if you have a CAST IRON CAM GEAR whether its machined on a CAST IRON CAM or PRESSED onto a STEEL billet core a CAST IRON stock style DISTRIBUTOR GEAR IS WHAT YOU NEED, BUT..if you have a STEEL BILLET CAM CORE (NORMALLY ONLY FOUND ON SOME ROLLER CAMS) with A STEEL GEAR MACHINED ON THE CORE a bronze/ALUMINUM STYLE GEAR IS WHATS USUALLY NECESSARY, BUT CONTACT THE CAM MANUFACTURER, AND ASK, BEFORE GUESSING AT THIS

HERE READ this link also

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://www.summitracing.com/search/part-type/distributor-gears/make/chevrolet

theres several sizes of distributor shafts made for chevy engines.

cam materials vary

while your worrying about your new billet steel roller cam tearing up your old soft distributor gear, you might want to think about swapping to a bronze tip fuel pump push-rod to prevent excessive wear on that expensive billet steel cam core on the front end ,

taking the time to verify what your dealing with before ordering parts is going to save time and cash!

Its smart to file a small groove in the lower distributor so oil spray from the oil passage constantly lubricates the distributor gear to cam gar contact point

cast cores generally look cast like the lower cam while steel billet cores tend to appear to be machined and frequently have that copper coated finish

watch this

http://www.cpgnation.com/forum/properly ... -2519.html

Properly Matching Your COMP Cams® Camshaft & Distributor Gear

What Distributor Gear Should I Use With My Camshaft?

Matching camshaft and distributor gears is one of the most critical, yet often overlooked step in engine assembly. The proper distributor gear for your camshaft differs by both the material and the kind of lifter for which your camshaft was designed. Using the wrong material can lead to premature gear wear, possible camshaft wear and ultimately engine failure.

First off, no steel distributor gear is compatible with both flat tappet and hydraulic roller cams. This is because hydraulic rollers can be made from two possible materials and either of those materials requires a different gear than the flat tappet cam. Regardless, a steel gear is not compatible with a cast iron flat tappet cam.

Distributor Gear Materials:

1. Cast Iron

2. Composite (offers great life, conforms well to the mating cam gear, and is compatible with ANY camshaft gear material)

3. Melonized or hardened steel (material that OEMs use with factory roller cams; many aftermarket distributor manufacturers use these as the default gears for their distributors)

4. Bronze (conforms well to the mating camshaft gear and will not damage the camshaft gear, but it is a self sacrificing gear intended to be used in race applications only and should be replaced about once a year)

If you have a cast iron hydraulic or solid flat tappet cam, your distributor gear options are:

1. Cast iron distributor gear

2. Composite distributor gear

If you have an austempered ductile iron hydraulic or solid roller cam, your two options are:

1. Melonized or hardened steel distributor gear

2. Composite distributor gear

If you have a billet steel hydraulic or solid roller cam, your two options are:

1. Bronze distributor gear

2. Composite distributor gear

COMP Cams® recommends the composite gear because it is compatible with all camshaft gears – flat tappet, austempered cast iron cores, and billet cores. If the steel gear is not hardened, it is not compatible with either of the roller cam types.

Note: If you have an austempered core hydraulic roller cam and a .500†shaft distributor with a steel gear, verify with the manufacturer of the distributor that the steel gear they use is a melonized or hardened steel material and it will work fine.

billet cams can and do have steel distributor gears that are not compatible with stock cast iron or melonized stock distributor gears, so anytime you change cams get and correctly install the matching distributor gear

keep in mind theres a VAST difference in the QUALITY of bronze distributor gears and alloys vary wildly so its best to both use the cam manufacturers input during selecting components and not to assume all bronze gears are interchangeable

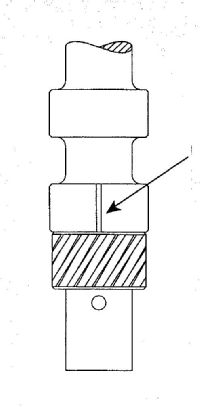

The bottom of a Chevrolet distributor housing can be modified to spray pressurized oil onto the distributor drive gear. The extra lubrication will reduce distributor gear and camshaft gear wear. This is especially important when the gear is used to drive non-standard accessories, such as a high volume oil pump, or a magneto that puts additional loads on it and the cam

as was previously pointed out,you must use the correct gear for the cam used,

Mark a straight-ahead position on the outside of the distributor body to use as a reference mark for the distributor’s placement in the engine. Use this orientation to position the oil groove. Remember that the cam is on the driver’s side of the distributor.

Crane suggests cutting a .030-inch-wide by .030-inch-deep slot in the lower band of the distributor housing to direct a spray of oil onto the camshaft and distributor gears. YOU can Use a Dremel tool to cut the slot into this distributor.

Thought I'd best add that you would be ahead by disassembling the distriburor first & clean the debris out before you re-assemble ,but you already know that

ITS just a tip for improving the oil flow to the distributor, GEARS TO PROMOTE LONGER LIFE,BUT it HELPS a good deal with cam/distributor gear life so its a STANDARD MOD I always do! (keep in mind youll want the grouve location to spray oil into the gear teeth contact area and that requires YOU to carefully match the notch location to the contact area WHEN the distributor is fully seated and timed correctly,

moving the distributor timing moves the oil spray pattern area so the time taken too CAREFULLY CUT a second shallow grouve in the block , on the lower band where the distributor seats and seal the oil passage as a secondary extra presureized oil spray source spraying oil onto the gear contact area,that can,t move seems like an even better IDEA . having twin high pressure oil jets spraying oil into the gears helps slow potential wear

HERE READ this link also

http://garage.grumpysperformance.com/index.php?threads/shiming-a-distributor.251/#post-299

http://www.summitracing.com/search/part-type/distributor-gears/make/chevrolet

theres several sizes of distributor shafts made for chevy engines.

cam materials vary

while your worrying about your new billet steel roller cam tearing up your old soft distributor gear, you might want to think about swapping to a bronze tip fuel pump push-rod to prevent excessive wear on that expensive billet steel cam core on the front end ,

taking the time to verify what your dealing with before ordering parts is going to save time and cash!

- 0.491 in.

- 0.500 in.

- 0.490 in.

- 0.427 in.

- ask detailed question's about your application at YOUR cam manufacturers tech support, desk.

- there are several materuials and sizes, match the wrong parts and it gets darn expensive real fast

- aluminum/bronze,

- Melonized Steel

- Composite, Carbon Ultra-Poly,

- Iron,

- steel,

Its smart to file a small groove in the lower distributor so oil spray from the oil passage constantly lubricates the distributor gear to cam gar contact point

cast cores generally look cast like the lower cam while steel billet cores tend to appear to be machined and frequently have that copper coated finish

watch this

http://www.cpgnation.com/forum/properly ... -2519.html

Properly Matching Your COMP Cams® Camshaft & Distributor Gear

What Distributor Gear Should I Use With My Camshaft?

Matching camshaft and distributor gears is one of the most critical, yet often overlooked step in engine assembly. The proper distributor gear for your camshaft differs by both the material and the kind of lifter for which your camshaft was designed. Using the wrong material can lead to premature gear wear, possible camshaft wear and ultimately engine failure.

First off, no steel distributor gear is compatible with both flat tappet and hydraulic roller cams. This is because hydraulic rollers can be made from two possible materials and either of those materials requires a different gear than the flat tappet cam. Regardless, a steel gear is not compatible with a cast iron flat tappet cam.

Distributor Gear Materials:

1. Cast Iron

2. Composite (offers great life, conforms well to the mating cam gear, and is compatible with ANY camshaft gear material)

3. Melonized or hardened steel (material that OEMs use with factory roller cams; many aftermarket distributor manufacturers use these as the default gears for their distributors)

4. Bronze (conforms well to the mating camshaft gear and will not damage the camshaft gear, but it is a self sacrificing gear intended to be used in race applications only and should be replaced about once a year)

If you have a cast iron hydraulic or solid flat tappet cam, your distributor gear options are:

1. Cast iron distributor gear

2. Composite distributor gear

If you have an austempered ductile iron hydraulic or solid roller cam, your two options are:

1. Melonized or hardened steel distributor gear

2. Composite distributor gear

If you have a billet steel hydraulic or solid roller cam, your two options are:

1. Bronze distributor gear

2. Composite distributor gear

COMP Cams® recommends the composite gear because it is compatible with all camshaft gears – flat tappet, austempered cast iron cores, and billet cores. If the steel gear is not hardened, it is not compatible with either of the roller cam types.

Note: If you have an austempered core hydraulic roller cam and a .500†shaft distributor with a steel gear, verify with the manufacturer of the distributor that the steel gear they use is a melonized or hardened steel material and it will work fine.

billet cams can and do have steel distributor gears that are not compatible with stock cast iron or melonized stock distributor gears, so anytime you change cams get and correctly install the matching distributor gear

keep in mind theres a VAST difference in the QUALITY of bronze distributor gears and alloys vary wildly so its best to both use the cam manufacturers input during selecting components and not to assume all bronze gears are interchangeable

The bottom of a Chevrolet distributor housing can be modified to spray pressurized oil onto the distributor drive gear. The extra lubrication will reduce distributor gear and camshaft gear wear. This is especially important when the gear is used to drive non-standard accessories, such as a high volume oil pump, or a magneto that puts additional loads on it and the cam

as was previously pointed out,you must use the correct gear for the cam used,

Mark a straight-ahead position on the outside of the distributor body to use as a reference mark for the distributor’s placement in the engine. Use this orientation to position the oil groove. Remember that the cam is on the driver’s side of the distributor.

Crane suggests cutting a .030-inch-wide by .030-inch-deep slot in the lower band of the distributor housing to direct a spray of oil onto the camshaft and distributor gears. YOU can Use a Dremel tool to cut the slot into this distributor.

Thought I'd best add that you would be ahead by disassembling the distriburor first & clean the debris out before you re-assemble ,but you already know that

ITS just a tip for improving the oil flow to the distributor, GEARS TO PROMOTE LONGER LIFE,BUT it HELPS a good deal with cam/distributor gear life so its a STANDARD MOD I always do! (keep in mind youll want the grouve location to spray oil into the gear teeth contact area and that requires YOU to carefully match the notch location to the contact area WHEN the distributor is fully seated and timed correctly,

moving the distributor timing moves the oil spray pattern area so the time taken too CAREFULLY CUT a second shallow grouve in the block , on the lower band where the distributor seats and seal the oil passage as a secondary extra presureized oil spray source spraying oil onto the gear contact area,that can,t move seems like an even better IDEA . having twin high pressure oil jets spraying oil into the gears helps slow potential wear

Last edited by a moderator: