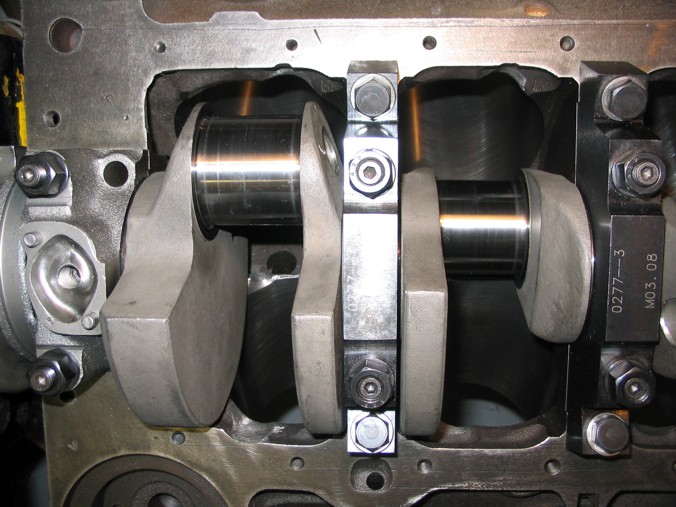

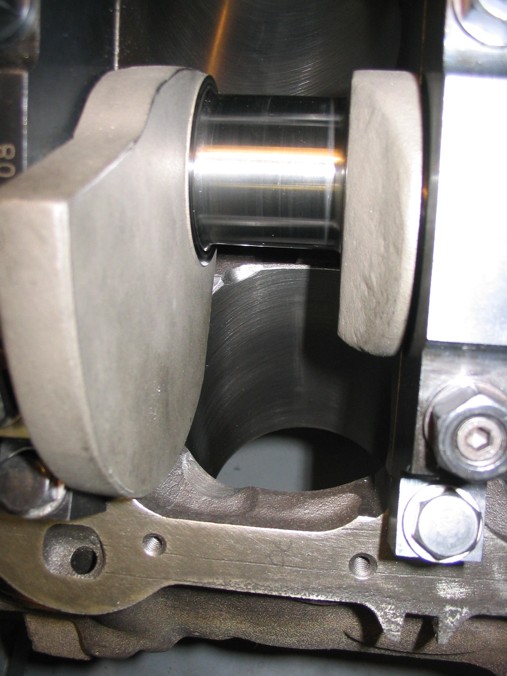

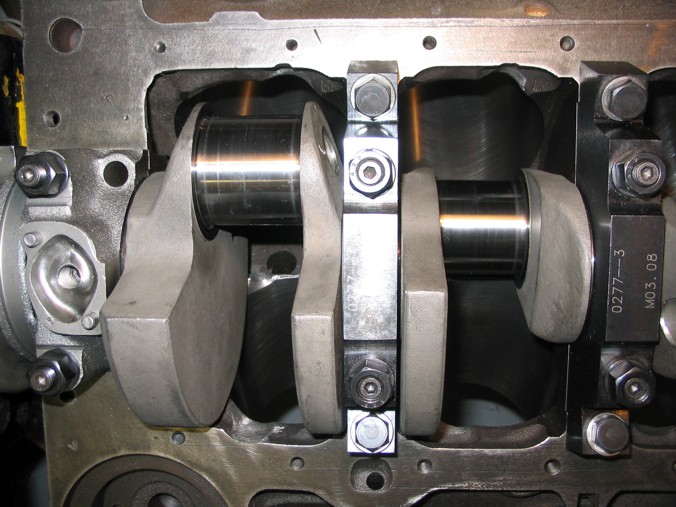

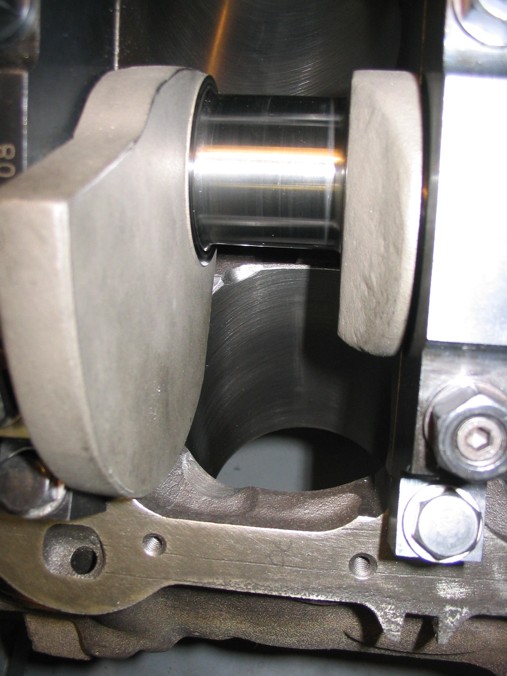

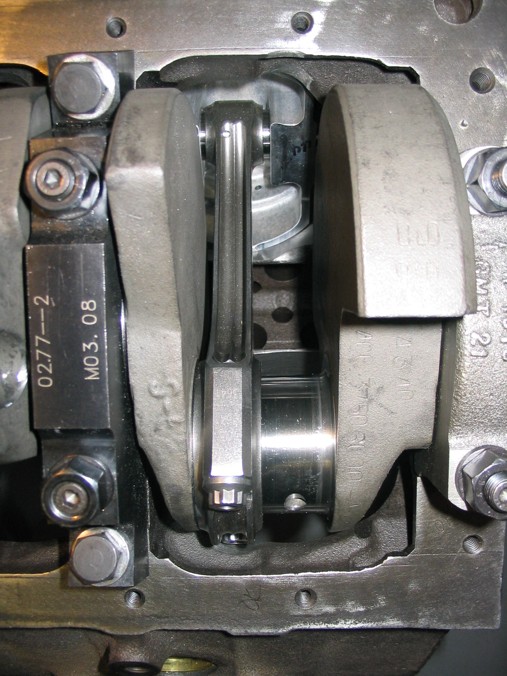

place a single rod/piston assembly with well oiled bearings and no rings installed on the first cylinders journal, and have the cam installed to check clearances ,now, rotate the crank thru a couple full rotations so the piston slides freely in the oiled bore, while you look closely at the rod too block clearance and rod too cam lobe clearance, if the cam lobes too close the edge of the rod bolt upper/edge of the bolt or rod itself needs to be filed/ground for clearance since you can,t grind the cam lobe, on the block the block gets clearanced ground, you want about a .060 minimum clearance. a large paper clip can be used as a crude feeler gauge,

a 1/2" dia carbide cutting burr in a die grinder can do it in seconds,once that's done you move that piston & rod to the next cylinder and repeat 7 more times, etc. don,t forget to clean up after wards, and DON,T forget the rod and piston has the exhaust/intake valve and rod bearing radius fit correctly in only one direction on that cylinder

WORTH READING

AFTER

Small Chevy

Fastener Type Torque Spec

7/16 in. outer main cap bolt 65 ft.-lbs.

7/16 in. inner main cap bolt 70 ft.-lbs.

3/8 in. outer main cap bolt 40 ft.-lbs.

11/32 in. connecting rod bolt 38-44 ft.-lbs.

3/8 in. connecting rod bolt 40-45 ft.-lbs.

Cylinder head bolts 65 ft.-lbs.

Screw-in rocker arm studs 50 ft.-lbs.

Intake manifold bolts (cast iron heads) 30 ft.-lbs.

Oil pump bolt 60-70 ft.-lbs.

Cam sprocket bolts 18-20 ft.-lbs.

Harmonic damper bolt 60 ft.-lbs.

Flywheel/Flexplate bolts 65 ft.-lbs.

Pressure plate bolts 35 ft.-lbs.

Bell housing bolts 25 ft.-lbs.

Exhaust manifold bolts 25 ft.-lbs.

Big Chevy

Fastener Type Torque Specs

Main cap bolt, 396-427 2-bolt 95 ft.-lbs.

Main cap bolt, 396-454 4-bolt (inner/outer) 110 ft.-lbs.

3/8 in. connecting rod bolt 50 ft.-lbs.

7/16 in. connecting rod bolt 67-73 ft.-lbs.

Cylinder head bolts, long 75 ft.-lbs.

Cylinder head bolts, short 65-68 ft.-lbs.

Screw-in rocker arm studs 50 ft.-lbs.

Intake manifold bolts (cast iron head) 25 ft.-lbs.

Oil pump bolt 65 ft.-lbs.

Cam sprocket bolts 20 ft.-lbs.

Harmonic damper bolt 85 ft.-lbs.

Flywheel/Flexplate bolts 60 ft.-lbs.

Pressure plate bolts 35 ft.-lbs.

Bell housing bolts 25 ft.-lbs.

Exhaust manifold bolts 20 ft.-lbs.

http://www.fourwheeler.com/techarticles ... to_11.html

IF your going to use ARP main cap studs THE TORQUE SETTINGS ARE DIFFERENT than the original BOLTS, the STUDS ARE STRONGER, BUT,you might also consider that main studs generally install after cleaning the threads in the block with a tap,blowing them dry with high pressure air, oiling the studs course threads with the thread sealant and fine threads end with the ARP thread lube, when you screw them into the block the full thread depth,by hand, then get backed out one turn, the main caps installed and the nuts torqued in stages to seat and hold the main caps, now LOOK at those STUDS the end in the block threads is SAE COURSE thread, the end your torquing the nut on is SAE FINE THREAD with a much different PITCH that requires less tq to give the same clamp loads

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

http://www.arp-bolts.com/catalog/Catalog.html

Why do they get backed out by one turn? I'm trying to think of the physics behind it, but I can't think of any good reason. What is the physics answer, Grumpy?

the threads must bear evenly and align correctly with the studs centerline, for the stud to apply max loads over the total threaded surface ,the threaded section must be under tension alone and engage the total threaded surface in the block, if the stud is torqued into place, youve preloaded the threads bearing the load and they are partly under compressive loads ,your basically jacking the bottom of the threaded hole away from the threaded section, and applying THOUSANDS of lbs of extra stress to the blocks web area if you torque the threads to the same 100 ft lbs the original bolts were tightened to, the threads in the block will now have added stress once the full tension loads on the studs and main caps is applied by torqing the nuts on the studs ,theres added stress on the block, if the studs have bottomed out and are pushing on the bottom of the threaded hole making the block web area more likely to crack or the crank saddles to distort.

keep in mind FACTORY BOLTS are made slightly shorter to PREVENT the bolt tip bottoming out in the hole, but bolts cause wear on the threads because they are tightened while the bolts still advancing deeper into the threaded block, studs cause far less wear because they fully engage the threads bearing the loads before the tensive load is applied

heres what ARP says

"STUDS vs. BOLTS

ARP recommends the use of main studs over bolts whenever possible for several key reasons. First is the ability to obtain more accurate torque readings because studs don’t “twist†into the block. All clamping forces are on one axis. By the same token, there is less force exerted on the block threads, which contributes to improved block life (very critical on aluminum blocks). Finally, there are factors of easier engine assembly and proper alignment of caps every time"

ARP's instructions (for head studs)state that you should thread the studs into the block until they're hand-tight, but with the head on the block, this is difficult. Fortunately, ARP was thoughtful enough to incorporate a fitting for an Allen wrench into the head of each stud. So, using an Allen wrench, I threaded the studs into the head until I could no longer turn the wrench with two fingers. This method seems to have worked nicely

1. Clean and chase appropriate threads in

block to ensure proper thread engagement

and accurate torque readings.

2. All hardware (and caps) should be

cleaned and inspected prior to installation,

looking for any shipping damage or defects.

3. Screw studs into block, finger tight

ONLY. For permanent installation, apply

Loc-tite (or similar adhesive) sparingly

to threads. Be sure and install the caps

promptly before the cement sets to prevent

misalignment of studs in block.

1. Clean and chase appropriate threads in

block to ensure proper thread engagement

and accurate torque readings.

2. All hardware (and caps) should be

cleaned and inspected prior to installation,

looking for any shipping damage or defects.

There are a number of important considerations

when installing ARP main studs.

3. Screw studs into block, finger tight

ONLY. For permanent installation, apply

Loc-tite (or similar adhesive) sparingly

to threads. Be sure and install the caps

promptly before the cement sets to prevent

misalignment of studs in block.

First and foremost is making sure the

block and studs are as clean as possible.

Foreign matter and debris can easily affect

the quality of thread engagement and

cause erroneous torque readings. Do not

re-cut threads in the block – use the special

“chaser†taps as listed on page 87 of this catalog.

This will preserve the integrity of the

threads and provide better engagement.

Calibrate your torque wrench – even new

wrenches have been known to be off by as

much as 10 foot pounds! Use consistent

tightening techniques.

4. Install main caps, checking for binding

and misalignment. Lubricate threads, nuts

and washers with oil or ARP moly assembly

lubricant before installation. Note that torque

specs will vary by lubricant. Moly lube is

most consistent. Have block align honed.

5. Using the instructions provided with

the studs, tighten the nuts to proper

torque values three times. NOTE: If using

Loc-Tite or similar cement, proper preload

must be achieved prior to it setting up.

http://www.arp-bolts.com/FAQ/FAQ.html

I usually use this sealant (sparingly)on the course ends of main cap studs that screw in hand tight, and ESPECIALLY on head studs that enter water jackets

http://www.permatex.com/products/Au.../Permatex_Super_300_Form-A-Gasket_Sealant.htm

keep in mind the course thread section is not being screwed in or the threads moved as the nut on the fine thread upper end is torqued to spec. and that thread requires the ARP thread lubricant to get the correct stretch and that stud needs to be cycled up to full torqure then released and retorqued,a minimum of three times to get the stretch/tq correct

I got asked recently what hydrolic roller cam ID suggest for a street/strip 383 combo?(obviously theres a wide sellection that may work,)

ONE GENTELMAN pointed out ,after shopping around one of the least expensive deals seems to be the EDELBROCK CAM BELOW

http://www.jegs.com/i/Edelbrock/350/22015/10002/-1#

SB-Chevy 283-400 Hydraulic Roller Camshaft Kit

Duration Advertised 296° Intake/300° Exhaust

Duration @ .050'' 234° Intake/238° Exhaust

Lift @ Valve .539'' Intake/.548'' Exhaust

Lift @ Cam .359'' Intake/.365'' Exhaust

Lobe Separation Angle 112°

Intake Centerline 107°

Intake Timing @ .050" Open 10° BTDC

Close 44° ABDC

Exhaust Timing @ .050" Open 56° BBDC

Close 2° ATDC

IVE used similar cam designs (durration/lift/)in the past with excellent results and $709 for the cam, roller lifters and pushrods is a good value, naturally the REST of the components and the cars drive train and the cars intended use will effect the choice

the only thing that makes me hesitate is the quality of edelbrocks cam cores.AS most IVE SEEN are not billet but cast cores which are less durable and on a 383, PLUS you want a small base circle cam......for rotating assembly clearance issues ,one reason I usually suggest this cam in similar combos

http://www.cranecams.com/index.php?show=browseParts&action=partSpec&partNumber=119661&lvl=2&prt=5

http://www.jegs.com/i/Crane/270/119661/10002/-1#

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&N=0&Ntt=11532-16&Ntk=all&Nty=1&D=11532-16&Ntx=mode+matchallany&Dx=mode+matchallany&searchTerm=11532-16

Grind Number: HR-230/359-2S-12.90 IG

Operating Range: 3000-6500 RPM

Duration Advertised: 292° Intake / 300° Exhaust

Duration @ .050'' Lift: 230° Intake / 238° Exhaust

Valve Lift w/1.5 Rockers: .539'' Intake / .558'' Exhaust

Lobe Separation Angle: 112°

Max Lift Angle: 107° ATDC Intake / 117° BTDC Exhaust

Open/Close @.050'' Cam Lift: Intake - 8° BTDC (opens) / 42° ABDC (closes)

Exhaust - 56° BBDC (opens) / 2° ATDC (closes)

with either cam youll want a 3000rpm stall converter , about 10.5:1 cpr and a 3.73-4.11:1 rear gear to maximize the preformance and a low restriction exhaust, headers and a high flow intake

IM currently running the crane 119661 cam in MY 383 and Ive tested over a dozen cams in that engine, so if its a street/strip combo ID suggest going that route, SMALL BASE CIRCLE AND BILLET CORE.....yeah! YOU GET WHAT YOU PAY,FOR and DURABILITY FOR PARTS TENDS TO COST MORE

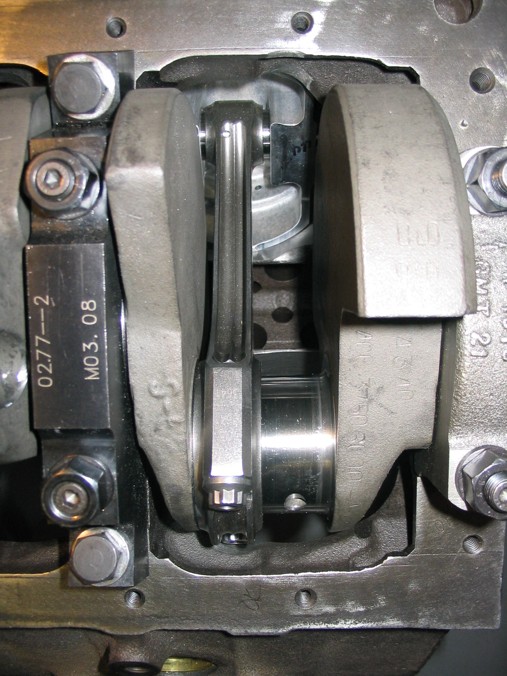

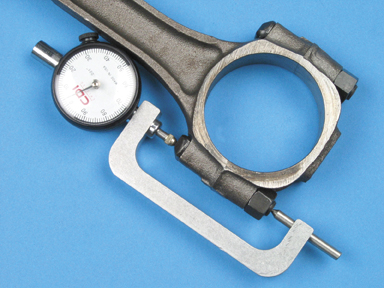

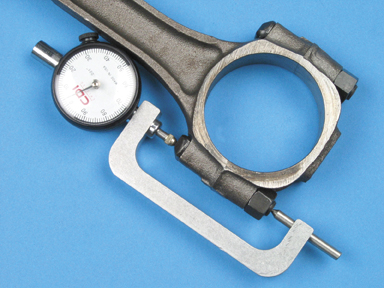

GOSFAST posted this great photo to illustrate the differance between rod designs

http://www.scatcrankshafts.com/index.htm

rods designed like the 3 SERIES generally won,t work with stroker cranks while the 2 series usually will

the connecting rods you sellect make a huge differance in the rod to cam lobe clearance, even a small base cam won,t clear some designs, it should be obvious that the connecting rod with the thru bolt has a great deal less cam lobe clearance potentially than the cap screw design next to it., and the cap screw rod probably clears the blocks oil pan rail area easier also.

Im running that crane 119661 cam retarded 4 degrees BTW but detonation has not been a problem, remember that the coolant temp, air temps the engine sees, QUENCH distance, type of head gasket and its construction ,ignition advance,plug heat range,piston to bore clearance, exhaust valve seat width, and oil temp and pollishing your combustion chamber and piston domes, and your AIR/FUEL RATIO , and the effective DYNAMIC compression ratio, have a noticable effect on detonation

and if you do see detonation, theres octane boosters like TOULUENE

http://www.gnttype.org/techarea/misc/octanebooster.html

http://www.team.net/sol/tech/octane_b.html

http://www.elektro.com/~audi/audi/toluene.html

MORE USEFUL INFO

viewtopic.php?f=50&t=1249

ASSUMING your ignition curves correct and your running the correct clearances and KEEPING THE COOLANT TEMP ,in the 190F-200F range and OIL TEMP. in the 190F-215F ranges, if you do a compression check and the PSI reading is above about 200 psi your going to more than likely need an octane booster to avoid detonation problems, if its around 200psi , you can usually get by on 92 octane high test gas, and if its BELOW about 180 psi you can probably use regular octane gas

a 1/2" dia carbide cutting burr in a die grinder can do it in seconds,once that's done you move that piston & rod to the next cylinder and repeat 7 more times, etc. don,t forget to clean up after wards, and DON,T forget the rod and piston has the exhaust/intake valve and rod bearing radius fit correctly in only one direction on that cylinder

383, do you clearance the 350 block, machine the crank, or both?

I hate to start a new thread when it seems that grumpy has exhaustively covered EVERYTHING when it comes to blocks and engine buildings already on this site, but this is sort of a specific question: I have been following a step by step on prepping my block to become a 383 build, and I am...

garage.grumpysperformance.com

AFTER

Small Chevy

Fastener Type Torque Spec

7/16 in. outer main cap bolt 65 ft.-lbs.

7/16 in. inner main cap bolt 70 ft.-lbs.

3/8 in. outer main cap bolt 40 ft.-lbs.

11/32 in. connecting rod bolt 38-44 ft.-lbs.

3/8 in. connecting rod bolt 40-45 ft.-lbs.

Cylinder head bolts 65 ft.-lbs.

Screw-in rocker arm studs 50 ft.-lbs.

Intake manifold bolts (cast iron heads) 30 ft.-lbs.

Oil pump bolt 60-70 ft.-lbs.

Cam sprocket bolts 18-20 ft.-lbs.

Harmonic damper bolt 60 ft.-lbs.

Flywheel/Flexplate bolts 65 ft.-lbs.

Pressure plate bolts 35 ft.-lbs.

Bell housing bolts 25 ft.-lbs.

Exhaust manifold bolts 25 ft.-lbs.

Big Chevy

Fastener Type Torque Specs

Main cap bolt, 396-427 2-bolt 95 ft.-lbs.

Main cap bolt, 396-454 4-bolt (inner/outer) 110 ft.-lbs.

3/8 in. connecting rod bolt 50 ft.-lbs.

7/16 in. connecting rod bolt 67-73 ft.-lbs.

Cylinder head bolts, long 75 ft.-lbs.

Cylinder head bolts, short 65-68 ft.-lbs.

Screw-in rocker arm studs 50 ft.-lbs.

Intake manifold bolts (cast iron head) 25 ft.-lbs.

Oil pump bolt 65 ft.-lbs.

Cam sprocket bolts 20 ft.-lbs.

Harmonic damper bolt 85 ft.-lbs.

Flywheel/Flexplate bolts 60 ft.-lbs.

Pressure plate bolts 35 ft.-lbs.

Bell housing bolts 25 ft.-lbs.

Exhaust manifold bolts 20 ft.-lbs.

http://www.fourwheeler.com/techarticles ... to_11.html

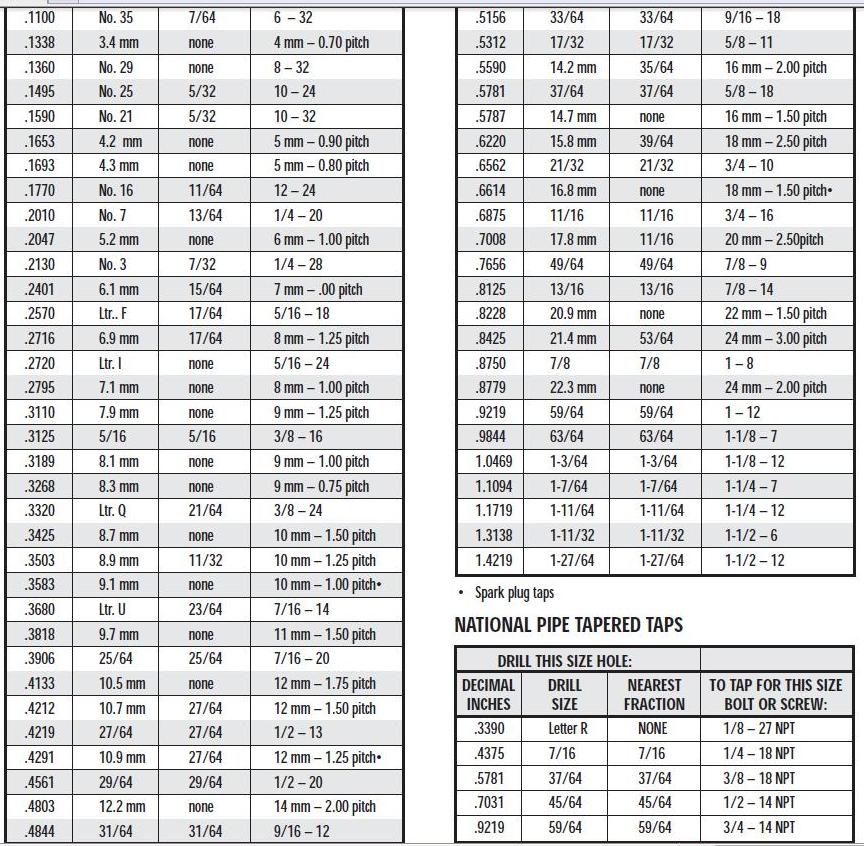

IF your going to use ARP main cap studs THE TORQUE SETTINGS ARE DIFFERENT than the original BOLTS, the STUDS ARE STRONGER, BUT,you might also consider that main studs generally install after cleaning the threads in the block with a tap,blowing them dry with high pressure air, oiling the studs course threads with the thread sealant and fine threads end with the ARP thread lube, when you screw them into the block the full thread depth,by hand, then get backed out one turn, the main caps installed and the nuts torqued in stages to seat and hold the main caps, now LOOK at those STUDS the end in the block threads is SAE COURSE thread, the end your torquing the nut on is SAE FINE THREAD with a much different PITCH that requires less tq to give the same clamp loads

http://www.imperialinc.com/pdf/I_Tap&DieChart.pdf

http://www.arp-bolts.com/catalog/Catalog.html

Why do they get backed out by one turn? I'm trying to think of the physics behind it, but I can't think of any good reason. What is the physics answer, Grumpy?

the threads must bear evenly and align correctly with the studs centerline, for the stud to apply max loads over the total threaded surface ,the threaded section must be under tension alone and engage the total threaded surface in the block, if the stud is torqued into place, youve preloaded the threads bearing the load and they are partly under compressive loads ,your basically jacking the bottom of the threaded hole away from the threaded section, and applying THOUSANDS of lbs of extra stress to the blocks web area if you torque the threads to the same 100 ft lbs the original bolts were tightened to, the threads in the block will now have added stress once the full tension loads on the studs and main caps is applied by torqing the nuts on the studs ,theres added stress on the block, if the studs have bottomed out and are pushing on the bottom of the threaded hole making the block web area more likely to crack or the crank saddles to distort.

keep in mind FACTORY BOLTS are made slightly shorter to PREVENT the bolt tip bottoming out in the hole, but bolts cause wear on the threads because they are tightened while the bolts still advancing deeper into the threaded block, studs cause far less wear because they fully engage the threads bearing the loads before the tensive load is applied

heres what ARP says

"STUDS vs. BOLTS

ARP recommends the use of main studs over bolts whenever possible for several key reasons. First is the ability to obtain more accurate torque readings because studs don’t “twist†into the block. All clamping forces are on one axis. By the same token, there is less force exerted on the block threads, which contributes to improved block life (very critical on aluminum blocks). Finally, there are factors of easier engine assembly and proper alignment of caps every time"

ARP's instructions (for head studs)state that you should thread the studs into the block until they're hand-tight, but with the head on the block, this is difficult. Fortunately, ARP was thoughtful enough to incorporate a fitting for an Allen wrench into the head of each stud. So, using an Allen wrench, I threaded the studs into the head until I could no longer turn the wrench with two fingers. This method seems to have worked nicely

1. Clean and chase appropriate threads in

block to ensure proper thread engagement

and accurate torque readings.

2. All hardware (and caps) should be

cleaned and inspected prior to installation,

looking for any shipping damage or defects.

3. Screw studs into block, finger tight

ONLY. For permanent installation, apply

Loc-tite (or similar adhesive) sparingly

to threads. Be sure and install the caps

promptly before the cement sets to prevent

misalignment of studs in block.

1. Clean and chase appropriate threads in

block to ensure proper thread engagement

and accurate torque readings.

2. All hardware (and caps) should be

cleaned and inspected prior to installation,

looking for any shipping damage or defects.

There are a number of important considerations

when installing ARP main studs.

3. Screw studs into block, finger tight

ONLY. For permanent installation, apply

Loc-tite (or similar adhesive) sparingly

to threads. Be sure and install the caps

promptly before the cement sets to prevent

misalignment of studs in block.

First and foremost is making sure the

block and studs are as clean as possible.

Foreign matter and debris can easily affect

the quality of thread engagement and

cause erroneous torque readings. Do not

re-cut threads in the block – use the special

“chaser†taps as listed on page 87 of this catalog.

This will preserve the integrity of the

threads and provide better engagement.

Calibrate your torque wrench – even new

wrenches have been known to be off by as

much as 10 foot pounds! Use consistent

tightening techniques.

4. Install main caps, checking for binding

and misalignment. Lubricate threads, nuts

and washers with oil or ARP moly assembly

lubricant before installation. Note that torque

specs will vary by lubricant. Moly lube is

most consistent. Have block align honed.

5. Using the instructions provided with

the studs, tighten the nuts to proper

torque values three times. NOTE: If using

Loc-Tite or similar cement, proper preload

must be achieved prior to it setting up.

http://www.arp-bolts.com/FAQ/FAQ.html

I usually use this sealant (sparingly)on the course ends of main cap studs that screw in hand tight, and ESPECIALLY on head studs that enter water jackets

http://www.permatex.com/products/Au.../Permatex_Super_300_Form-A-Gasket_Sealant.htm

keep in mind the course thread section is not being screwed in or the threads moved as the nut on the fine thread upper end is torqued to spec. and that thread requires the ARP thread lubricant to get the correct stretch and that stud needs to be cycled up to full torqure then released and retorqued,a minimum of three times to get the stretch/tq correct

I got asked recently what hydrolic roller cam ID suggest for a street/strip 383 combo?(obviously theres a wide sellection that may work,)

ONE GENTELMAN pointed out ,after shopping around one of the least expensive deals seems to be the EDELBROCK CAM BELOW

http://www.jegs.com/i/Edelbrock/350/22015/10002/-1#

SB-Chevy 283-400 Hydraulic Roller Camshaft Kit

Duration Advertised 296° Intake/300° Exhaust

Duration @ .050'' 234° Intake/238° Exhaust

Lift @ Valve .539'' Intake/.548'' Exhaust

Lift @ Cam .359'' Intake/.365'' Exhaust

Lobe Separation Angle 112°

Intake Centerline 107°

Intake Timing @ .050" Open 10° BTDC

Close 44° ABDC

Exhaust Timing @ .050" Open 56° BBDC

Close 2° ATDC

IVE used similar cam designs (durration/lift/)in the past with excellent results and $709 for the cam, roller lifters and pushrods is a good value, naturally the REST of the components and the cars drive train and the cars intended use will effect the choice

the only thing that makes me hesitate is the quality of edelbrocks cam cores.AS most IVE SEEN are not billet but cast cores which are less durable and on a 383, PLUS you want a small base circle cam......for rotating assembly clearance issues ,one reason I usually suggest this cam in similar combos

http://www.cranecams.com/index.php?show=browseParts&action=partSpec&partNumber=119661&lvl=2&prt=5

http://www.jegs.com/i/Crane/270/119661/10002/-1#

http://www.jegs.com/webapp/wcs/stores/servlet/KeywordSearchCmd?storeId=10001&catalogId=10002&langId=-1&N=0&Ntt=11532-16&Ntk=all&Nty=1&D=11532-16&Ntx=mode+matchallany&Dx=mode+matchallany&searchTerm=11532-16

Grind Number: HR-230/359-2S-12.90 IG

Operating Range: 3000-6500 RPM

Duration Advertised: 292° Intake / 300° Exhaust

Duration @ .050'' Lift: 230° Intake / 238° Exhaust

Valve Lift w/1.5 Rockers: .539'' Intake / .558'' Exhaust

Lobe Separation Angle: 112°

Max Lift Angle: 107° ATDC Intake / 117° BTDC Exhaust

Open/Close @.050'' Cam Lift: Intake - 8° BTDC (opens) / 42° ABDC (closes)

Exhaust - 56° BBDC (opens) / 2° ATDC (closes)

with either cam youll want a 3000rpm stall converter , about 10.5:1 cpr and a 3.73-4.11:1 rear gear to maximize the preformance and a low restriction exhaust, headers and a high flow intake

IM currently running the crane 119661 cam in MY 383 and Ive tested over a dozen cams in that engine, so if its a street/strip combo ID suggest going that route, SMALL BASE CIRCLE AND BILLET CORE.....yeah! YOU GET WHAT YOU PAY,FOR and DURABILITY FOR PARTS TENDS TO COST MORE

GOSFAST posted this great photo to illustrate the differance between rod designs

http://www.scatcrankshafts.com/index.htm

rods designed like the 3 SERIES generally won,t work with stroker cranks while the 2 series usually will

the connecting rods you sellect make a huge differance in the rod to cam lobe clearance, even a small base cam won,t clear some designs, it should be obvious that the connecting rod with the thru bolt has a great deal less cam lobe clearance potentially than the cap screw design next to it., and the cap screw rod probably clears the blocks oil pan rail area easier also.

Im running that crane 119661 cam retarded 4 degrees BTW but detonation has not been a problem, remember that the coolant temp, air temps the engine sees, QUENCH distance, type of head gasket and its construction ,ignition advance,plug heat range,piston to bore clearance, exhaust valve seat width, and oil temp and pollishing your combustion chamber and piston domes, and your AIR/FUEL RATIO , and the effective DYNAMIC compression ratio, have a noticable effect on detonation

and if you do see detonation, theres octane boosters like TOULUENE

http://www.gnttype.org/techarea/misc/octanebooster.html

http://www.team.net/sol/tech/octane_b.html

http://www.elektro.com/~audi/audi/toluene.html

MORE USEFUL INFO

viewtopic.php?f=50&t=1249

ASSUMING your ignition curves correct and your running the correct clearances and KEEPING THE COOLANT TEMP ,in the 190F-200F range and OIL TEMP. in the 190F-215F ranges, if you do a compression check and the PSI reading is above about 200 psi your going to more than likely need an octane booster to avoid detonation problems, if its around 200psi , you can usually get by on 92 octane high test gas, and if its BELOW about 180 psi you can probably use regular octane gas

Last edited by a moderator: