if you measure that insert muffler it quickly becomes obvious that

the internal baffles are highly restrictive too flow and just one look at that internal feed pipe being about 1.6" in diam can,t help but strangle the high rpm exhaust flow .

the side pipes themselves vary in size internally , by brand and model , most muffler inserts, being made for 4" side pipes but measure carefully before you order component parts and be aware that in some cases only the inserts the manufacture of the side pipes sell fit those side pipes correctly!

side pipes look good on a corvette or a cobra and potentially can provide a low restriction exhaust that makes very good power.

obviously noise reduction was a much higher priority in the insert design that performance and most guys that have side pipe exhaust will tell you youll feel a noticeable boost in power if the muffler inserts are removed at the track, but what many guys don,t realize is that once the inserts are removed even better power is available

(generally this requires richer jets and a change in the ignition advance curve) and since there's thousands of potential component combos , and engine displacements gear ratio, compression ratios, cam timing , port sizes etc. only on track testing will generally find the exact best combo.

there's zero doubt that the side pipe exhaust is both rather hot and potentially dangerous if your not careful entering or exiting a corvette after its been running for anything over about 10 minutes it takes for the side pipes to allow the exhaust gases to bring them up to operating temps,

but with some practice and caution you can certainly enter and exit the car very safely without getting burnt, and there,s zero question that if the cars engines properly tuned and if your using low restriction baffles they potentially make very good horse power.

theses at least a dozen different muffler insert designs available,

most are effective at reducing sound levels but most are also very restrictive too exhaust flow rates in the upper rpms ,

making the power seem too hit a wall at some rpm level, obviously dependent on several factors like cam, gearing engine displacement etc,

most cars have an obvious power improvement if you remove the muffler inserts at the track.

if you were under the impression the side pipe muffler inserts were not restricting power try a dyno and careful engine re-tune with them removed, you may be amazed at the difference in power above 4000 rpm.

viewtopic.php?f=80&t=793&p=1150#p1150

viewtopic.php?f=56&t=495

viewtopic.php?f=56&t=1503

viewtopic.php?f=56&t=1166

heres where some welding skill , owning a decent welder and having a willingness to think , research a bit and fabricate makes custom work on an exhaust well worth doing,

all the commercial muffler inserts Ive seen are rather restrictive, Ive seen dyno chart results in the past where the difference was over a 50 hp reduction at peak power between the open headers, exiting into open side pipes on a corvette and the the same corvettes engine run with inserts, inserted.

http://garage.grumpysperformance.com/index.php?threads/is-backpressure-hurting-your-combo.495/

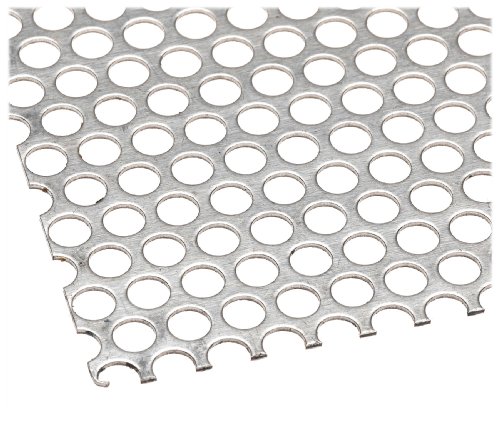

I know when I had my 13.7:1 compression,496 big block , I had hooker side pipe headers installed , we noticed a big difference in MPH with the inserts in place (something like a 3mph reduction) so we simply cut about 12 3.9" diam. circular baffles out of perforated stainless sheet metal

and spaced, 6 of them in each side pipe, spaced out with a threaded rod and 24 nuts and washers spaced about every 6" on a 3 foot long section of 1/2" threaded rod, inserted in the center of each perforated stainless baffle plate,and we inserted them in each side pipe ,this perforated sheet we used had about 1/4" holes and about 50% coverage ,and worked reasonably well,at reducing the noise compared to open headers,and allowed us to make decent power , much better than the hooker inserts did, but the insert we made was not as well designed as i would make now, as back then, I had far less understanding of what we were really trying to accomplish, but still it worked.

IF YOU HAVE A DECENT MIG OR TIG WELDER and access to some metal fabrication equipment I think youll be far ahead if you take the time and effort to use perforated steel sheet and tube or pipe too custom build side pipe insert mufflers, similar to the spiralturbobaffles out of perforated steel sheet and steel tube, as the perforated steel tube and sheet material lends it self quite well to the application while allowing both good flow rates and good sound wave disruption, a custom pattern made from cardboard, for the baffles and the perforated central 1"-1.5" pipe would not be dirt cheap but would be available if you shop carefully and flow better than the spiralturbobaffles

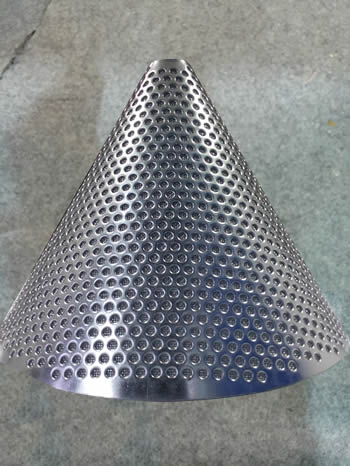

theres also exhaust insert cones whose total open surface area exceeds the diameter , because the geometry of the surface area of a cone allows a greater surface area on the surface than the base but I think the smallest is 3" diam.

that you can fabricate something similar much cheaper,if you weld, these cones are expensive if you buy them, but hardly difficult to fabricate,

it certainly would not be all that difficult to fabricate an exact fit pattern out of poster board then use that to cut perforated sheet steel to make your own, custom, perfect fitting, muffler insert baffle, versions, that easily out flow the standard insert mufflers.

https://www.speedwaymotors.com/Dyna...Bz6emuEjF4N1k5y0bOy7WTF0w3YWiZOoaAiIGEALw_wcB

If your not into fabricating you could make a poster board pattern and have a local sheet metal shop fabricate them for you, obviously not as cost effective but still most likely a bit cheaper

stuff 2-to-4 of the cones equally spaced on a threaded rod with washers and nuts to maintain spacing inside the corvettes side exhaust pipe instead of the restrictive factory inserts , and you'll have very low exhaust flow restriction, good sound wave disruption a WIN/WIN situation.

Even if your 100% correct that the on-line calculators only provide a basic place to start on the header design, and are not going to provide exact data, the basic well dyno proven fact is that almost all the commercial headers were and are designed with fit and ease of fabrication as the primary design parameters and

max performance far down the list.

low cost and ease of manufacture , and designing a single header too fit as many applications as possible to simplify inventory issues, has almost always been the manufacturers goal.

longer primary tube length has frequently proven too provide both more mid rpm torque and more average torque, and its the torque within 2000-rpm-to -3000 -rpm of the peak torque that moves the car during almost all the time in performance use.

longer tubes cost more money and make the header harder to design too fit well, so most manufactures rather design a shorter header design that may fit several similar cars rather than the ideal longer header for a single application.

4 into two, into one collector designs (LIKE BELOW)have also proven to be excellent performers,

but the generally work best if the cam timing and high compression are well matched

one of the rather well established racer tricks has always been to run open collectors too reduce back pressure, as

( headers scavenge best, with zero back pressure)

and in many cases, where clearances allowed, we cut the collectors of commercial headers , and welded on pre made extensions

(LIKE THESE BELOW)and almost always saw a boost in performance

https://www.summitracing.com/parts/FLO-C134218234/

one reason side exhaust on corvettes were and are used is the design allowed decent ground clearance AND long efficient header primary tube header designs.

of course side exhaust might be one reason Ive always prefered engineer boots and levi jeans

https://www.cmrp.com/cone-calculator

https://www.blocklayer.com/cone-patterns.aspx

http://craig-russell.co.uk/demos/cone_calculator/

http://theurbanfarmingguys.com/iFrameTest.htm

https://planetcalc.com/3831/

https://www.blocklayer.com/cone-patternseng.aspx