I recently acquired a low mileage 350 crate motor (mexico) that precious owner attempted to install hotter cam and heads on. Clearly the cam break in did not go so well. He was so disgusted that he pulled it and it sat wrapped up in the corner for several years. After I got my hands on it, I disassembled and cleaned it all up. Plans are to replace all bearings, and install a mild cam in it, and just make a good runner for my work truck.

Question is, most of the wrist pins are very tight. I've used heat gun and penetrating oil, dipped in hot motor oil, and then tried ATF to free up. They become slack after 15-30 seconds in hot oil, but once cooled they are stiff again. Is there a magic bullet to fix this, or am I SOL and spending more money on machine shop? Money is tight, any insight is appreciated.

I've got too ask...are the wrist pins designed to be free floating or are they using stock pistons?

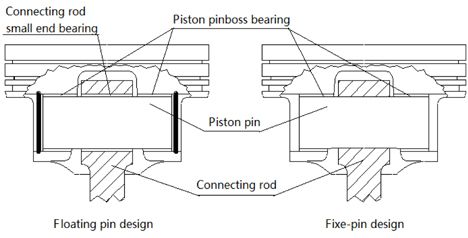

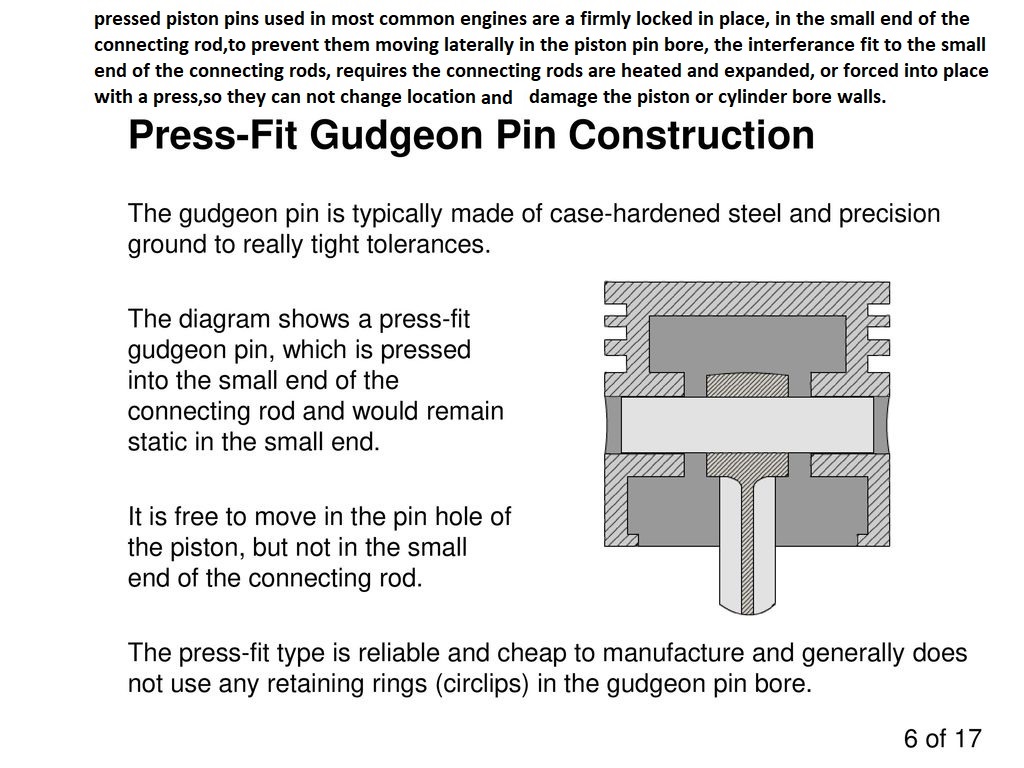

stock pressed wrist pins are locked in the small end of the connecting rod, and only rotate in the piston wrist pin bore.

the first step in solving any potential problem is in determining exactly what your dealing with

and how its designed to work.

most crate motors use pressed in piston pins,

not free floating piston wrist pins

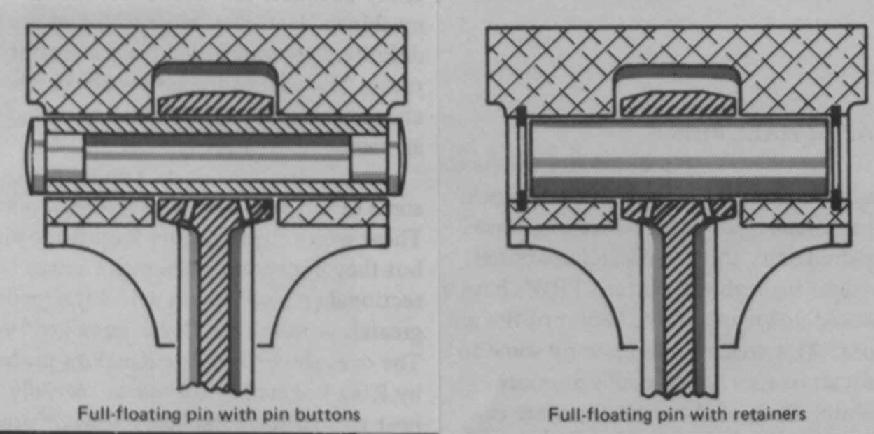

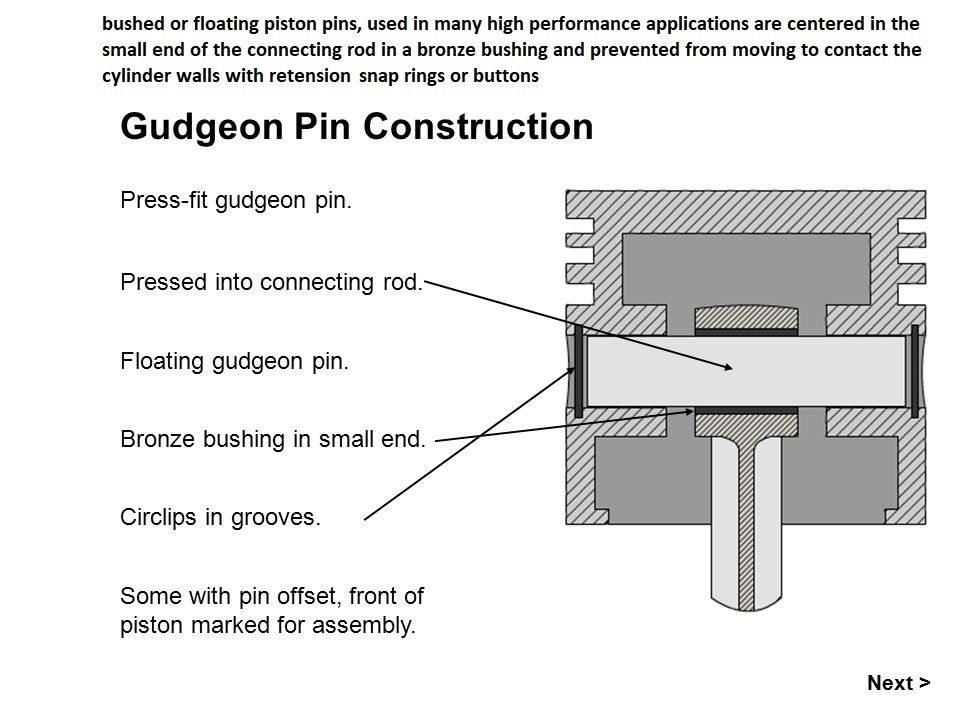

free floating piston wrist pins rotate in the connecting rod small end and in the piston pin bores

pressed wrist pins are designed to be firmly locked in the connecting rod small end and only rotate in the piston pin bore's

most stock engines use pressed wrist pins, it requires pistons designed to use free floating wrist pins to use free float or bushed wrist pins.

if the wrist pins are designed to move in the rods small end the piston will be designed to keep the wrist pin centered in the piston,

pistons without a design to retain the wrist pin use pressed in wrist pins,

that should not be free to move in the connecting rod small end.

read these links, (below) and Id certainly pull a rod and piston,

and determine exactly what type of piston and wrist pin combo your dealing with for sure.

http://garage.grumpysperformance.co...n-wrist-pins-one-really-over-looked-part.978/

http://garage.grumpysperformance.co...g-and-installing-connecting-rods-pistons.247/

http://garage.grumpysperformance.com/index.php?threads/what-con-rods-would-you-buy.942/#post-67580

http://garage.grumpysperformance.co...ing-rod-strength-h-vs-i-beam.1168/#post-41255

http://garage.grumpysperformance.com/index.php?threads/reusing-stock-connecting-rods.702/#post-975

http://garage.grumpysperformance.com/index.php?threads/connecting-rod-weights.3540/#post-9394

http://garage.grumpysperformance.co...market-4340-connecting-rods.13321/#post-72048

Last edited: