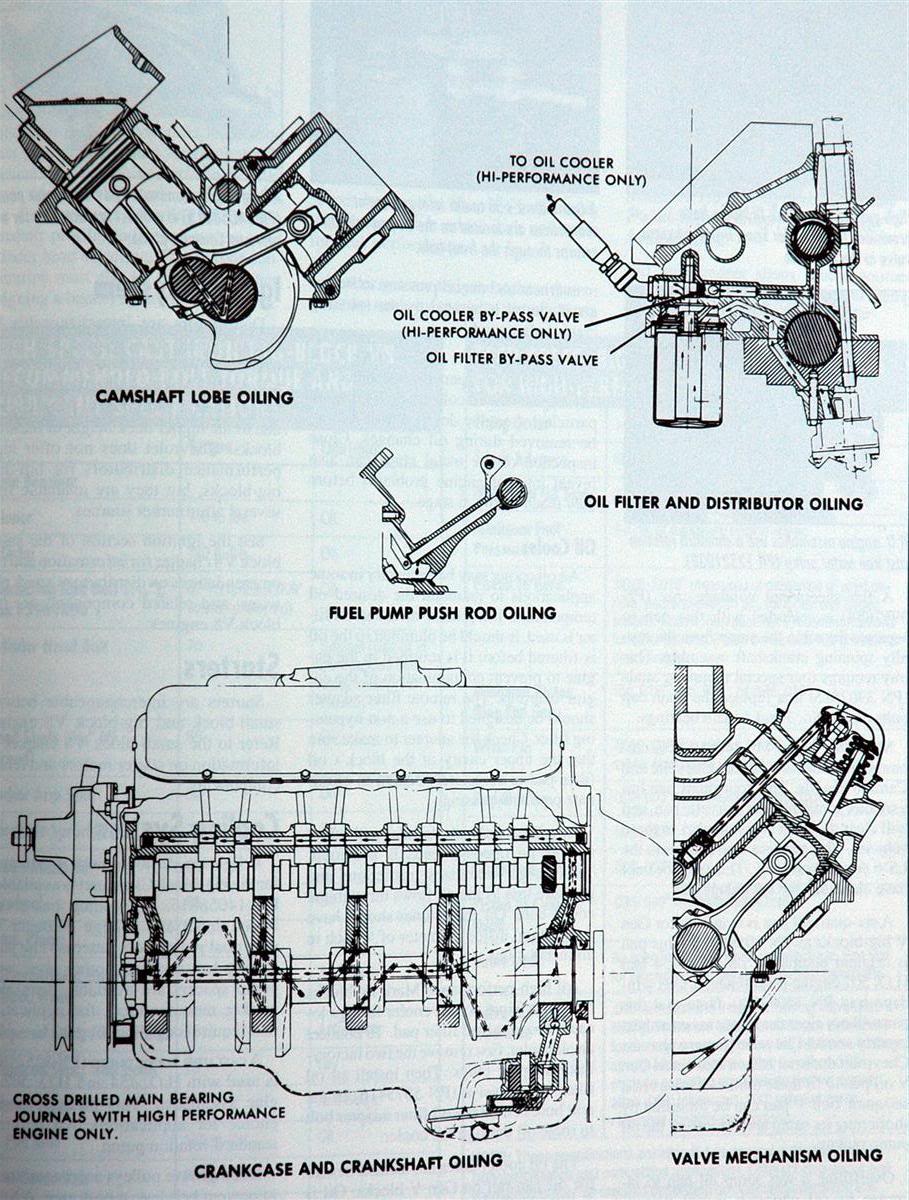

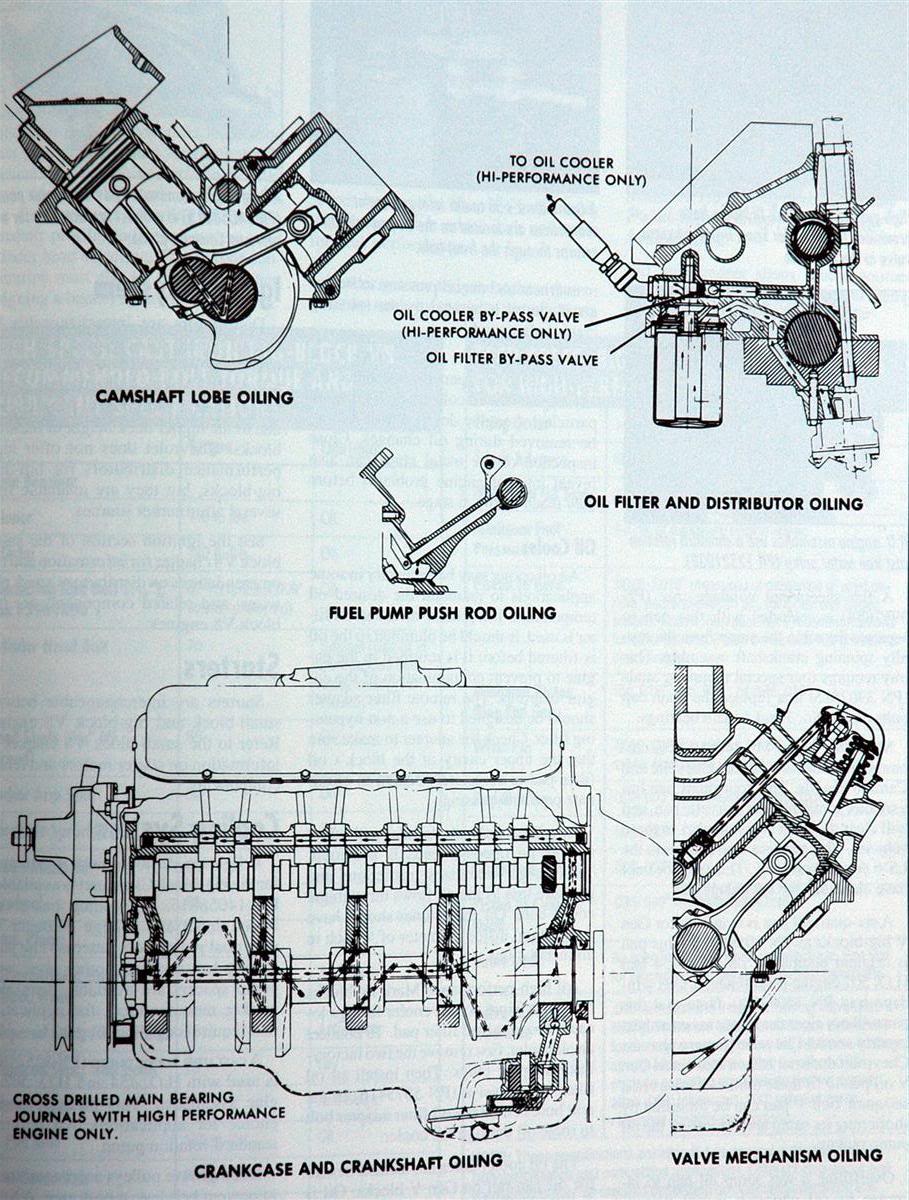

SOME OLDER BUILDERS ARE UNDER THE IMPRESSION THAT FORCING ALL THE OIL FLOW THRU THE FILTER ELEMENT IS A GOOD IDEA,..YOU CAN,T compress oil, THE OIL PUMP, PUSHES A SET SWEEP VOLUME DICTATED BY THE GEAR AND PUMP SIZE AND RPM LEVEL, .most have not thought it thru carefully, 90% of the guys use the standard disposable filters with those thin synthetic or paper elements, the bye pass is there for a reason, and in my opinion its a good idea to leave it functional, when oil is cold or when theres a VERY rapid change in rpms the bye-pass tends to keep the pressure spikes that result, from rupturing the filter element, a bit of unfiltered oil momentarily is better than having a filter element rupture,internally as your very unlikely to know that its failed and much of the oil is now unfiltered as a result, or pull loose from its glued seams due to a pressure spike, resulting in a constant flow of partly unfiltered oil

a lot of guys used to do that mod, thinking it would be beneficial to force all oil thru the filter, now in theory it helps, but I have yet to see any real proof its all that helpful to engine durability, remember any oil goes thru the pump before it reaches the oil filter and theres always oil being thrown off the crank and windage carries some oil around with the crank, before its dropped into the sump so a windage trays helpful, if small debris gets into the oil pump it will damage the gears or clog the oil pump pick-up screen well before the oil filter is ever going to see that debris.

thats one reason I think magnets are useful also as they trap metallic crap most likely to cause damage.

READ THESE THREADS

viewtopic.php?f=54&t=120

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=117

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=3144

viewtopic.php?f=54&t=3834

viewtopic.php?f=54&t=52

http://people.msoe.edu/~yoderw/oilfilte ... study.html

a lot of guys used to do that mod, thinking it would be beneficial to force all oil thru the filter, now in theory it helps, but I have yet to see any real proof its all that helpful to engine durability, remember any oil goes thru the pump before it reaches the oil filter and theres always oil being thrown off the crank and windage carries some oil around with the crank, before its dropped into the sump so a windage trays helpful, if small debris gets into the oil pump it will damage the gears or clog the oil pump pick-up screen well before the oil filter is ever going to see that debris.

thats one reason I think magnets are useful also as they trap metallic crap most likely to cause damage.

READ THESE THREADS

viewtopic.php?f=54&t=120

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=117

viewtopic.php?f=54&t=2187

viewtopic.php?f=54&t=3536

viewtopic.php?f=54&t=3144

viewtopic.php?f=54&t=3834

viewtopic.php?f=54&t=52

http://people.msoe.edu/~yoderw/oilfilte ... study.html