larrym

Member

so it begins........

Motors out and partially tore down done need a puller then I can get the front cover off, it was time!

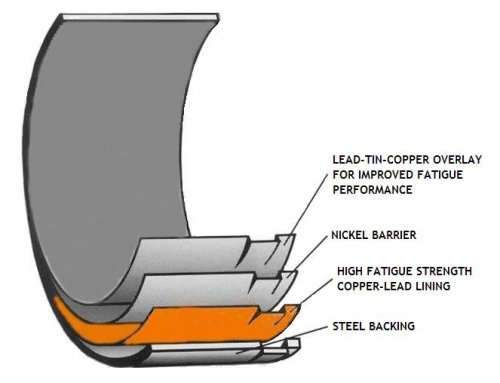

Pulled one rod bearing no copper, hope I can get away with a polish only on the crank machine shop will assess once I drop it off.

Here are some pics.

http://photoshare.shaw.ca/messages/view ... page/1/15/

Motors out and partially tore down done need a puller then I can get the front cover off, it was time!

Pulled one rod bearing no copper, hope I can get away with a polish only on the crank machine shop will assess once I drop it off.

Here are some pics.

http://photoshare.shaw.ca/messages/view ... page/1/15/