decide for yourself

RELATED INFO...look thru the charts and sub links

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=5454

viewtopic.php?f=53&t=2837

https://www.uempistons.com/installation ... lation.pdf

viewtopic.php?f=53&t=2795

Chart calls for around .016" which is what I got on the inside of the gap, but outside it went all the way to around .021"

I was going to just get a replacement for this one cylinder, but these rings are 1.50 mm thick (made by Mahle) and they don't sell single replacements (the closest thing is a 1/16" ring, but they come to about 1.58 mm thick)

Should I just get a complete set and get rid of the ring or just leave it like that?

Was going to square it but then I will have 1 cylinder with a lot of second ring gap, which don't know how bad it'll be.

My bet is on a complete new set and replace just that ring, but thought I first ask before spending my hard earned cash..

Thanks! "

your SBC engine will most likely run just fine with a .021 ring end gap, especially if its only on one cylinder. theres millions of engines running with .021 or larger ring end gaps. in fact Ive seen tests where ring gaps as large as .050 don,t effect your results that much, the result of the larger end gap was only the slight increase in oil burning and a bit more blow bye, when it was tested the result, was power was not effected much at all.

think about it, theres a piston side clearance of maybe .003-.005 and your gaps .021 and at lets say 5500 rpm, that pistons got a power stroke about 46 times a second, how much leakage do you think can get thru a end gap that size, in that , 1/46th of a second, on each power stroke, VS the 25 percent smaller end gap you intended, especially when you consider the exhaust valve opens and drops pressure on the power stroke before its 2/3rds of way down the bore,in many cases and the expansion ratio has reduced pressure significantly before its 30 degrees past TDC.

look at the ring gap end chart,I posted (theres others and a ton more info in the links) and decide for yourself

RELATED INFO...look thru the charts and sub links

viewtopic.php?f=53&t=509

viewtopic.php?f=53&t=3897

viewtopic.php?f=53&t=5454

viewtopic.php?f=53&t=2837

https://www.uempistons.com/installation ... lation.pdf

viewtopic.php?f=53&t=2795

Last edited by a moderator: