sooner or later youll be offered a killer deal on a block thats just too good to pass up, but on real close inspection youll find it needs a cylinder bore job or in some cases a cylinder replaced due to a crack ..that is, of course a (TOTAL SURPRISE TO THE SELLER) NOW IN MOST CASES YOU CAN,T FIND THIS STUFF OUT WITHOUT HAVING A MACHINE SHOP CHECK OUT THAT (bargain)

AND BY THEN THE SELLER WILL INSIST ITS YOUR PROBLEM, (if you can find him)

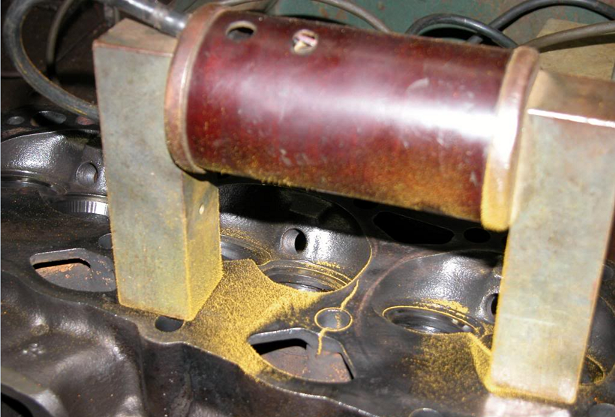

NOW SLEEVING A BLOCK CAN GET fairly EXPENSIVE, BUT IF ITS JUST A SINGLE CYLINDER , and if the repair work is done correctly ,

ITS RARELY A PROBLEM IF YOU BOUGHT THE BLOCK CHEAP ENOUGH

the truth is that a sleeve is just as strong or stronger,

than the original cylinder if its been installed correctly.

but you generally don,t want to install two sleeves installed on the same bank on the same block side by side does provide a less rigid block,as a single sleeve is usually just fine but two side by side, well, Id look for a new block

http://www.popularhotrodding.com/engine ... index.html

http://www.larryspower.com/engine/Sleev ... #Packaging

http://www.precisionenginetech.com/tech ... ld-blocks/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

https://www.hotrod.com/articles/how-to-sleeve-an-engine-block/

http://www.superchevy.com/how-to/engines-drivetrain/1804-re-sleeve-save-matching-numbers-block/

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/#post-7077

http://garage.grumpysperformance.com/index.php?threads/thrust-bearing-wear.619/#post-10925

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/#post-15557

http://garage.grumpysperformance.co...-about-your-potential-dream-bbc-combos.14607/

I was recently asked what block casting numbers a guy should look for,

to insure that the block he was going to base his engine on was more likely to have the thicker casting,

and cylinder wall depth that would safely allow a .030-or even a .060 over bore?

well youll ideally want a pre-1970 block for either the SBC or BBC engine.

keep in mind that block is now almost 50 years old you have no idea how in was stored or treated previously,

or how much internal coolant passage rust damage is hidden in the block's internal passages after all that time.

pre-1970 block casting technology tended to use MARGINALLY thicker casting's,

that the post 170 blocks with their slightly improved casting tech.

but core shift was more likely so its a bit off in its bore wall consistency,

a no-win situation, you could have thicker castings, that were slightly off-set ,

making it just as weak as a later thinner casting.

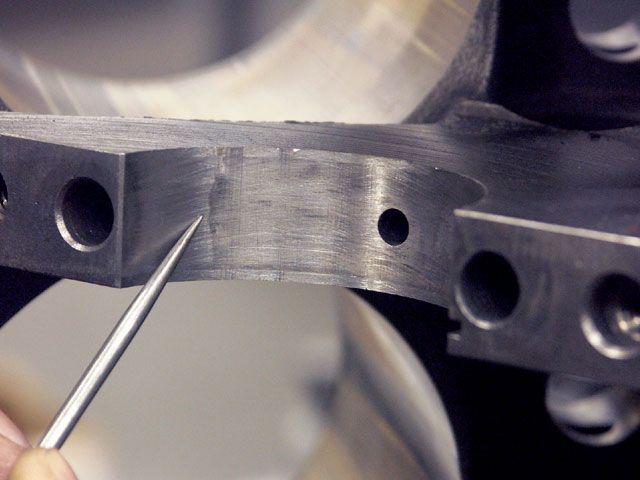

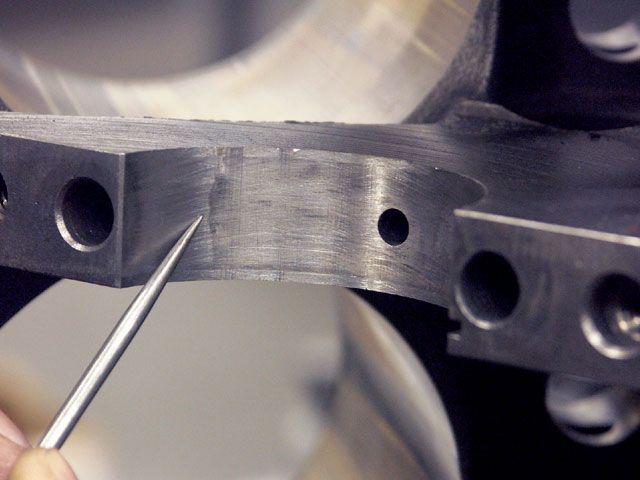

the truth here is if your intention is to bore any stock block over .030,

you should first sonic test the bore wall thickness and consistency.

that being stated, a DART or similar aftermarket WORLD PRODUCTS block,

will have a significantly thicker casting with a stronger alloy.

if your going to throw $70-$1000 plus in precision machine work into a performance engine,

your much safer financially in the long term doing that on the much stronger aftermarket or bowtie block.

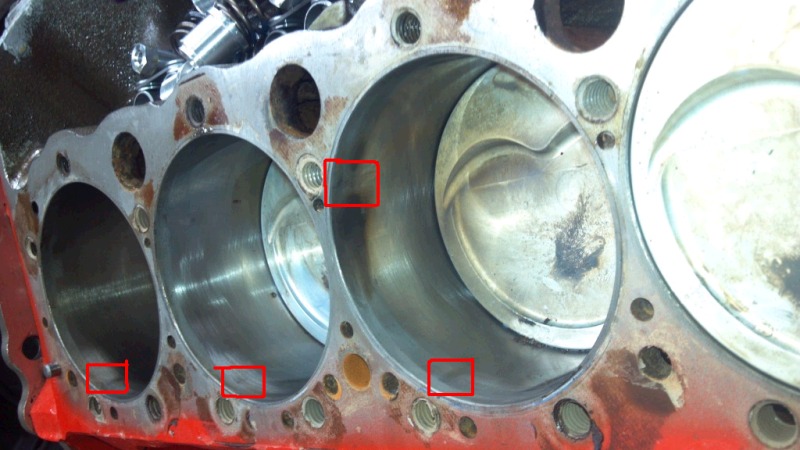

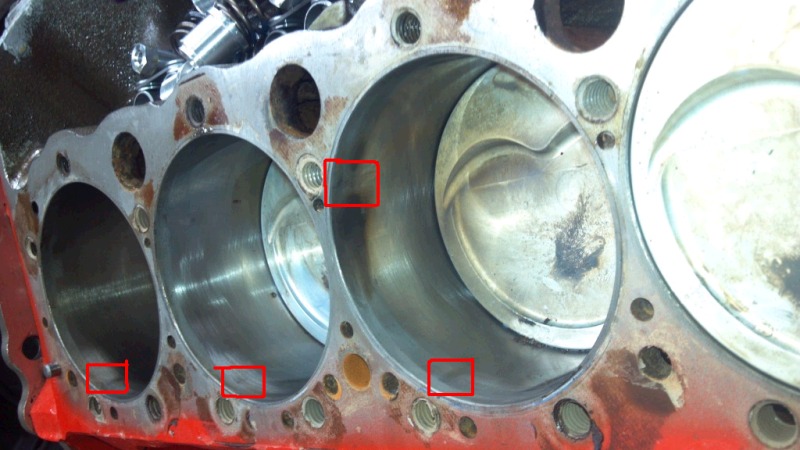

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

lifter bores

and lifter gallery

,piston bore walls,

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

http://garage.grumpysperformance.com/index.php?threads/casting-numbers-vin.93/#post-29983

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/blueprinting-a-block.49/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/darts-new-sbc-block.47/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-bbc-vs-a-sbc.1009/

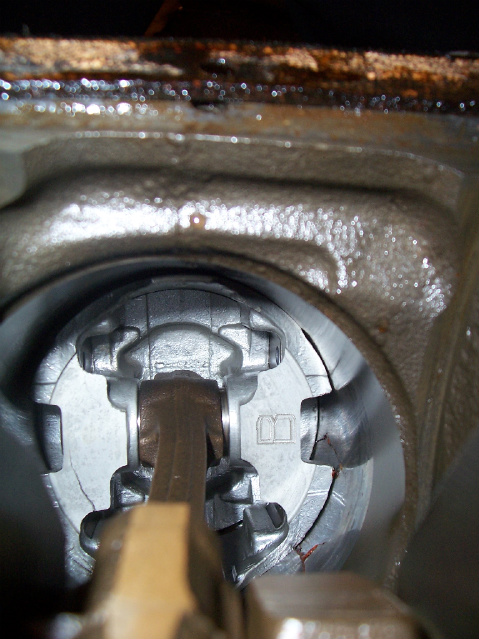

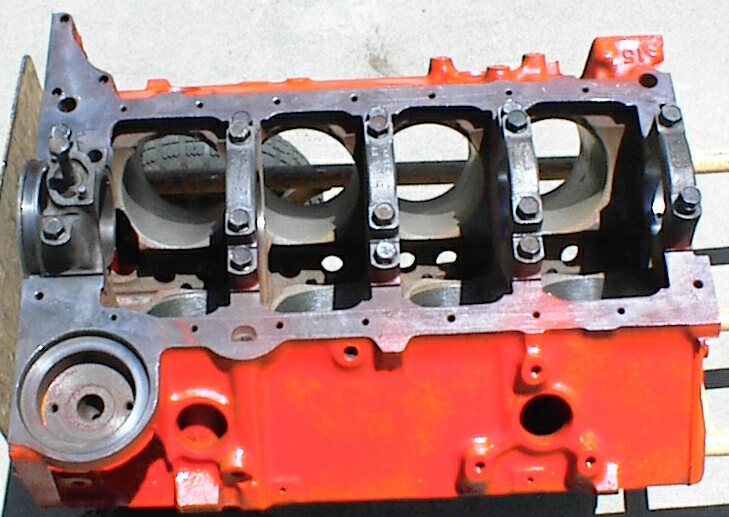

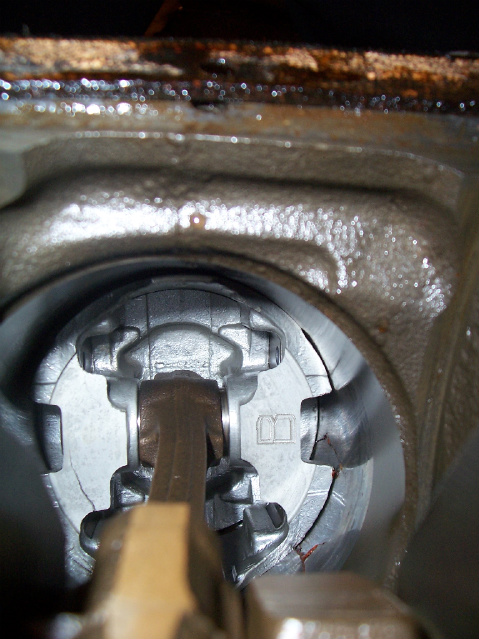

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

read these threads

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

sleeving the bore,some times its the only way to save a block, but in many cases the O.E.M. blocks are so thinly cast that youll have bore distortion and less than ideal bore wall thickness and less than ideal ring sealing, making swapping to an aftermarket DART or BOWTIE block a better long term option

AND BY THEN THE SELLER WILL INSIST ITS YOUR PROBLEM, (if you can find him)

NOW SLEEVING A BLOCK CAN GET fairly EXPENSIVE, BUT IF ITS JUST A SINGLE CYLINDER , and if the repair work is done correctly ,

ITS RARELY A PROBLEM IF YOU BOUGHT THE BLOCK CHEAP ENOUGH

the truth is that a sleeve is just as strong or stronger,

than the original cylinder if its been installed correctly.

but you generally don,t want to install two sleeves installed on the same bank on the same block side by side does provide a less rigid block,as a single sleeve is usually just fine but two side by side, well, Id look for a new block

http://www.popularhotrodding.com/engine ... index.html

http://www.larryspower.com/engine/Sleev ... #Packaging

http://www.precisionenginetech.com/tech ... ld-blocks/

http://garage.grumpysperformance.com/index.php?threads/installing-splayed-caps.7267/#post-68837

https://www.hotrod.com/articles/how-to-sleeve-an-engine-block/

http://www.superchevy.com/how-to/engines-drivetrain/1804-re-sleeve-save-matching-numbers-block/

http://garage.grumpysperformance.com/index.php?threads/bearing-clearances.2726/#post-7077

http://garage.grumpysperformance.com/index.php?threads/thrust-bearing-wear.619/#post-10925

http://garage.grumpysperformance.com/index.php?threads/another-496bbc.5123/#post-15557

http://garage.grumpysperformance.co...-about-your-potential-dream-bbc-combos.14607/

I was recently asked what block casting numbers a guy should look for,

to insure that the block he was going to base his engine on was more likely to have the thicker casting,

and cylinder wall depth that would safely allow a .030-or even a .060 over bore?

well youll ideally want a pre-1970 block for either the SBC or BBC engine.

keep in mind that block is now almost 50 years old you have no idea how in was stored or treated previously,

or how much internal coolant passage rust damage is hidden in the block's internal passages after all that time.

pre-1970 block casting technology tended to use MARGINALLY thicker casting's,

that the post 170 blocks with their slightly improved casting tech.

but core shift was more likely so its a bit off in its bore wall consistency,

a no-win situation, you could have thicker castings, that were slightly off-set ,

making it just as weak as a later thinner casting.

the truth here is if your intention is to bore any stock block over .030,

you should first sonic test the bore wall thickness and consistency.

that being stated, a DART or similar aftermarket WORLD PRODUCTS block,

will have a significantly thicker casting with a stronger alloy.

if your going to throw $70-$1000 plus in precision machine work into a performance engine,

your much safer financially in the long term doing that on the much stronger aftermarket or bowtie block.

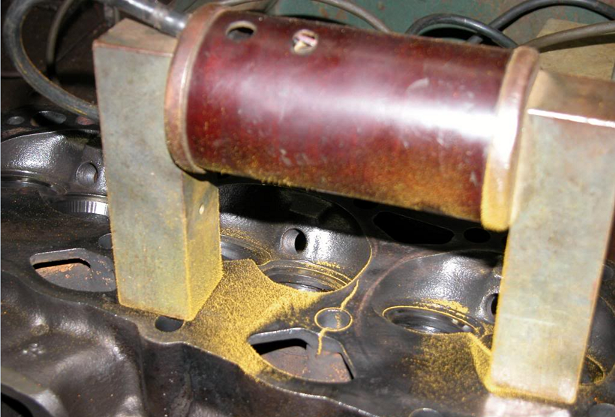

clean any block you buy and look for obvious cracks and if you have doubts get the machine shop to mag or dye test the block or heads

lifter bores

and lifter gallery

,piston bore walls,

block main cap web support areas

heads between the valves in valve seat area

look for stripped head and manifold and oil pan mounting bolt threads,

in threaded holes and cracks in block radiating from the holes

http://garage.grumpysperformance.com/index.php?threads/casting-numbers-vin.93/#post-29983

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/blueprinting-a-block.49/

http://garage.grumpysperformance.com/index.php?threads/sbc-cylinder-wall-thickness.7646/

http://garage.grumpysperformance.com/index.php?threads/which-dart-shp-4-0-or-4-125.3219/

http://garage.grumpysperformance.com/index.php?threads/block-choice.10472/

http://garage.grumpysperformance.com/index.php?threads/darts-new-sbc-block.47/

http://garage.grumpysperformance.com/index.php?threads/why-build-a-bbc-vs-a-sbc.1009/

TWO BOLT MAIN CAP BLOCK

4 bolt SBC block

read these threads

http://garage.grumpysperformance.co...block-cylinder-wall-thickness.976/#post-22976

sleeving the bore,some times its the only way to save a block, but in many cases the O.E.M. blocks are so thinly cast that youll have bore distortion and less than ideal bore wall thickness and less than ideal ring sealing, making swapping to an aftermarket DART or BOWTIE block a better long term option

Last edited by a moderator: