the LASH/PRELOAD on a lifter determines several things and one of those is the voluum of oil forced up the pushrod and the valves abilty to bleed off heat to the heads thru the seat contact.

minimizing the preload allows slightly longer seat contact and greater oil flow to the valve train and less likely hood of burnt valves.

the oil trapped under the pushrod seat in the lifter supports the pushrod and can,t be compressed easily , the total distance for preload adjustment most lifter seats have available is in the .060 range, if you minimize the preload the oil reaching the valve train as the seat collapses and forces it up the pushrods increased, as the lobe spins under the lifter, total valve lift may be very slightly effected , but Ive always prefered durrability over trying for the last possiable bit of peak power.

keep in mind , that clearance is set on a relatively cool engine, once you start running it hard the temp. increases rapidly and that lifter and valve train expand due to heat, minimal valve train clearances, and limited oil flow to cool the springs might become a problem, especially when you realise that about 40% of the engine heat comes not from combustion but from the valve train and springs, and friction, valve springs glow red hot and fail in under 5 minutes at 6000rpm with no oil flow to cool them according to SMOKEY YUNICKS TESTING.

you also must keep in mind that as the rpms increase the TIME available for the lifter to bleed off oil under the lifter seat decreases rapidly, resulting in slightly higher effective lift at the valve.

you might want to keep in mind valve preloads usually set while the engines not nearly as hot and the expansion, of the components due too heat is minimal compared to the conditions durring a race, where extra clearances may be necessary in the valve train once everything reaches true opperational heat levels.

http://www.type2.com/library/engineg/hydral2.htm

http://www.ratwell.com/technical/HydraulicLifters.html

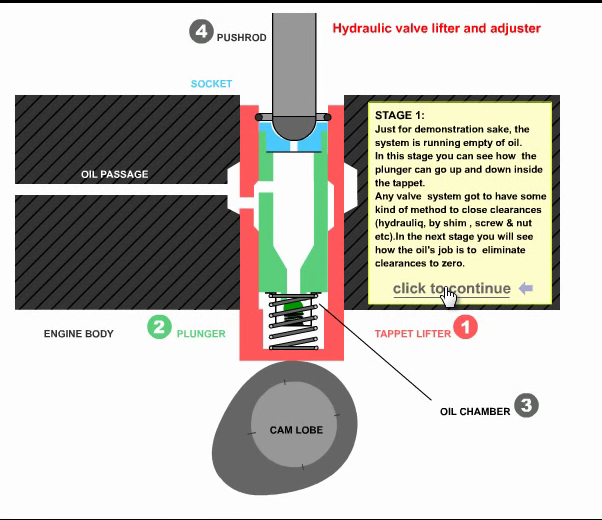

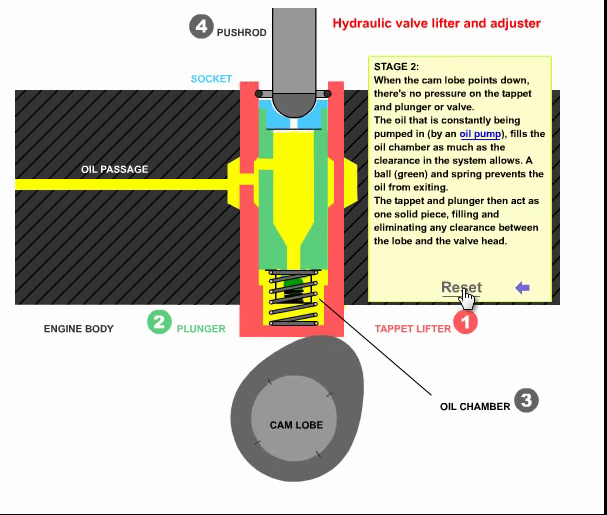

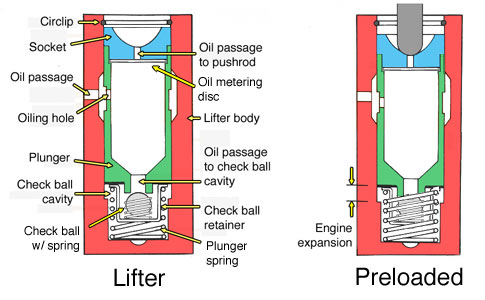

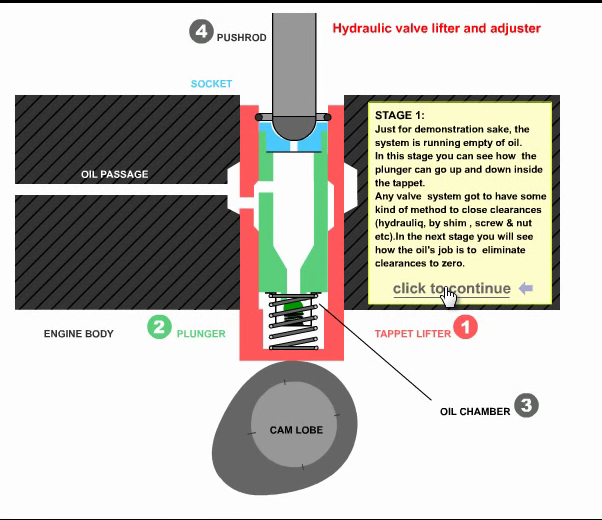

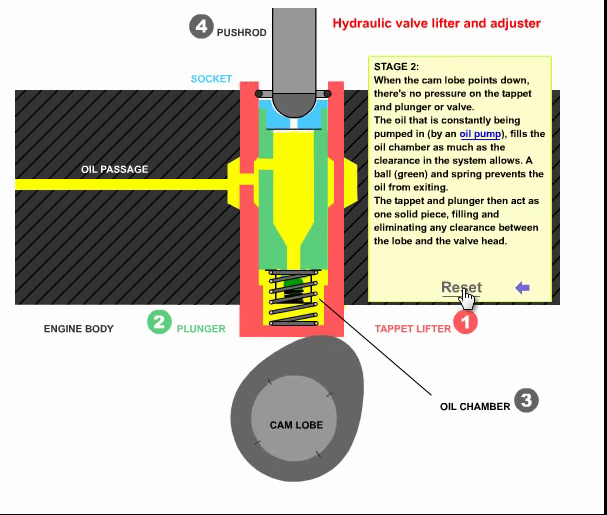

watch this video, it depicts the lifters movement as the cam lobe rotates under its base forcing it up as the lobes ramp, rotates under the lifter base,removing the clearance slack,

as it compresses the valve spring and forces the trapped oil, up the push rod and lifts the valve

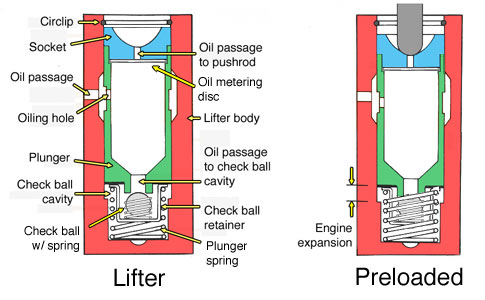

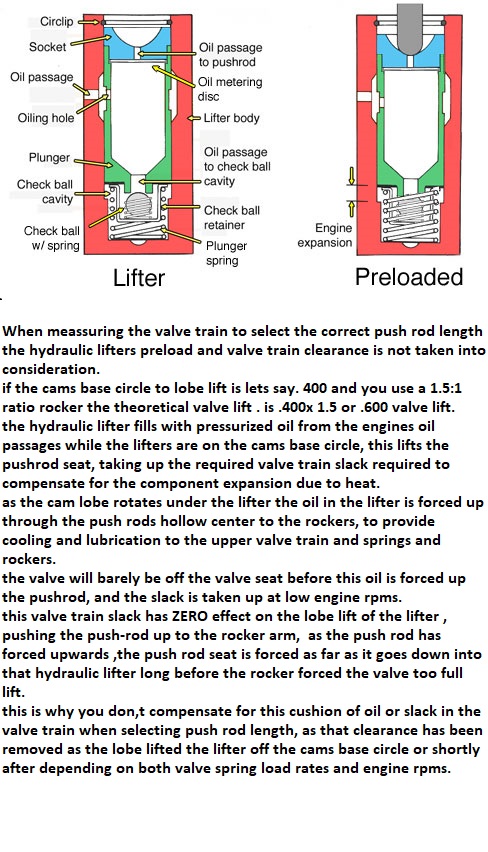

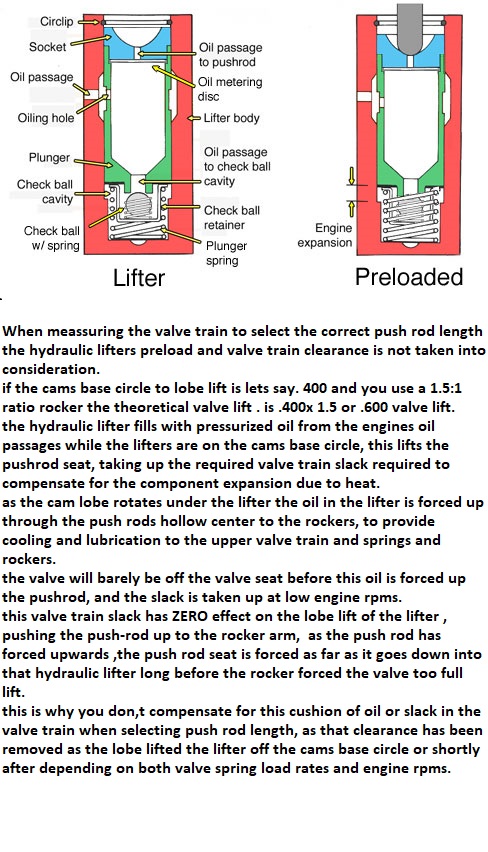

If you are concerned with measuring the clearance in the hydraulic lifter seat when selecting and measuring the correct valve train geometry,

so you can order the correct length push rods...

I don,t think you have the correct idea as to how hydraulic lifters work,

yes it is possible for an engine with hydraulic lifters to be pushed too operate at a high enough rpm that the time required for the lifter seat to fully depress and all the oil too be forced up to the push rod/rockers , to be so short that the lifter pumps up and the valves will have less seat time, ( sometimes one of several factors, like the lifter leaving the cam lobes surface as the inertial loads exceed the valve springs ability to maintain lifter too lobe contact, referred too or contributing to what is commonly referred too as valve float) but that has ZERO to do with selecting push rod length or proper valve train geometry, (remember at 6000 rpm the valve is lifted off its seat 50 times PER SECOND)

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/stock-gm-push-rod-length.3844/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.co...mall-block-chevy-guide-plates.2839/#post-7344

http://garage.grumpysperformance.com/index.php?threads/decent-deal-on-these-push-rod-length-checker-tools.13735/#post-70650

http://garage.grumpysperformance.co...rockers-which-is-best-steel-or-aluminum.3124/

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

http://garage.grumpysperformance.com/index.php?threads/press-in-vs-threaded-rocker-studs.2746/

http://garage.grumpysperformance.co...s-changing-rocker-ratios-and-the-effects.126/

http://garage.grumpysperformance.com/index.php?threads/understanding-valve-spring-bind-height-060-safety-margin.4957/

ALWAYS READ LINKED INFO IN THESE THREADS ON THIS WEB-SITE

have you used one of the push-rod length checker tools?

they might be a good cross check, before you order the push-rods.

it would take a bit more time but it would be cheaper in the long term.

to be sure you got it right than it would be to try to return push-rods

remember the tool works when the lifters on the cams base circle

(yes as simple as they are (PICTURE ABOVE) too use they tend to be rather accurate)

yes I use BOTH the push rod checker tools to get the quick check on length, and the adjustable length push-rods and a marker too method verify the correct length with a cross check by looking at the wear/sweep and location, on the valve tip

http://garage.grumpysperformance.co...sh-rod-length-checker-tools.13735/#post-70650

http://garage.grumpysperformance.co...rdering-correct-custom-length-pushrods.14241/

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

heres a bit of useful related push rod length info (POSTED HERE) youll want to select the correct set or SETS for your shop

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

minimizing the preload allows slightly longer seat contact and greater oil flow to the valve train and less likely hood of burnt valves.

the oil trapped under the pushrod seat in the lifter supports the pushrod and can,t be compressed easily , the total distance for preload adjustment most lifter seats have available is in the .060 range, if you minimize the preload the oil reaching the valve train as the seat collapses and forces it up the pushrods increased, as the lobe spins under the lifter, total valve lift may be very slightly effected , but Ive always prefered durrability over trying for the last possiable bit of peak power.

keep in mind , that clearance is set on a relatively cool engine, once you start running it hard the temp. increases rapidly and that lifter and valve train expand due to heat, minimal valve train clearances, and limited oil flow to cool the springs might become a problem, especially when you realise that about 40% of the engine heat comes not from combustion but from the valve train and springs, and friction, valve springs glow red hot and fail in under 5 minutes at 6000rpm with no oil flow to cool them according to SMOKEY YUNICKS TESTING.

you also must keep in mind that as the rpms increase the TIME available for the lifter to bleed off oil under the lifter seat decreases rapidly, resulting in slightly higher effective lift at the valve.

you might want to keep in mind valve preloads usually set while the engines not nearly as hot and the expansion, of the components due too heat is minimal compared to the conditions durring a race, where extra clearances may be necessary in the valve train once everything reaches true opperational heat levels.

http://www.type2.com/library/engineg/hydral2.htm

http://www.ratwell.com/technical/HydraulicLifters.html

watch this video, it depicts the lifters movement as the cam lobe rotates under its base forcing it up as the lobes ramp, rotates under the lifter base,removing the clearance slack,

as it compresses the valve spring and forces the trapped oil, up the push rod and lifts the valve

so you can order the correct length push rods...

I don,t think you have the correct idea as to how hydraulic lifters work,

yes it is possible for an engine with hydraulic lifters to be pushed too operate at a high enough rpm that the time required for the lifter seat to fully depress and all the oil too be forced up to the push rod/rockers , to be so short that the lifter pumps up and the valves will have less seat time, ( sometimes one of several factors, like the lifter leaving the cam lobes surface as the inertial loads exceed the valve springs ability to maintain lifter too lobe contact, referred too or contributing to what is commonly referred too as valve float) but that has ZERO to do with selecting push rod length or proper valve train geometry, (remember at 6000 rpm the valve is lifted off its seat 50 times PER SECOND)

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

Proform Pushrod Length Checkers 66806 BBC 7/16" rocker studs

http://garage.grumpysperformance.com/index.php?threads/valve-train-clearances-and-problems.528/

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/stock-gm-push-rod-length.3844/

http://garage.grumpysperformance.com/index.php?threads/rocker-push-rod-wear-issues.9815/

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.co...mall-block-chevy-guide-plates.2839/#post-7344

http://garage.grumpysperformance.com/index.php?threads/decent-deal-on-these-push-rod-length-checker-tools.13735/#post-70650

http://garage.grumpysperformance.co...rockers-which-is-best-steel-or-aluminum.3124/

http://garage.grumpysperformance.com/index.php?threads/valve-springs.9613/

http://garage.grumpysperformance.co...lve-springs-loads-and-installed-height.10709/

http://garage.grumpysperformance.com/index.php?threads/press-in-vs-threaded-rocker-studs.2746/

http://garage.grumpysperformance.co...s-changing-rocker-ratios-and-the-effects.126/

http://garage.grumpysperformance.com/index.php?threads/understanding-valve-spring-bind-height-060-safety-margin.4957/

ALWAYS READ LINKED INFO IN THESE THREADS ON THIS WEB-SITE

have you used one of the push-rod length checker tools?

they might be a good cross check, before you order the push-rods.

it would take a bit more time but it would be cheaper in the long term.

to be sure you got it right than it would be to try to return push-rods

remember the tool works when the lifters on the cams base circle

(yes as simple as they are (PICTURE ABOVE) too use they tend to be rather accurate)

yes I use BOTH the push rod checker tools to get the quick check on length, and the adjustable length push-rods and a marker too method verify the correct length with a cross check by looking at the wear/sweep and location, on the valve tip

http://garage.grumpysperformance.co...sh-rod-length-checker-tools.13735/#post-70650

http://garage.grumpysperformance.co...rdering-correct-custom-length-pushrods.14241/

http://www.summitracing.com/search/...d-length-checkers?autoview=SKU&ibanner=SREPD5

Proform Pushrod Length Checkers 66789 SBC 3/8" rocker studs

Proform Pushrod Length Checkers 66790 SBC 7/16" rocker studs

heres a bit of useful related push rod length info (POSTED HERE) youll want to select the correct set or SETS for your shop

Big Block Chevy, Standard Length Big Block Intake 3/8" / .080" 8.275"

295-7941-8 Big Block Chevy, Standard Length Big Block Exhaust 3/8" / .080" 9.250"

295-7969-8 Big Block Chevy, Standard Big Block +.100" Long Intake 3/8" / .080" 8.375"

295-7979-8 Big Block Chevy, Standard Big Block +.100" Long Exhaust 3/8" / .080" 9.350"

295-7951-8 Big Block Chevy, Standard Length Big Block Tall Deck Intake 3/8" / .080" 8.675"

295-7961-8 Big Block Chevy, Standard Length Big Block Tall Deck Exhaust 3/8" / .080" 9.650"

295-7800 V8 396-454 Retro Fit Pushrod Set, Intake & Exhaust, 1965-Present

3/8" / .080"

3/8" / .080" 7.725 Int.

8.675 Exh

295-7913-16 Small Block Chevy, Standard Length Small Block Chevy 3/8" / .080" 7.800"

295-7984-16 Small Block Chevy, +.100" Long 3/8" / .080" 7.900"

295-7934-16 Big Block Ford, Standard Length Ford `72-'78 429-460 3/8" / .080" 8.550"

295-7951-16 Big Block Ford, Standard Length Ford `69-'71 429-460 3/8" / .080" 8.675"

295-7582-16 Oldsmobile, Std Length 455 5/16" 9.550"

Last edited by a moderator: