Shopping for Heads (and using posted & advertized flow numbers as a guide can be misleading)

I found this (QUOTE BELOW) posted on a different site and while I agree with some statements and don,t agree with others its well worth reading thru for a different perspective, if you read thru the posted info I will agree that a great many cylinder heads get selected on the basis of posted flow numbers or price alone, and the fact is that the cam timing, intake design,operational rpm band, displacement ,compression ratio and exhaust scavenging all have a pronounced effect on how well the fuel and air flow thru a cylinder head port, and you don,t always get the best horse power by selecting the head with the highest posted and advertized flow numbers.

I'd also point out that the exhaust gases are physically forced out by the piston on the exhaust stroke and given a huge help in exiting the cylinder if you have a properly designed header that scavenges the cylinder,and that rapidly exiting exhaust gas does help to draw in the next intake charge PROVIDED the cam timing and exhaust header are properly matched, and since flow benches measure flow at a static valve lift and engine have a piston rotating at maybe 6000rpm and valve that opens and closes 55 times PER SECOND and theres no exhaust scavenging ,while the heads tested,theres no way in hell that a flow bench accurately duplicates flow conditions in a running engine

http://www.strokerengine.com/SBCHeadsFlow.html

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/#post-49711

[quote="jsup"]

Shopping for Heads

As I started to dig down and learn more, I found out that a lot of marketing hype was just that, hype.

For guys doing builds, $1500+ is a lot of money, so I put together the facts, as I found them, and had them verified my findings through six independent, qualified sources. One source is an areonautical engineer who worked for a major military aircraft manufacturer and designed fighter jets. He decided he wanted to build race engines, so he now makes his living building sprint car, drag, street motors. He's done 100s of motors and has over a decade of experience. That is typical of the quality of my research.

This paper was the genesis of getting me kicked off another forum, as a forum sponsor did not like the fact that my findings were in conflict with his marketing. I hope people here can read it for what it is, a sober assessment of some of what goes into head design and items for consideration when choosing a head.

All my information again, has been vetted by a 7th source, and still withstands the test of facts. I am not saying what I write is gospel, but it's one man's view. I spent over a moth of research and I hope that my countless hours of work prove useful for someone.

I am not an engineer, I am not a tech. I am a sales/marketing guy for a living, so I relied on people who are techs and engineers for my information.

I have studied the subject in quite some depth, for quite some time. I did not rely on marketing brochures or manufacturer’s claims. I have spent the last month talking to Engineers, FOUR of them. One of which is a close friend who has 7 Engineering degrees from Steven’s Institute here in Jersey. Oh, did I mention he even carries a Masters in Engineering? But wtf does he know? Happens to be he’s an avid racer and part time engine builder. Not a professional builder, but he puts his own engines together. He is one of the few people who ever finished all seven disciplines of engineering in the history of Stevens, not a stupid man for sure.

Two engineers who have offered their expertise on fluid dynamics and have verified this information independently of each other. The first has 25 years of fluid dynamics experience working as an engineer designing shocks. The second, is an aeronautical engineer and engine builder. The last is an engineer who’s job it is to design heads, who is not a forum member. Also, I sat with two engine builders who both have a long history and great reputation. I challenge ANYONE to dismiss the DECADES of expertise I have assembled prior to putting out this information and request please ensure your expertise can hold a candle to what I have addressed in the aforementioned paragraph.

Although I am no technical expert, being smarter than your average bar stool I have learned the following. I have had each of them review this information for accuracy before posting, and they have blessed it as completely accurate.

First of all, I anticipate you're going to hear a lot of noise about this and that. Typically you're going to hear about flow numbers and port size. You are going to be told that the ideal head is the one with the biggest flow and the smallest port. Like all urban legends, there is some truth to that but also like urban legends, has little basis in fact. Port size and flow are not the “be all to end all” in head selection.

You're going to hear a lot of noise from the self appointed "experts", many who probably need help tying their shoes. Their expertise will be based on sweeping the floors at a high performance shop in the middle of nowhere while some have even read a brochure or two. You will find even more who went to the track once or twice, with many who know a guy who did something a few years back, or have actually ridden in really fast cars. So I recommend you consider the sources relative expertise as it relates to the subject matter at hand when weighing such advice. I am no such technical expert. I'm just a guy who likes to learn about this stuff, so I go to the experts in the field and ask the questions, and listen to the answers, and learn what I can when I can based on my capacity.

Marketing brochures have little value. For example, I wanted to know about disc injectors so I called Lucas and talked directly to the engineer who designed them, for over an hour....now, that does not make me an expert, however, I try to relay the information I gained since we all can't talk to the guy this is the best one can do in this situation.

And finally, never trust an opinion from someone who has a vested interest in the outcome. Manufacturer's lie to sell product, simple. If a claim seems a little preposterous, it probably is. You will not see a 40HP difference from one manufacturer's head to another if compared to like products in respective product lines.

I find value in engineering. I find little value in people going through a catalog and picking out the coolest most expensive parts in the consumer realm, screwing them together and calling themselves experts. I look to racing as the arbiter of quality, process, and results. BILLIONS of dollars a year is spent on R&D in racing circles so it's a good place to reference, even for a street build...An example I like to use is kinda like a guy bragging about his Sony receiver to a guy who has a wall full of tube McIntoch equipment. Two different worlds and two different levels of equipment, but doesn't mean you can't learn from the higher end, when building the lower end.

Bottom line I have put considerable time, effort, and energy into developing this information , and I would appreciate it if it is read and digested and people don’t start spouting off about flow numbers. I hope that we all can learn something from my research and the great amount of time I spent. I will recite just the facts as the experts have presented them. I challenge ANYONE to find fault with the facts I will present going forward. I recommend you call someone, if you have trouble with the big words and intangible concepts.

But I digress, so let's cut through the crap I expect you're going to hear:

1. It's all about flow....true and false...

Looking at cylinder head flow on a flow bench represents simply how restrictive the intake tract is, that’s it, period. It is one metric that contributes to cylinder head performance, there are others, arguably, more important. In other words, are you breathing through a straw or a garden hose… Unfortunately for everyone that develops engine combinations; air isn’t simply sucked through the intake tract as a constant stream. Elements such as intake valve closing, pressure bleeding through the ever so slightly opened intake valve cause what is commonly referred to as reversion. When was the last time you ever heard that mentioned here? This is important because it demonstrates that the one dimensional view of a dry flow bench does not take into consideration true operational environments.

The “reversion” is a pulse of pressure that is part of the longitudinal wave (look it up) traveling back up the intake track. You see it push back through the carburetor when the timing of the event, actually the tuning of the intake tract, is off and the pulse is passing too far up the intake tract. Who hasn’t seen fuel spouting out of the intake once or twice? What do you think that does to engine performance? Common sense dictates that this is not a good situation, so port design matched to intake design is of consummate importance, above and beyond flow numbers.

Another important aspect is that air cannot compress at any velocity we will find inside an intake tract so it must speed up or slow down with changes in cross sectional area. (again look it up) This represents the biggest shortcoming of the DRY flow bench. The bench does not measure velocity, nor does it attempt to predict or model any of the increases or decreases encountered throughout the intake tract and how they are affecting flow. This means that all too often an intake tract is ineffective at controlling intake velocities throughout the entire operating range for the particular engine, throughout the entire intake tract (both are a big issue). In other words, FLOW NUMBERS DON’T TELL THE WHOLE STORY ON A ANY FLOW BENCH! In order for air to compress to a meaningful level, and achieve above 100% VE, air speed of .6 mach is necessary, that air speed is rarely reached inside an engine.

This also leads to problems when working with the wet flow development. The concept of wet flow makes sense to most people; fuel is atomized into the intake tract and needs to stay evenly distributed all the way into the combustion chamber. Many experienced designers have found the all too common problem associated with converting a design from gasoline to alcohol. Since we have different mixtures associated with the fuels the density and overall saturation changes as well. So gas burns differently than alcohol, and you have to have ore of one than the other in and of itself is not really earth shattering, HOWEVER, this serves to demonstrate that it’s about DESIGN not just flow. Another example where flow numbers don’t matter. With the wet flow bench one can at least attempt to identify and monitor problematic areas of the intake tract (designers whish there were even more robust methods)

The advantage to wet flow is that engineers can build a head on paper, bolt it to a wet flow bench, and see if reality and paper line up. If they don't, they can adjust and re-try. This significantly accelerates R&D as it is a true representation of what happens in the operational environment under operational conditions. Read as, we can see the flow, but not at 6000 rpms, so although better than dry flow, not perfect.

The dry flow method of development is what I call hack and guess . What people will do is take a set of heads, and hand port them. Each cyl will be made slightly different than the other, then the head is put on a flow bench. The cyl that has the highest number is the winner. Then you take another set and do the same thing.... and again, until you're convinced you have the best number you can get. This does not tell you anything about the quality of the flow, just the quantity. Also, does nothing to aide in the design of the flow, simply modifications after the fact of design.

An even bigger problem is once airflow becomes a problem upstream the entire tract is not designed in an effort to correct this, it simply stays somewhat messed up and depending on how the rest of the tract is design can potentially get worse as it flows, in other words, it’s a mess. The quality of the airflow is important, not only the quantity. What this results in is that irregular airflow causes problems with the mixture and subsequently, causes problems with the proper air/fuel mixture getting into the cylinder. If you talk to people who design on wet flow benches, they will tell you that yes, their dry flow numbers on paper are not as good as some other manufactures. HOWEVER, it is their position that they can suck more fuel into the cylinder more cleanly and efficiently based on their designs (the resulting changes to promote better flow characteristics on the wet bench will often lower flow numbers on the dry bench slightly, negating the port size/CFM flow argument TOTALLY). They will also tell you that dry flow numbers are utter bullshit and have no indication of the actual performance of a head outside of the one metric that a dry bench measures. That is their position, and it makes total sense.

Take a time out, go get a drink, and come back for the rest. It is far easier to parrot marketing crap than to think deeply as to what goes into the development of a head and those aspects which embody making power. I know this can be tiresome and trying, but I did the work dammit, and you’re going to read it.

2. Smaller port size, the better for same flow

Looking above we see that there is a great deal of effort put into not only how much air could be pulled through the port, but mostly, how it will get through the port, that’s what is really important, getting air into the engine during actual operation effectively and efficiently, it’s not all about VOLUME, it’s about QUALITY. You must always remember that a flow bench is only measuring how easily air can be pulled into the cylinder, not how much fuel is in that stream or the QUALITY of the flow when operation is actually taking place. This means that when comparing cylinder head sizes the most important aspect as the SHAPE of the port and how that shape relates when viewing flow all the way to the combustion chamber. Airflow must be controlled, and hence the shape and measurements of the port are far more important that just looking at flow versus runner size. In other words DRY FLOW BENCHES ARE USELESS IN HEAD DESIGN AND FLOW VS. RUNNER SIZE IS A MYTH.

Again; a flow bench does not measure how much air will be pulled through the port during operation or the quality of delivery of that air, it measures the most simple of measurements, how easily it can be pulled though in a vacuum. Which tells you nothing about head performance.

When looking to design a port design a big consideration is to see what the airflow demands will be; they also must look to what type and how much fuel will be induced into the mix, what RPM the engine will be operating at and lastly, must look past the port into the combustion chamber and into the intake manifold. Again, a head with lower flow bench numbers which produces better charge delivery (through cleaner airflow and physics) and does so throughout the operating range of the engine, is a better, more efficient head that creates more power. Despite the mantra we hear here about efficiency being measured by some made up formula of port size vs. flow numbers, that is not the case in true engineering, or the laws of physics. It is simplistic marketing hype for the simpleton masses.

Significant hp can be gained or lost by port design regardless of the airflow number changes. GASP! A cutting edge cylinder head not only has low restriction and a proper shape for tuning purposes it also has to control velocity along with cutting back on irregular flow (turbulence). Now, a combustion chamber can promote flow or hinder it, it can also promote proper filling and flame travel (often trade offs); how a cylinder is filled is as important as how much of it is filled; all of the above have to balanced throughout the design process as there is no end all be all design that contains the best of every aspect. Flame travel, ever hear flame travel mentioned here? I didn’t think so. No one here wants to think real hard about stuff, it’s easier to spew meaningless numbers.

Another very complicated aspect of how the engine makes its power, valve and spark plug placement and combustion chamber shape have to consider this as well as how much air it can pass! To sum up, without the benefit of a wet flow bench, you would never be certain as to how the design works (and even the wet flow bench leaves something to be desired amongst designers but hey it’s a step in the right direction that measures additional variables). Now, that’s not to say you can’t get lucky by coping someone else’s design, or through trial and error like many speed shops, however, there is no science behind guessing on a dry flow bench (just what worked well in the past…). It’s brute force vs. elegant design.

3. Exhaust flow has real meaning.

This is one that every professional I talk outright laughs at; the idea that a cylinder head has to flow a ton on the exhaust side to make good power. When I ask this question I usually get a response like “a 900hp race engine has an exhaust port that flows 250cfm, so why would you feel that a street engine needs one to support 500-600hp?”. Does sound ridiculous on the face of it doesn’t it?

Think about this in terms of airflow demand just as we would the intake side. Again, the shape and tuning of the exhaust is what pulls the last bit of exhaust out and first bit of intake charge in, not the flow number. In other words, in the absence of real design work being done, go for brute force, or big numbers. This is not a design, this is a guess. Think of a siphon, if you’re simply letting water run out of a hose, vs, a siphon sucking it through, that’s what port design and wet flow (on the intake side) will do for you and that is why exhaust flow numbers are meaningless. That is why we put X pipes in our cars. Isn’t it? If you don’t subscribe to the above, I will expect we should all be pulling out our X pipes tomorrow..

Therefore, a few engine builders have expressed that they do not feel that restriction in the exhaust port is anything to really look at, the flow bench number, and it has no value. To them it’s all about tuning that tract to do the above. Many will cite how unimportant cylinder head flow numbers become when a supercharger is added to the intake side as some of the reasoning they feel that exhaust port flow numbers are not the hot ticket. So essentially, this exhaust flow thing you’re going to hear is utter nonsense perpetuated by the ignorant, ill informed and uneducated.

I have also learned other things about engine design and they are also important, as they relate to head design. There are aspects of engine design such as:

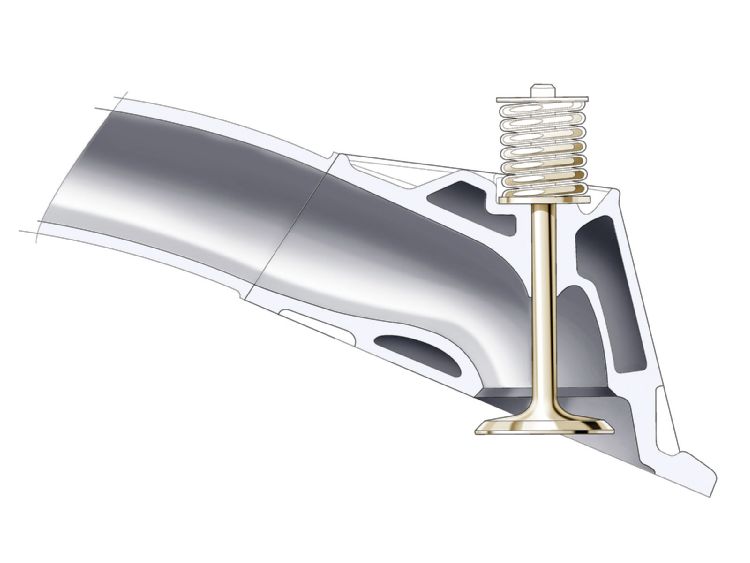

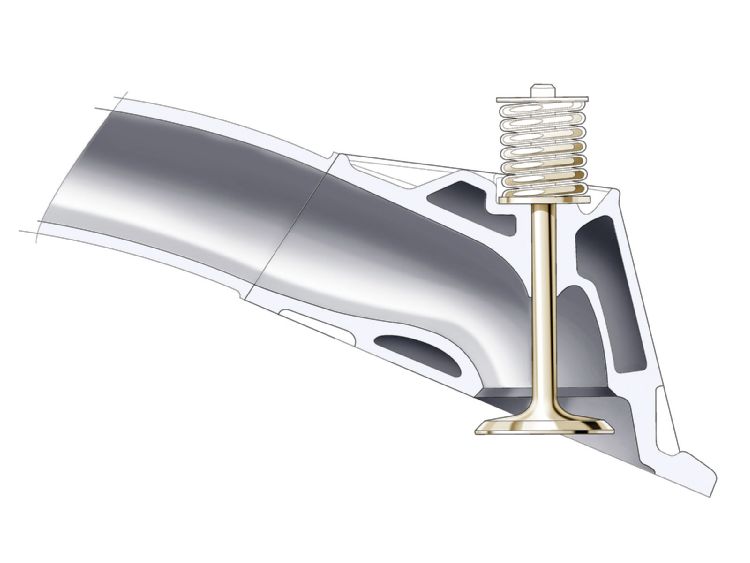

A modern camshaft like one produced by CompCams will utilize a very aggressive lobe design. The idea here is simple, cylinder heads used in racing classes often have to sacrifice low lift airflow (.100-.300) in order to get the very high flow at high lift numbers. They have found that through camshaft design that they can generate more hp through a pretty simple concept. Now many will talk until they’re blue in the face that a good head has superior low and mid lift numbers and that is not entirely correct. SURPRISE!!!

If for example, you are going to use a 1.7 rocker to achieve .675 lift (with today’s valve springs and valve train parts is not a big deal for a dual purpose engine) and you are utilizing a new CompCams solid roller you are wasting your time focusing on lift numbers and here’s why. The aggressive lobe was designed to get the valve quickly (very, very quickly actually) into the .400 lift and higher range. You also sped the process up a bit by using a higher ratio rocker. The end result here is simple, you have a package that is designed to get the valve open quick, and stay open for as long as possible (when the valve spends most of it’s measurable time at high lift, it’s best to get your flow there). You also (since you read the above) have a well tuned exhaust tract that is aiding in the initial cylinder filling… In other words, IT’S ABOUT THE COMBINATION!!!

Like I said earlier, claims of big HP gains from one manufacturer to another are grossly exaggerated, and as far as I have been able to find, completely unsubstantiated. Most top flight manufacturers will have similar HP numbers, one will be higher than the other in some combinations, and that will be flipped in others. In general I would take your budget and application into consideration and spend your money where you will get the best results. If you can save $500 on heads and get a cam and rockers out if it, you may be better off than blowing your bank balance on perceived super duper heads.

Anyway, I hope this helps someone.[/quote]

watch the video, and like I stated many times,

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

viewtopic.php?f=52&t=148&p=182&hilit=flow+numbers#p182

http://www.superchevy.com/how-to/engine ... w-testing/

http://www.superchevy.com/how-to/engine ... omparison/

viewtopic.php?f=52&t=240&p=285&hilit=flow+numbers#p285

viewtopic.php?f=52&t=112&p=139&hilit=flow+numbers#p139

viewtopic.php?f=52&t=82&p=105&hilit=flow+numbers#p105

viewtopic.php?f=52&t=319&p=16170&hilit=comparing+big+block#p16170

viewtopic.php?f=52&t=333&p=407&hilit=flow+numbers#p407

viewtopic.php?f=52&t=796&p=1156&hilit=comparing+big+block#p1156

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

before you reach for your wallet, do some basic math and read a few dozen related links

http://www.wallaceracing.com/calcafhp.php

http://outintheshop.com/faq/casting/heads.html

http://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.superchevy.com/how-to/engines-drivetrain/0606ch-cylinder-head-performance-test/

http://www.jegs.com/p/ProMaxx-Perfo...hevy-Aluminum-Cylinder-Heads/2944747/10002/-1

http://garage.grumpysperformance.co...-for-cylinder-head-flow-numbers.240/#post-285

http://www.jegs.com/webapp/wcs/stor...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.gmhpclub.com/performancecalculators.htm

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/#post-37705

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.wallaceracing.com/calcafhp.php

http://hpwizard.com/engine-horsepower-calculator.html

http://www.hotrod.com/articles/airflow-research-cylinder-power/

http://garage.grumpysperformance.co...ed-up-fuelie-heads-for-cheap.2099/#post-56296

http://www.powerperformancenews.com/tech-articles/cylinder-head-tech-airflow-vs-power/

http://www.calculator.net/engine-horsepower-calculator.html

http://www.calculatoredge.com/new/horsepower.htm

reading the related info will be helpful

http://www.summitracing.com/parts/sum-151124

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-54091

http://garage.grumpysperformance.com/index.php?threads/what-springs.11352/#post-51960

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46627

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-44287

https://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

https://www.chevydiy.com/ultimate-chevy-big-inch-small-block-cylinder-heads-cheat-sheet/

https://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.superchevy.com/how-to/83138-choosing-best-small-block-heads/

http://www.enginebuildermag.com/2014/05/dont-gamble-when-choosing-cylinder-heads/

https://www.hemmings.com/magazine/m...Chevy-Small-Block-Cylinder-Heads/1848889.html

http://www.enginebuildermag.com/2017/03/cylinder-head-design-selection/

https://www.jegs.com/p/ProMaxx-Perf...hevy-Aluminum-Cylinder-Heads/2786544/10002/-1

https://www.flotekheads.com/2016/01/12/best-small-block-chevy-heads/

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-35948

http://garage.grumpysperformance.co...-vortec-heads-and-other-heads.401/#post-34996

http://garage.grumpysperformance.com/index.php?threads/vortec-info.529/#post-27299

http://garage.grumpysperformance.co...o-the-large-port-vortec-heads.1040/#post-1943

http://garage.grumpysperformance.com/index.php?threads/vortec-related-info.731/#post-1028

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

TRJ

http://trjperformance.com/cylinder-heads-top-end-kits-components/complete-heads/

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

TRJ

http://trjperformance.com/cylinder-heads-top-end-kits-components/complete-heads/

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

I found this (QUOTE BELOW) posted on a different site and while I agree with some statements and don,t agree with others its well worth reading thru for a different perspective, if you read thru the posted info I will agree that a great many cylinder heads get selected on the basis of posted flow numbers or price alone, and the fact is that the cam timing, intake design,operational rpm band, displacement ,compression ratio and exhaust scavenging all have a pronounced effect on how well the fuel and air flow thru a cylinder head port, and you don,t always get the best horse power by selecting the head with the highest posted and advertized flow numbers.

I'd also point out that the exhaust gases are physically forced out by the piston on the exhaust stroke and given a huge help in exiting the cylinder if you have a properly designed header that scavenges the cylinder,and that rapidly exiting exhaust gas does help to draw in the next intake charge PROVIDED the cam timing and exhaust header are properly matched, and since flow benches measure flow at a static valve lift and engine have a piston rotating at maybe 6000rpm and valve that opens and closes 55 times PER SECOND and theres no exhaust scavenging ,while the heads tested,theres no way in hell that a flow bench accurately duplicates flow conditions in a running engine

http://www.strokerengine.com/SBCHeadsFlow.html

http://garage.grumpysperformance.com/index.php?threads/sellecting-cylinder-heads.796/#post-49711

[quote="jsup"]

Shopping for Heads

As I started to dig down and learn more, I found out that a lot of marketing hype was just that, hype.

For guys doing builds, $1500+ is a lot of money, so I put together the facts, as I found them, and had them verified my findings through six independent, qualified sources. One source is an areonautical engineer who worked for a major military aircraft manufacturer and designed fighter jets. He decided he wanted to build race engines, so he now makes his living building sprint car, drag, street motors. He's done 100s of motors and has over a decade of experience. That is typical of the quality of my research.

This paper was the genesis of getting me kicked off another forum, as a forum sponsor did not like the fact that my findings were in conflict with his marketing. I hope people here can read it for what it is, a sober assessment of some of what goes into head design and items for consideration when choosing a head.

All my information again, has been vetted by a 7th source, and still withstands the test of facts. I am not saying what I write is gospel, but it's one man's view. I spent over a moth of research and I hope that my countless hours of work prove useful for someone.

I am not an engineer, I am not a tech. I am a sales/marketing guy for a living, so I relied on people who are techs and engineers for my information.

I have studied the subject in quite some depth, for quite some time. I did not rely on marketing brochures or manufacturer’s claims. I have spent the last month talking to Engineers, FOUR of them. One of which is a close friend who has 7 Engineering degrees from Steven’s Institute here in Jersey. Oh, did I mention he even carries a Masters in Engineering? But wtf does he know? Happens to be he’s an avid racer and part time engine builder. Not a professional builder, but he puts his own engines together. He is one of the few people who ever finished all seven disciplines of engineering in the history of Stevens, not a stupid man for sure.

Two engineers who have offered their expertise on fluid dynamics and have verified this information independently of each other. The first has 25 years of fluid dynamics experience working as an engineer designing shocks. The second, is an aeronautical engineer and engine builder. The last is an engineer who’s job it is to design heads, who is not a forum member. Also, I sat with two engine builders who both have a long history and great reputation. I challenge ANYONE to dismiss the DECADES of expertise I have assembled prior to putting out this information and request please ensure your expertise can hold a candle to what I have addressed in the aforementioned paragraph.

Although I am no technical expert, being smarter than your average bar stool I have learned the following. I have had each of them review this information for accuracy before posting, and they have blessed it as completely accurate.

First of all, I anticipate you're going to hear a lot of noise about this and that. Typically you're going to hear about flow numbers and port size. You are going to be told that the ideal head is the one with the biggest flow and the smallest port. Like all urban legends, there is some truth to that but also like urban legends, has little basis in fact. Port size and flow are not the “be all to end all” in head selection.

You're going to hear a lot of noise from the self appointed "experts", many who probably need help tying their shoes. Their expertise will be based on sweeping the floors at a high performance shop in the middle of nowhere while some have even read a brochure or two. You will find even more who went to the track once or twice, with many who know a guy who did something a few years back, or have actually ridden in really fast cars. So I recommend you consider the sources relative expertise as it relates to the subject matter at hand when weighing such advice. I am no such technical expert. I'm just a guy who likes to learn about this stuff, so I go to the experts in the field and ask the questions, and listen to the answers, and learn what I can when I can based on my capacity.

Marketing brochures have little value. For example, I wanted to know about disc injectors so I called Lucas and talked directly to the engineer who designed them, for over an hour....now, that does not make me an expert, however, I try to relay the information I gained since we all can't talk to the guy this is the best one can do in this situation.

And finally, never trust an opinion from someone who has a vested interest in the outcome. Manufacturer's lie to sell product, simple. If a claim seems a little preposterous, it probably is. You will not see a 40HP difference from one manufacturer's head to another if compared to like products in respective product lines.

I find value in engineering. I find little value in people going through a catalog and picking out the coolest most expensive parts in the consumer realm, screwing them together and calling themselves experts. I look to racing as the arbiter of quality, process, and results. BILLIONS of dollars a year is spent on R&D in racing circles so it's a good place to reference, even for a street build...An example I like to use is kinda like a guy bragging about his Sony receiver to a guy who has a wall full of tube McIntoch equipment. Two different worlds and two different levels of equipment, but doesn't mean you can't learn from the higher end, when building the lower end.

Bottom line I have put considerable time, effort, and energy into developing this information , and I would appreciate it if it is read and digested and people don’t start spouting off about flow numbers. I hope that we all can learn something from my research and the great amount of time I spent. I will recite just the facts as the experts have presented them. I challenge ANYONE to find fault with the facts I will present going forward. I recommend you call someone, if you have trouble with the big words and intangible concepts.

But I digress, so let's cut through the crap I expect you're going to hear:

1. It's all about flow....true and false...

Looking at cylinder head flow on a flow bench represents simply how restrictive the intake tract is, that’s it, period. It is one metric that contributes to cylinder head performance, there are others, arguably, more important. In other words, are you breathing through a straw or a garden hose… Unfortunately for everyone that develops engine combinations; air isn’t simply sucked through the intake tract as a constant stream. Elements such as intake valve closing, pressure bleeding through the ever so slightly opened intake valve cause what is commonly referred to as reversion. When was the last time you ever heard that mentioned here? This is important because it demonstrates that the one dimensional view of a dry flow bench does not take into consideration true operational environments.

The “reversion” is a pulse of pressure that is part of the longitudinal wave (look it up) traveling back up the intake track. You see it push back through the carburetor when the timing of the event, actually the tuning of the intake tract, is off and the pulse is passing too far up the intake tract. Who hasn’t seen fuel spouting out of the intake once or twice? What do you think that does to engine performance? Common sense dictates that this is not a good situation, so port design matched to intake design is of consummate importance, above and beyond flow numbers.

Another important aspect is that air cannot compress at any velocity we will find inside an intake tract so it must speed up or slow down with changes in cross sectional area. (again look it up) This represents the biggest shortcoming of the DRY flow bench. The bench does not measure velocity, nor does it attempt to predict or model any of the increases or decreases encountered throughout the intake tract and how they are affecting flow. This means that all too often an intake tract is ineffective at controlling intake velocities throughout the entire operating range for the particular engine, throughout the entire intake tract (both are a big issue). In other words, FLOW NUMBERS DON’T TELL THE WHOLE STORY ON A ANY FLOW BENCH! In order for air to compress to a meaningful level, and achieve above 100% VE, air speed of .6 mach is necessary, that air speed is rarely reached inside an engine.

This also leads to problems when working with the wet flow development. The concept of wet flow makes sense to most people; fuel is atomized into the intake tract and needs to stay evenly distributed all the way into the combustion chamber. Many experienced designers have found the all too common problem associated with converting a design from gasoline to alcohol. Since we have different mixtures associated with the fuels the density and overall saturation changes as well. So gas burns differently than alcohol, and you have to have ore of one than the other in and of itself is not really earth shattering, HOWEVER, this serves to demonstrate that it’s about DESIGN not just flow. Another example where flow numbers don’t matter. With the wet flow bench one can at least attempt to identify and monitor problematic areas of the intake tract (designers whish there were even more robust methods)

The advantage to wet flow is that engineers can build a head on paper, bolt it to a wet flow bench, and see if reality and paper line up. If they don't, they can adjust and re-try. This significantly accelerates R&D as it is a true representation of what happens in the operational environment under operational conditions. Read as, we can see the flow, but not at 6000 rpms, so although better than dry flow, not perfect.

The dry flow method of development is what I call hack and guess . What people will do is take a set of heads, and hand port them. Each cyl will be made slightly different than the other, then the head is put on a flow bench. The cyl that has the highest number is the winner. Then you take another set and do the same thing.... and again, until you're convinced you have the best number you can get. This does not tell you anything about the quality of the flow, just the quantity. Also, does nothing to aide in the design of the flow, simply modifications after the fact of design.

An even bigger problem is once airflow becomes a problem upstream the entire tract is not designed in an effort to correct this, it simply stays somewhat messed up and depending on how the rest of the tract is design can potentially get worse as it flows, in other words, it’s a mess. The quality of the airflow is important, not only the quantity. What this results in is that irregular airflow causes problems with the mixture and subsequently, causes problems with the proper air/fuel mixture getting into the cylinder. If you talk to people who design on wet flow benches, they will tell you that yes, their dry flow numbers on paper are not as good as some other manufactures. HOWEVER, it is their position that they can suck more fuel into the cylinder more cleanly and efficiently based on their designs (the resulting changes to promote better flow characteristics on the wet bench will often lower flow numbers on the dry bench slightly, negating the port size/CFM flow argument TOTALLY). They will also tell you that dry flow numbers are utter bullshit and have no indication of the actual performance of a head outside of the one metric that a dry bench measures. That is their position, and it makes total sense.

Take a time out, go get a drink, and come back for the rest. It is far easier to parrot marketing crap than to think deeply as to what goes into the development of a head and those aspects which embody making power. I know this can be tiresome and trying, but I did the work dammit, and you’re going to read it.

2. Smaller port size, the better for same flow

Looking above we see that there is a great deal of effort put into not only how much air could be pulled through the port, but mostly, how it will get through the port, that’s what is really important, getting air into the engine during actual operation effectively and efficiently, it’s not all about VOLUME, it’s about QUALITY. You must always remember that a flow bench is only measuring how easily air can be pulled into the cylinder, not how much fuel is in that stream or the QUALITY of the flow when operation is actually taking place. This means that when comparing cylinder head sizes the most important aspect as the SHAPE of the port and how that shape relates when viewing flow all the way to the combustion chamber. Airflow must be controlled, and hence the shape and measurements of the port are far more important that just looking at flow versus runner size. In other words DRY FLOW BENCHES ARE USELESS IN HEAD DESIGN AND FLOW VS. RUNNER SIZE IS A MYTH.

Again; a flow bench does not measure how much air will be pulled through the port during operation or the quality of delivery of that air, it measures the most simple of measurements, how easily it can be pulled though in a vacuum. Which tells you nothing about head performance.

When looking to design a port design a big consideration is to see what the airflow demands will be; they also must look to what type and how much fuel will be induced into the mix, what RPM the engine will be operating at and lastly, must look past the port into the combustion chamber and into the intake manifold. Again, a head with lower flow bench numbers which produces better charge delivery (through cleaner airflow and physics) and does so throughout the operating range of the engine, is a better, more efficient head that creates more power. Despite the mantra we hear here about efficiency being measured by some made up formula of port size vs. flow numbers, that is not the case in true engineering, or the laws of physics. It is simplistic marketing hype for the simpleton masses.

Significant hp can be gained or lost by port design regardless of the airflow number changes. GASP! A cutting edge cylinder head not only has low restriction and a proper shape for tuning purposes it also has to control velocity along with cutting back on irregular flow (turbulence). Now, a combustion chamber can promote flow or hinder it, it can also promote proper filling and flame travel (often trade offs); how a cylinder is filled is as important as how much of it is filled; all of the above have to balanced throughout the design process as there is no end all be all design that contains the best of every aspect. Flame travel, ever hear flame travel mentioned here? I didn’t think so. No one here wants to think real hard about stuff, it’s easier to spew meaningless numbers.

Another very complicated aspect of how the engine makes its power, valve and spark plug placement and combustion chamber shape have to consider this as well as how much air it can pass! To sum up, without the benefit of a wet flow bench, you would never be certain as to how the design works (and even the wet flow bench leaves something to be desired amongst designers but hey it’s a step in the right direction that measures additional variables). Now, that’s not to say you can’t get lucky by coping someone else’s design, or through trial and error like many speed shops, however, there is no science behind guessing on a dry flow bench (just what worked well in the past…). It’s brute force vs. elegant design.

3. Exhaust flow has real meaning.

This is one that every professional I talk outright laughs at; the idea that a cylinder head has to flow a ton on the exhaust side to make good power. When I ask this question I usually get a response like “a 900hp race engine has an exhaust port that flows 250cfm, so why would you feel that a street engine needs one to support 500-600hp?”. Does sound ridiculous on the face of it doesn’t it?

Think about this in terms of airflow demand just as we would the intake side. Again, the shape and tuning of the exhaust is what pulls the last bit of exhaust out and first bit of intake charge in, not the flow number. In other words, in the absence of real design work being done, go for brute force, or big numbers. This is not a design, this is a guess. Think of a siphon, if you’re simply letting water run out of a hose, vs, a siphon sucking it through, that’s what port design and wet flow (on the intake side) will do for you and that is why exhaust flow numbers are meaningless. That is why we put X pipes in our cars. Isn’t it? If you don’t subscribe to the above, I will expect we should all be pulling out our X pipes tomorrow..

Therefore, a few engine builders have expressed that they do not feel that restriction in the exhaust port is anything to really look at, the flow bench number, and it has no value. To them it’s all about tuning that tract to do the above. Many will cite how unimportant cylinder head flow numbers become when a supercharger is added to the intake side as some of the reasoning they feel that exhaust port flow numbers are not the hot ticket. So essentially, this exhaust flow thing you’re going to hear is utter nonsense perpetuated by the ignorant, ill informed and uneducated.

I have also learned other things about engine design and they are also important, as they relate to head design. There are aspects of engine design such as:

A modern camshaft like one produced by CompCams will utilize a very aggressive lobe design. The idea here is simple, cylinder heads used in racing classes often have to sacrifice low lift airflow (.100-.300) in order to get the very high flow at high lift numbers. They have found that through camshaft design that they can generate more hp through a pretty simple concept. Now many will talk until they’re blue in the face that a good head has superior low and mid lift numbers and that is not entirely correct. SURPRISE!!!

If for example, you are going to use a 1.7 rocker to achieve .675 lift (with today’s valve springs and valve train parts is not a big deal for a dual purpose engine) and you are utilizing a new CompCams solid roller you are wasting your time focusing on lift numbers and here’s why. The aggressive lobe was designed to get the valve quickly (very, very quickly actually) into the .400 lift and higher range. You also sped the process up a bit by using a higher ratio rocker. The end result here is simple, you have a package that is designed to get the valve open quick, and stay open for as long as possible (when the valve spends most of it’s measurable time at high lift, it’s best to get your flow there). You also (since you read the above) have a well tuned exhaust tract that is aiding in the initial cylinder filling… In other words, IT’S ABOUT THE COMBINATION!!!

Like I said earlier, claims of big HP gains from one manufacturer to another are grossly exaggerated, and as far as I have been able to find, completely unsubstantiated. Most top flight manufacturers will have similar HP numbers, one will be higher than the other in some combinations, and that will be flipped in others. In general I would take your budget and application into consideration and spend your money where you will get the best results. If you can save $500 on heads and get a cam and rockers out if it, you may be better off than blowing your bank balance on perceived super duper heads.

Anyway, I hope this helps someone.[/quote]

its the combo of the engines,

compression,

displacement ,

cam timing

and the exhaust scavenging ,

and the intake manifold design,

NOT the intake port cross sectional area,

that are the most critical factors, in the engines lower rpm and mid rpm torque.

but for damn sure an intake runner port can be small enough to noticeably restrict upper mid range and peak power significantly

RELATED THREADS

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/

viewtopic.php?f=52&t=148&p=182&hilit=flow+numbers#p182

http://www.superchevy.com/how-to/engine ... w-testing/

http://www.superchevy.com/how-to/engine ... omparison/

viewtopic.php?f=52&t=240&p=285&hilit=flow+numbers#p285

viewtopic.php?f=52&t=112&p=139&hilit=flow+numbers#p139

viewtopic.php?f=52&t=82&p=105&hilit=flow+numbers#p105

viewtopic.php?f=52&t=319&p=16170&hilit=comparing+big+block#p16170

viewtopic.php?f=52&t=333&p=407&hilit=flow+numbers#p407

viewtopic.php?f=52&t=796&p=1156&hilit=comparing+big+block#p1156

ID suggest you select from heads from these sources

Jegs; 800/345-4545; Jegs.com

Summit Racing; 800/230-3030; SummitRacing.com

Scoggin-Dickey Parts Center; 800/456-0211; ScogginDickey.com

before you reach for your wallet, do some basic math and read a few dozen related links

http://www.wallaceracing.com/calcafhp.php

http://outintheshop.com/faq/casting/heads.html

http://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

http://www.superchevy.com/how-to/engines-drivetrain/0606ch-cylinder-head-performance-test/

http://www.jegs.com/p/ProMaxx-Perfo...hevy-Aluminum-Cylinder-Heads/2944747/10002/-1

http://garage.grumpysperformance.co...-for-cylinder-head-flow-numbers.240/#post-285

http://www.jegs.com/webapp/wcs/stor...&submodel=&engine=&Nrpp=&No=&persistYmm=false

http://www.superchevy.com/how-to/en...-0902-chevy-engine-port-variations-measuring/

http://www.gmhpclub.com/performancecalculators.htm

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/#post-37705

USE THE CALCULATORS to match port size to intended rpm levels... but keep in mind valve lift and port flow limitations

http://www.wallaceracing.com/runnertorquecalc.php

http://www.wallaceracing.com/ca-calc.php

http://www.wallaceracing.com/area-under-curve.php

http://www.wallaceracing.com/chokepoint.php

http://www.wallaceracing.com/header_length.php

http://www.circletrack.com/enginetech/1 ... ch_engine/

http://www.wallaceracing.com/calcafhp.php

http://hpwizard.com/engine-horsepower-calculator.html

http://www.hotrod.com/articles/airflow-research-cylinder-power/

http://garage.grumpysperformance.co...ed-up-fuelie-heads-for-cheap.2099/#post-56296

http://www.powerperformancenews.com/tech-articles/cylinder-head-tech-airflow-vs-power/

http://www.calculator.net/engine-horsepower-calculator.html

http://www.calculatoredge.com/new/horsepower.htm

reading the related info will be helpful

http://www.summitracing.com/parts/sum-151124

http://garage.grumpysperformance.co...train-clearances-and-problems.528/#post-57678

http://garage.grumpysperformance.co...ting-up-the-valve-train.181/page-2#post-54091

http://garage.grumpysperformance.com/index.php?threads/what-springs.11352/#post-51960

http://garage.grumpysperformance.co...-loads-and-installed-height.10709/#post-46627

http://garage.grumpysperformance.com/index.php?threads/removing-valve-seals.4283/#post-44287

https://www.hotrod.com/articles/ccrp-1209-eight-budget-sbc-head-shootout/

https://www.chevydiy.com/ultimate-chevy-big-inch-small-block-cylinder-heads-cheat-sheet/

https://www.chevydiy.com/the-complete-cylinder-head-guide-for-chevy-small-block-engines/

http://www.superchevy.com/how-to/83138-choosing-best-small-block-heads/

http://www.enginebuildermag.com/2014/05/dont-gamble-when-choosing-cylinder-heads/

https://www.hemmings.com/magazine/m...Chevy-Small-Block-Cylinder-Heads/1848889.html

http://www.enginebuildermag.com/2017/03/cylinder-head-design-selection/

https://www.jegs.com/p/ProMaxx-Perf...hevy-Aluminum-Cylinder-Heads/2786544/10002/-1

https://www.flotekheads.com/2016/01/12/best-small-block-chevy-heads/

http://garage.grumpysperformance.com/index.php?threads/the-new-215cc-vortec-heads.266/#post-35948

http://garage.grumpysperformance.co...-vortec-heads-and-other-heads.401/#post-34996

http://garage.grumpysperformance.com/index.php?threads/vortec-info.529/#post-27299

http://garage.grumpysperformance.co...o-the-large-port-vortec-heads.1040/#post-1943

http://garage.grumpysperformance.com/index.php?threads/vortec-related-info.731/#post-1028

TRICKFLOW

http://www.trickflow.com/egnsearch.asp? ... 4294867081

http://www.trickflow.com/customerservice

1-330-630-1555 • 1-888-841-6556

BRODIX

http://www.brodix.com/heads/heads.html

479.394.1075

DART

http://www.dartheads.com/products/cylinder-heads

Dart Machinery; 248/362-1188; DartHeads.com

AIR FLOW RESEARCH

http://www.airflowresearch.com/

toll free: 877-892-8844

tel: 661-257-8124

Patriot Performance

Patriot Performance; 888/462-8276; Patriot-Performance.com

TRJ

http://trjperformance.com/cylinder-heads-top-end-kits-components/complete-heads/

RHS

http://www.racingheadservice.com/rhs/cylinder-headshtml

Toll Free: 877-776-4323

Local: 901-259-1134

EDELBROCK

http://www.edelbrock.com/automotive_new ... main.shtml

Edelbrock; 310/781-2222; Edelbrock.com

BMP (world products)

http://www.theengineshop.com/products/cylinder-heads

Tel: 631-737-0372

Fax: 631-737-0467

BUTLER PERFORMANCE

http://www.butlerperformance.com/products/cylinder_heads/cylinder_head_labor.html

866-762-7527

BLUE PRINT ENGINES

http://www.blueprintengines.com/ind...sb-chevy-aluminum-cylinder-heads-cnc-machined

1800-483-4263

TRJ

http://trjperformance.com/cylinder-heads-top-end-kits-components/complete-heads/

PRO-FILER

https://www.profilerperformance.com/

937‐846‐1333

Last edited by a moderator: