Ive always been rather amazed at the number of guys that want to build a 600hp-800hp big block or turbo small block engine, who tend to think the stock fuel lines, fuel pump and fuel tank can keep up with the new higher flow rate demands required.

OR guys that see the need for larger fuel lines and fuel pump but connect those components to the stock un,modified fuel tank and internal fuel pick-up.

the result I usually see, with guys who do that is a car that runs fairly decent until about the top end of second gear and then leans out, because the fuel system can,t come close to filling the new higher flow requirements.

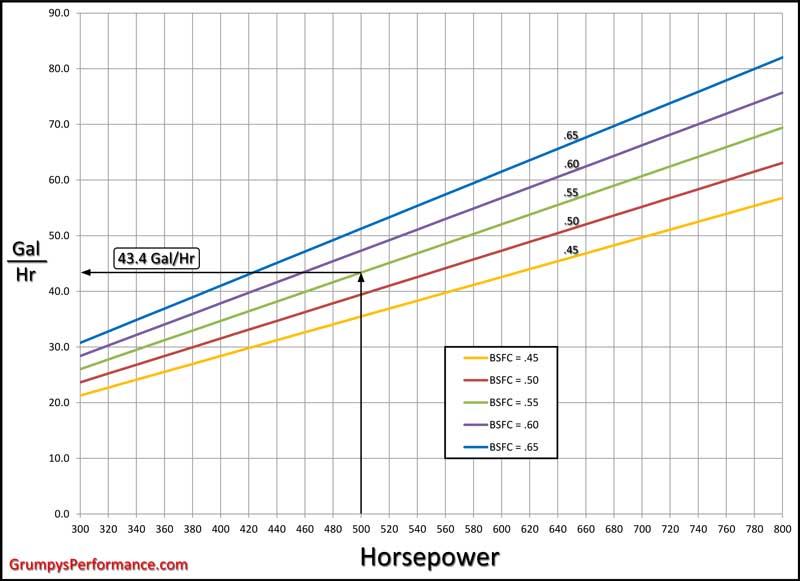

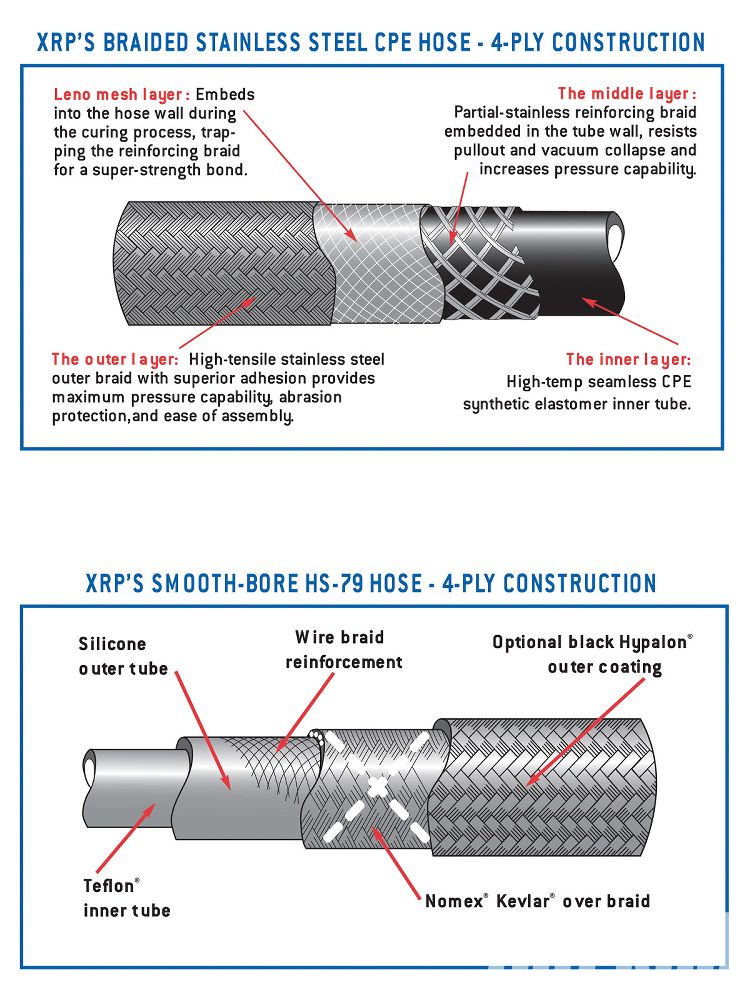

Most electric fuel pumps PUSH fuel fairly well, but will stall or not feed fuel easily if even slightly restricted on the intake port side, at some point (usually at or near 500- 550 hp) the stock fuel lines , even with a new high pressure fuel pump and larger fuel lines just won,t work if you retain the stock tank and fuel tank pick-up. at some point your forced to upgrade from the stock fuel lines that rarely exceed 3/8" to performance application 1/2" or AN#8 fuel lines OR larger and compatible tank fuel pump and fuel lines, that should support up to about 800 plus hp, over that you might need AN#10 lines and components.

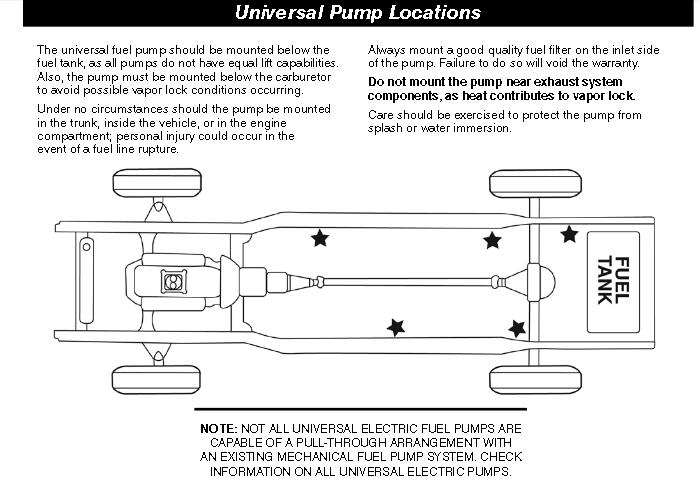

in tank electric fuel pumps REQUIRE fuel sloshing over the pump to keep it cool, obviously the ideal pump installed location will require a lower sump, to keep the pump submerged in a partly filled tank, EXTERNAL electric fuel pumps will occasionally fail to prime if the pump is not mounted lower than the tank floor pick-up height.

RELATED INFO

viewtopic.php?f=32&t=33&p=41#p41

http://www.carterfueldelivery.com/fuelp ... P_Inst.pdf

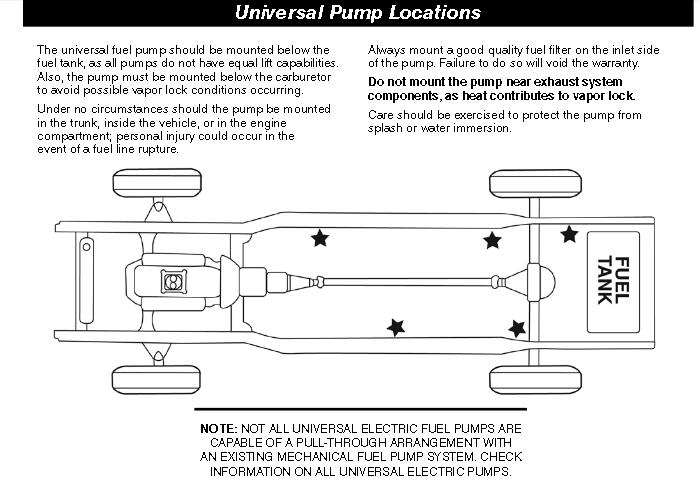

external electric fuel pumps should generally be located as close to the fuel tank as practical to minimize restriction

,and inside the frame rails, to provide some extra protection in an accident,away from exhaust pipe heat,or moving components,

and as low as possible , to ease the pump maintaining its priming

http://www.kartek.com/Product/FuelSyste ... ickup.html

http://www.racerpartswholesale.com/prod ... ick_Up_Kit

http://www.racerpartswholesale.com/cate ... Safe_Cells

http://www.racerpartswholesale.com/prod ... And_Wiring

http://www.summitracing.com/parts/sum-290108/overview/

http://www.summitracing.com/parts/rci-2 ... dia/images

http://www.summitracing.com/parts/rci-2171a/overview/

http://www.summitracing.com/parts/rci-1160ds/overview/

http://www.summitracing.com/parts/sum-2 ... /overview/

READ THIS

http://autolabscopediagnostics.com/fuelpump.htm

OR guys that see the need for larger fuel lines and fuel pump but connect those components to the stock un,modified fuel tank and internal fuel pick-up.

the result I usually see, with guys who do that is a car that runs fairly decent until about the top end of second gear and then leans out, because the fuel system can,t come close to filling the new higher flow requirements.

Most electric fuel pumps PUSH fuel fairly well, but will stall or not feed fuel easily if even slightly restricted on the intake port side, at some point (usually at or near 500- 550 hp) the stock fuel lines , even with a new high pressure fuel pump and larger fuel lines just won,t work if you retain the stock tank and fuel tank pick-up. at some point your forced to upgrade from the stock fuel lines that rarely exceed 3/8" to performance application 1/2" or AN#8 fuel lines OR larger and compatible tank fuel pump and fuel lines, that should support up to about 800 plus hp, over that you might need AN#10 lines and components.

in tank electric fuel pumps REQUIRE fuel sloshing over the pump to keep it cool, obviously the ideal pump installed location will require a lower sump, to keep the pump submerged in a partly filled tank, EXTERNAL electric fuel pumps will occasionally fail to prime if the pump is not mounted lower than the tank floor pick-up height.

RELATED INFO

viewtopic.php?f=32&t=33&p=41#p41

http://www.carterfueldelivery.com/fuelp ... P_Inst.pdf

external electric fuel pumps should generally be located as close to the fuel tank as practical to minimize restriction

,and inside the frame rails, to provide some extra protection in an accident,away from exhaust pipe heat,or moving components,

and as low as possible , to ease the pump maintaining its priming

http://www.kartek.com/Product/FuelSyste ... ickup.html

http://www.racerpartswholesale.com/prod ... ick_Up_Kit

http://www.racerpartswholesale.com/cate ... Safe_Cells

http://www.racerpartswholesale.com/prod ... And_Wiring

http://www.summitracing.com/parts/sum-290108/overview/

http://www.summitracing.com/parts/rci-2 ... dia/images

http://www.summitracing.com/parts/rci-2171a/overview/

http://www.summitracing.com/parts/rci-1160ds/overview/

http://www.summitracing.com/parts/sum-2 ... /overview/

READ THIS

http://autolabscopediagnostics.com/fuelpump.htm

Last edited by a moderator: