if theres a significant temp difference between the inside and outside of your shop, whether your cooling or heating the shop having UN-insulated or open shop garage doors provides a huge temp transfer area

now most of you probably require heat to work in your shops at least part of the year, in my case that's probably for only one-two weeks as IM in Florida, but in any case the garage door is a potential area that allows a great deal of heat transfer, in my case I try to keep the doors shut and several large fans running to duct heat up and out of the shop providing a cooler work environment.

Ive got a 2600sq foot shop with two roof exhaust fans both rated at 2800 cubic feet per minute pulling heat out of the shop attic and (21) 60" industrial shop fans keeping the shop air moving.

on hot days that's usually adequate to make it a livable temp in the shade of the shop without air conditioning if the doors remain closed, on cold days I use a 42000 btw kerosene shop heater that does a surprisingly effective job of removing the chill on the rare cold days,

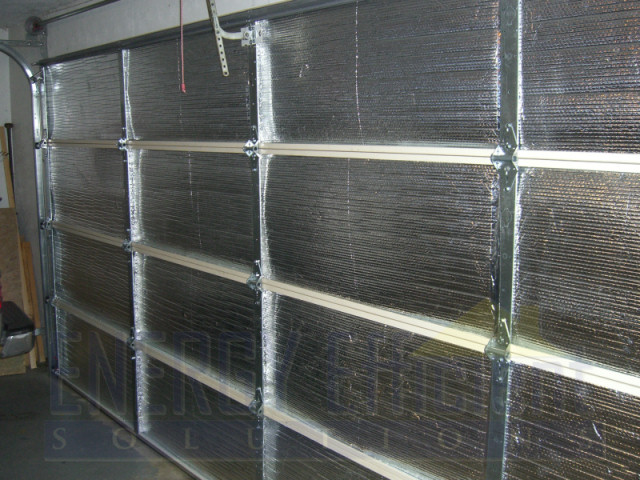

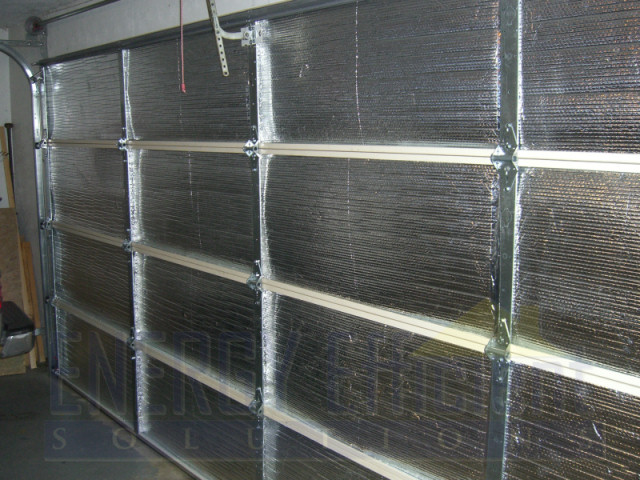

ABOVE is a typical UN BRACED NON hurricane rated door with an insulation kit

All radiant barriers have at least one reflective (or low emissivity)

surface, usually a sheet or coating of aluminum. Some radiant barriers

have a reflective surface on both sides. Both types work about equally

well, but if a one-sided radiant barrier is used, the reflective

surface must face the open air space. For example, if a one-sided

radiant barrier is laid on top of the insulation with the reflective

side facing down and touching the insulation, the radiant barrier will

lose most of its effectiveness in reducing heating and cooling loads."

The foil radiant barrier requires an air space - it's not supposed to

touch anything. If it is touching the back of the wall covering it

loses some of its effectiveness.

The foil also acts as a vapor barrier, which may or may not be

necessary depending on what type of rigid foam insulation it's on.

http://www.energyefficientsolutions.com ... oorkit.asp

http://www.diynetwork.com/how-to/how-to ... index.html

http://www.reflectixinc.com/basepage.asp?PageIndex=547

now most of you probably require heat to work in your shops at least part of the year, in my case that's probably for only one-two weeks as IM in Florida, but in any case the garage door is a potential area that allows a great deal of heat transfer, in my case I try to keep the doors shut and several large fans running to duct heat up and out of the shop providing a cooler work environment.

Ive got a 2600sq foot shop with two roof exhaust fans both rated at 2800 cubic feet per minute pulling heat out of the shop attic and (21) 60" industrial shop fans keeping the shop air moving.

on hot days that's usually adequate to make it a livable temp in the shade of the shop without air conditioning if the doors remain closed, on cold days I use a 42000 btw kerosene shop heater that does a surprisingly effective job of removing the chill on the rare cold days,

ABOVE is a typical UN BRACED NON hurricane rated door with an insulation kit

All radiant barriers have at least one reflective (or low emissivity)

surface, usually a sheet or coating of aluminum. Some radiant barriers

have a reflective surface on both sides. Both types work about equally

well, but if a one-sided radiant barrier is used, the reflective

surface must face the open air space. For example, if a one-sided

radiant barrier is laid on top of the insulation with the reflective

side facing down and touching the insulation, the radiant barrier will

lose most of its effectiveness in reducing heating and cooling loads."

The foil radiant barrier requires an air space - it's not supposed to

touch anything. If it is touching the back of the wall covering it

loses some of its effectiveness.

The foil also acts as a vapor barrier, which may or may not be

necessary depending on what type of rigid foam insulation it's on.

http://www.energyefficientsolutions.com ... oorkit.asp

http://www.diynetwork.com/how-to/how-to ... index.html

http://www.reflectixinc.com/basepage.asp?PageIndex=547