hey grumpyvette ,

you still around? i would like to ask you about a small base circle cam.I just bought one and measured the lobes on it compared to my other cam which is a edelbrock HR 234/238 duration @ 50

and lift 539/548 ,the new cam is a extreme HR 242/240 duration @ 50,and the lift is 540/562.And the lobes seem to be a little smaller then the edelbrock cam,which is suppose to be smaller in duration. and lift.I don,t understand this unless it has something to do with small base circle cam.Its for stroker engines which you probably know already.I thought just the base circle of the cam would be smaller.Can you explain this to me? No body on CF could really answer it for me.

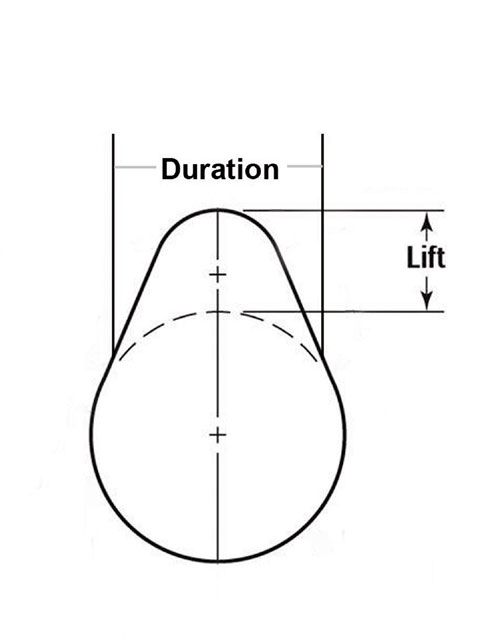

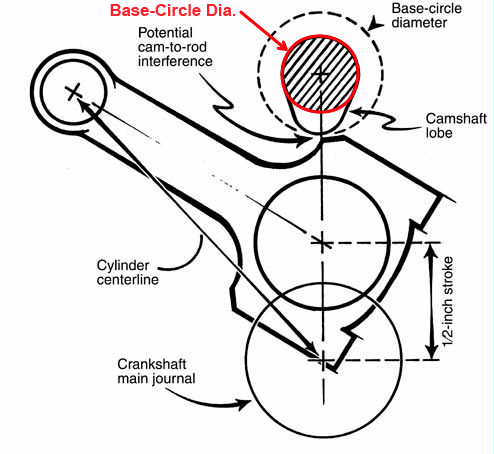

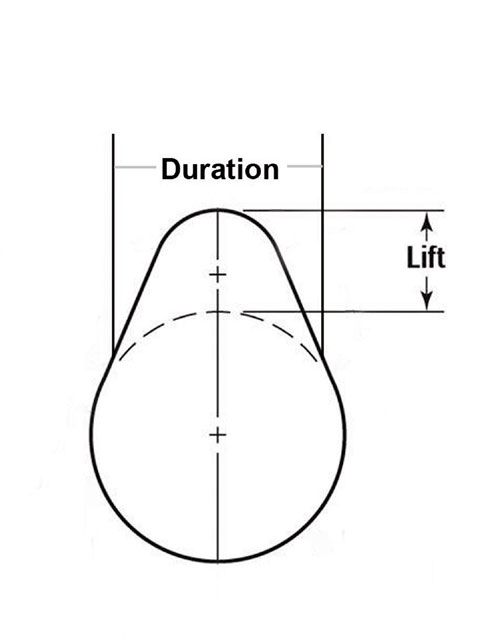

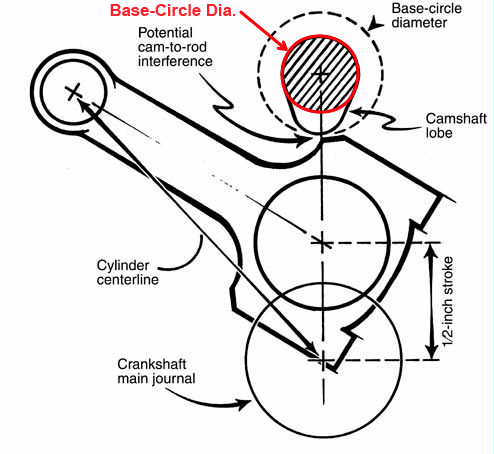

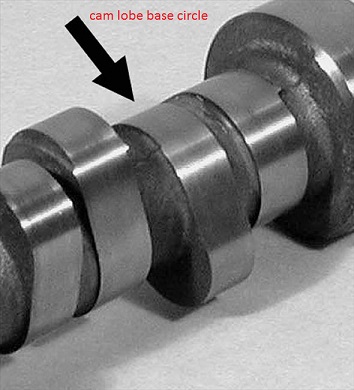

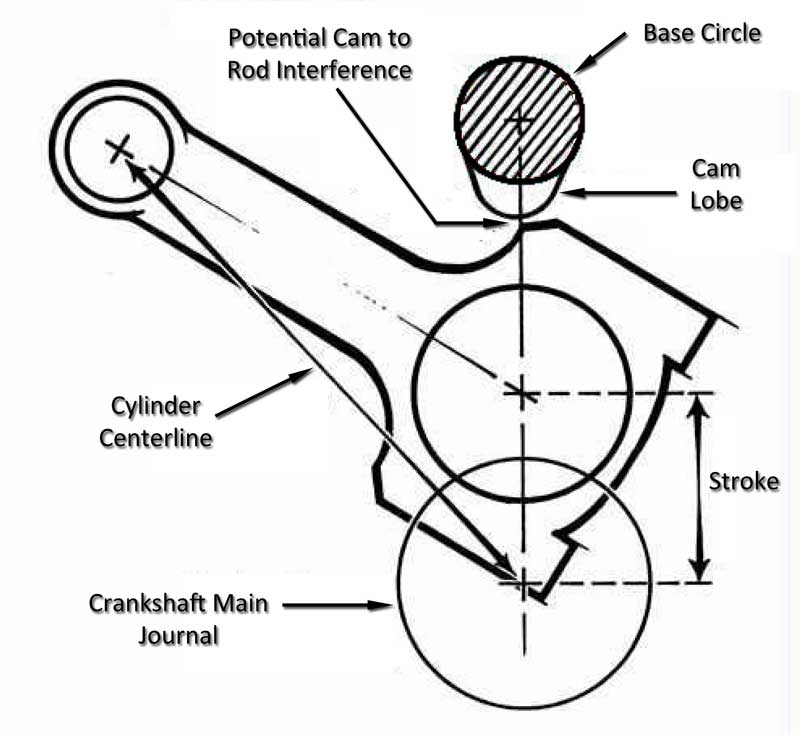

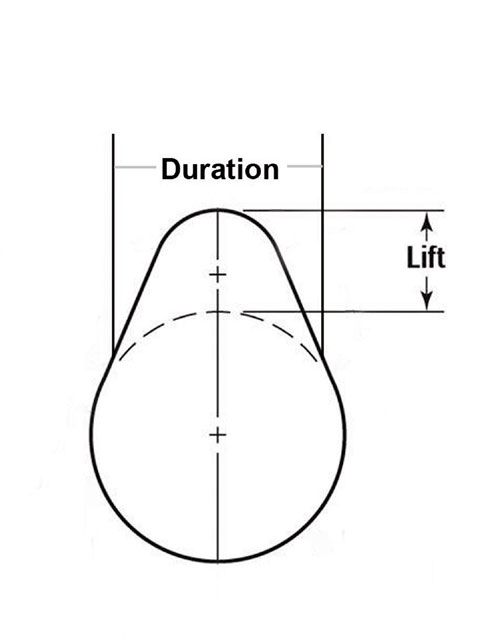

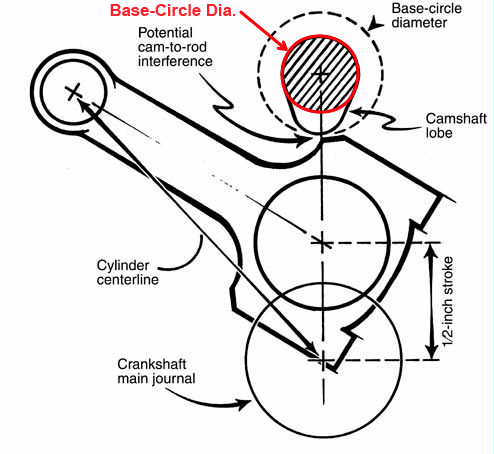

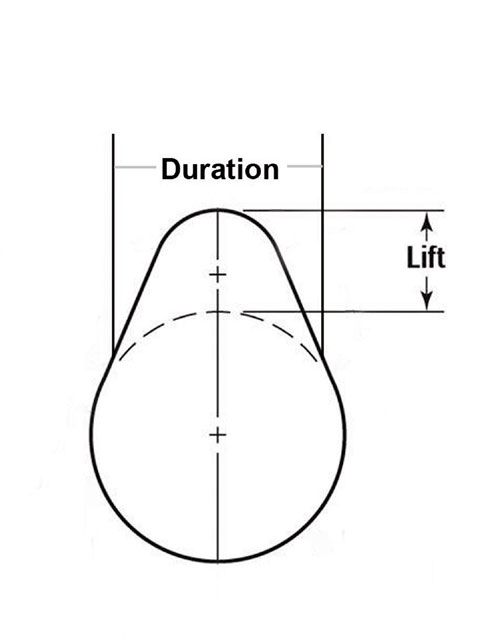

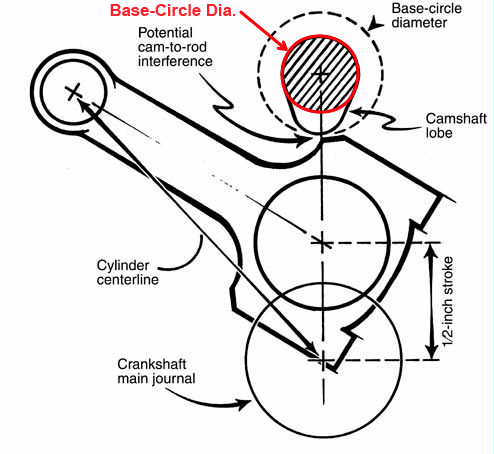

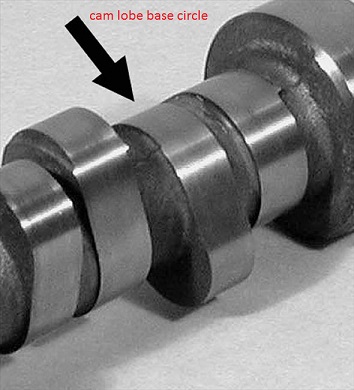

lift on the valve is controlled by the distance the lifter travels between the cams base circle to the peak lift on the cam lobe, small base cams lift the lifter the same distance as the standard cams, but the smaller base circle allows the cam lobes distance from the cams center-line to be less to provide more cam lobe to connecting rod clearance.

a small base cam may have a .900 inch base circle the standard cams will be closer to a 1.060 but several manufacturers use a 1.125" to 1.150" base circle. keep in mind theres several different cam core materials and heat treatments used by various manufacturers

your cams lift, is the result of the lifter movement, or distance it travels from the cams base circle, where the valves seated, to the point in the cams rotation where the lifters moved along the ramp surface fully up on the nose of the cam lobe where the valves at full lift.

example

lets say in this case we compare two imaginary cams

a standard cams base circle is 1.125" and

your cams running on a .900 base circle

both cams have a .560 valve lift and run with 1.5:1 rockers

so both cams will need to move the lifter .374"

that means the standard cam lobe will be 1.125"+.374" or 1.499" from the cams base to the cam lobe nose

that means the small base cam lobe will be .900"+.374" or 1.274" from the cams base to the cam lobe nose

which is significantly smaller,

small base circle cams are generally only used when connecting rod clearance necessitates there use

your correct, its the circle the cam lifter seats on when the lifters NOT on the lobe and the valves seated, but keep in mind the lobe lift will remain the same for a given valve lift, so reducing the distance from the rotational center-line of the cam to the base circle also reduces the diameter of the arc the cam lobe makes as it rotates, so reducing the base circle effectively reduces the diameter of the rotating cam, ,lobes nose, giving greater clearance to the rods and crank as they rotate, past each other.

when you go to a small base cam a billet core is almost mandatory

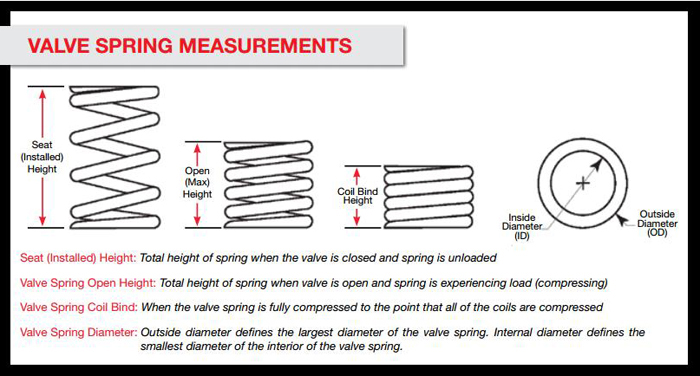

Base Circle, or the heel, is the round portion of the cam lobe. This is where the lifter rides while the valve is closed. A high spot in this area is called Base Circle Runout. If the runout is more than .001 on hydraulic lifter cams the valve will be off of its seat while the lifter is on the runout area. Poor performance and burnt valves will result from this. Small Base Circle Cams have the lobes ground down to the core diameter to give extra clearance for connecting rods used on stroker cranks. Higher lift cams also have smaller base circle diameters than stock lift cams.

Billets and Cores are the blank shafts that the camshafts are made from. Cast Cores and Proferal Iron Billets are used for most flat tappet camshafts. Steel Billets are used for roller tappet camshafts.

Ok i understand that ,so i only thing to make up the difference would be longer pushrod,right? I was thinking the lobe part of the cam that i want to run would be bigger then the old cam,and that that base circle was just the part of the cam that was smaller.Its the whole cam lobe thats smaller and you make up the difference with longer push rod.Is that right or am i still off?

yes its common for a longer push rod to be required but thats NOT always required, because in a few cases the rocker geometry allows you to just take up the clearance with the rocker adjustment on the rocker stud threads, but youll ALWAYS need to verify the geometry

greg_moreira posted this info

verify during pre-assembly that you lifters match the lifter bore and oil passage geometry,

the main issue, although even with a .900 base...most lifters are fine. The problem is if the oil "band" drops low enough in the lifter bore that it actually comes out the bottom and just allows oil to leak out into free space(not inside the lifter bore). That creates a pretty large internal leak/oil pressure drop.

Ive also heard reported that in some cases the band is located low enough that it doesnt line up well with the internal oil passages...thereby creating a restriction for other lifters in sequence.

Either way...its not something you wanna deal with(finding out what happens if the lifter is too short), but usually not a problem with a .900. I cant speak for all lifters out there...but the typical crower or isky lifters work well on a .900 without issue. There may be other brands that dont have as much luck just depending on where the band is. Easy to check though. Just put the lifter on the lobe at the base circle and see where it ends up!

comp sells a lifter that is stock height...but the band is moved to compensate for the smaller base circle. Not much of a fan of most of their stuff though. I like the pressurized oiling to the needle bearings as opposed to most of theirs which only directs oil to the sides of hte lifter wheel.

I've heard their highest end lifters now have oiling directly to the axle/needle bearings, but cant say for sure on that."

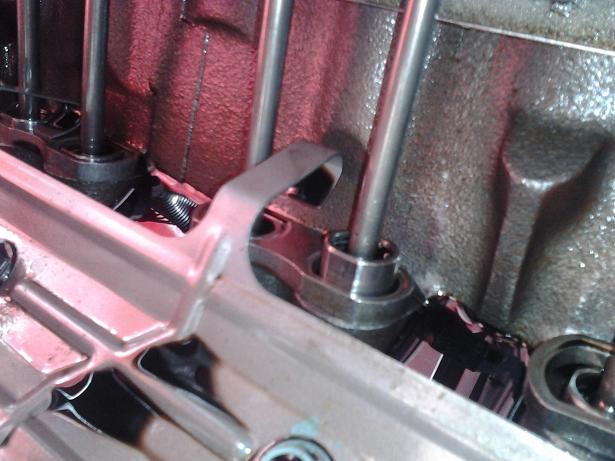

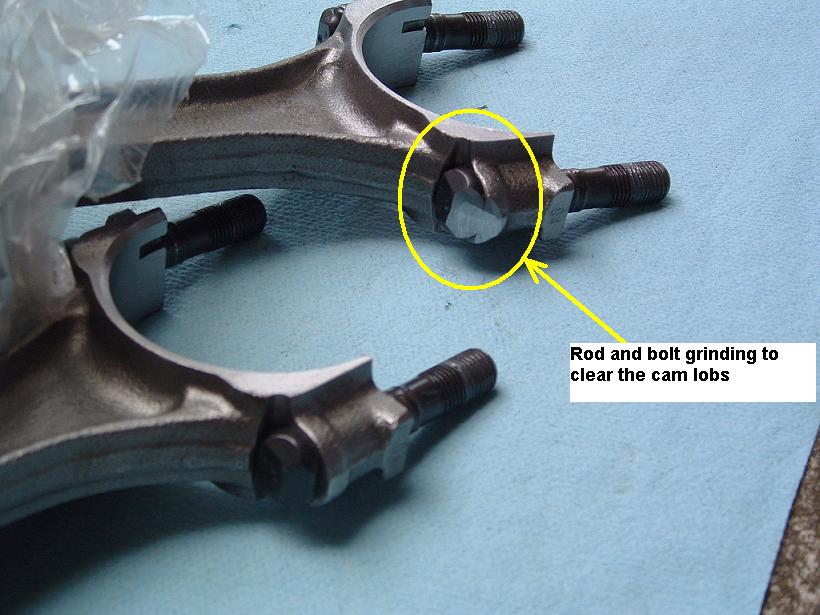

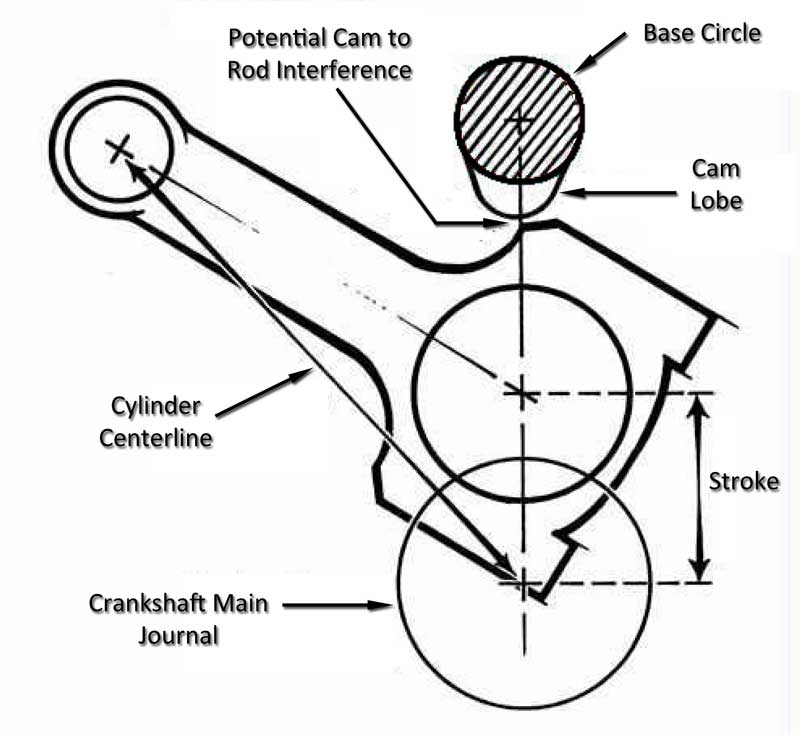

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

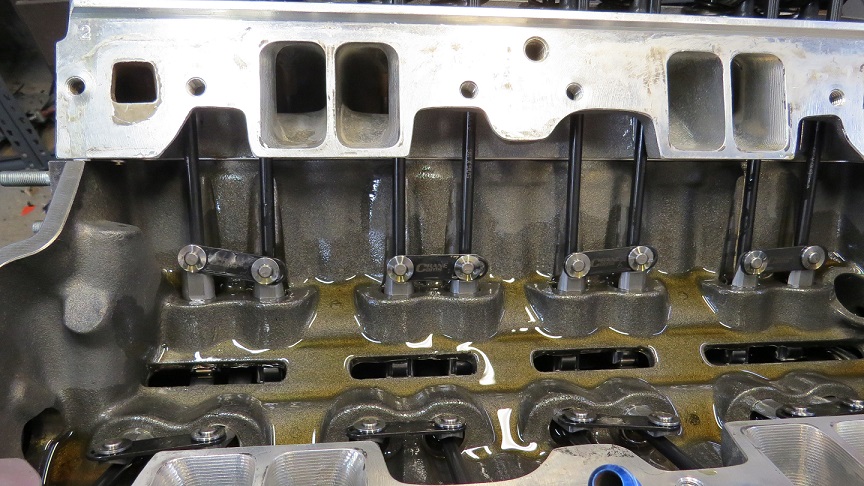

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

generally its a minor easily done clearance job

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

bits of related info you'll need

http://garage.grumpysperformance.com/index.php?threads/383-build-for-a-friend.14273/

https://www.jegs.com/tech-articles/camshaft-specification-basics.html

viewtopic.php?f=50&t=1249

viewtopic.php?f=52&t=181

viewtopic.php?f=50&t=428

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=2746

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=126

viewtopic.php?f=52&t=697

viewtopic.php?f=55&t=4590

viewtopic.php?f=44&t=700

viewtopic.php?f=69&t=519

you still around? i would like to ask you about a small base circle cam.I just bought one and measured the lobes on it compared to my other cam which is a edelbrock HR 234/238 duration @ 50

and lift 539/548 ,the new cam is a extreme HR 242/240 duration @ 50,and the lift is 540/562.And the lobes seem to be a little smaller then the edelbrock cam,which is suppose to be smaller in duration. and lift.I don,t understand this unless it has something to do with small base circle cam.Its for stroker engines which you probably know already.I thought just the base circle of the cam would be smaller.Can you explain this to me? No body on CF could really answer it for me.

lift on the valve is controlled by the distance the lifter travels between the cams base circle to the peak lift on the cam lobe, small base cams lift the lifter the same distance as the standard cams, but the smaller base circle allows the cam lobes distance from the cams center-line to be less to provide more cam lobe to connecting rod clearance.

a small base cam may have a .900 inch base circle the standard cams will be closer to a 1.060 but several manufacturers use a 1.125" to 1.150" base circle. keep in mind theres several different cam core materials and heat treatments used by various manufacturers

your cams lift, is the result of the lifter movement, or distance it travels from the cams base circle, where the valves seated, to the point in the cams rotation where the lifters moved along the ramp surface fully up on the nose of the cam lobe where the valves at full lift.

example

lets say in this case we compare two imaginary cams

a standard cams base circle is 1.125" and

your cams running on a .900 base circle

both cams have a .560 valve lift and run with 1.5:1 rockers

so both cams will need to move the lifter .374"

that means the standard cam lobe will be 1.125"+.374" or 1.499" from the cams base to the cam lobe nose

that means the small base cam lobe will be .900"+.374" or 1.274" from the cams base to the cam lobe nose

which is significantly smaller,

small base circle cams are generally only used when connecting rod clearance necessitates there use

your correct, its the circle the cam lifter seats on when the lifters NOT on the lobe and the valves seated, but keep in mind the lobe lift will remain the same for a given valve lift, so reducing the distance from the rotational center-line of the cam to the base circle also reduces the diameter of the arc the cam lobe makes as it rotates, so reducing the base circle effectively reduces the diameter of the rotating cam, ,lobes nose, giving greater clearance to the rods and crank as they rotate, past each other.

when you go to a small base cam a billet core is almost mandatory

Base Circle, or the heel, is the round portion of the cam lobe. This is where the lifter rides while the valve is closed. A high spot in this area is called Base Circle Runout. If the runout is more than .001 on hydraulic lifter cams the valve will be off of its seat while the lifter is on the runout area. Poor performance and burnt valves will result from this. Small Base Circle Cams have the lobes ground down to the core diameter to give extra clearance for connecting rods used on stroker cranks. Higher lift cams also have smaller base circle diameters than stock lift cams.

Billets and Cores are the blank shafts that the camshafts are made from. Cast Cores and Proferal Iron Billets are used for most flat tappet camshafts. Steel Billets are used for roller tappet camshafts.

Ok i understand that ,so i only thing to make up the difference would be longer pushrod,right? I was thinking the lobe part of the cam that i want to run would be bigger then the old cam,and that that base circle was just the part of the cam that was smaller.Its the whole cam lobe thats smaller and you make up the difference with longer push rod.Is that right or am i still off?

yes its common for a longer push rod to be required but thats NOT always required, because in a few cases the rocker geometry allows you to just take up the clearance with the rocker adjustment on the rocker stud threads, but youll ALWAYS need to verify the geometry

greg_moreira posted this info

verify during pre-assembly that you lifters match the lifter bore and oil passage geometry,

the main issue, although even with a .900 base...most lifters are fine. The problem is if the oil "band" drops low enough in the lifter bore that it actually comes out the bottom and just allows oil to leak out into free space(not inside the lifter bore). That creates a pretty large internal leak/oil pressure drop.

Ive also heard reported that in some cases the band is located low enough that it doesnt line up well with the internal oil passages...thereby creating a restriction for other lifters in sequence.

Either way...its not something you wanna deal with(finding out what happens if the lifter is too short), but usually not a problem with a .900. I cant speak for all lifters out there...but the typical crower or isky lifters work well on a .900 without issue. There may be other brands that dont have as much luck just depending on where the band is. Easy to check though. Just put the lifter on the lobe at the base circle and see where it ends up!

comp sells a lifter that is stock height...but the band is moved to compensate for the smaller base circle. Not much of a fan of most of their stuff though. I like the pressurized oiling to the needle bearings as opposed to most of theirs which only directs oil to the sides of hte lifter wheel.

I've heard their highest end lifters now have oiling directly to the axle/needle bearings, but cant say for sure on that."

rods that use bolts with nuts like pictured below will be weakened if excessively clearance ground

stroker profile rods offer more clearance to cam lobes, and yes the stroker clearanced profile rods are available in both (h) and (I ) beam designs

generally its a minor easily done clearance job

if you wonder why I suggest using SCAT (H) beam style cap screw connecting rods vs stock or most (I) beam designs this picture should show the increased cam to connecting rod clearance

bits of related info you'll need

http://garage.grumpysperformance.com/index.php?threads/383-build-for-a-friend.14273/

https://www.jegs.com/tech-articles/camshaft-specification-basics.html

viewtopic.php?f=50&t=1249

viewtopic.php?f=52&t=181

viewtopic.php?f=50&t=428

viewtopic.php?f=44&t=38

viewtopic.php?f=52&t=2746

viewtopic.php?f=52&t=1376

viewtopic.php?f=52&t=126

viewtopic.php?f=52&t=697

viewtopic.php?f=55&t=4590

viewtopic.php?f=44&t=700

viewtopic.php?f=69&t=519

Last edited by a moderator: