I recently had a guy ask me to track down the reason his 1985-1991 TPI corvette would not start,

now on the 1996 you can use a code scanner,

because pre-1996 corvettes are not OBDII code scanner compatible you'll need to use the trouble code flasher to get the trouble codes

all the answers are readily available, theres known testing procedures and listed test results you can expect, and procedures listed in the shop manual for isolating and testing components, you don,t need to be a genius, you just need to be logical and persistent and not afraid to learn new things while getting your hands dirty at times, don,t get overwhelmed , break everything down too easy individual problems and tests, verify and test all the sensors,and test for factors like consistent fuel pressure, known temps,expected voltage or ohms resistance, and vacuum readings and don,t randomly start replacing parts as that gets expensive and its rarely the most efficient way to eliminate problems(unless you get really lucky) with modern computer diagnostic software you,ll have some advantages but think logically, most automotive problems still concern, loose electrical connectors, defective sensors, lack of compression, fuel delivery issues ,fuel pressure, vacuum, temperature or electrical issues.

gas as a liquid fuel ,does not burn well, GAS vapor does ignite easily, the hotter the engine is the more rapidly the liquid gas vaporizes thus making starting the engine more easily, the 9th injector is used to richen the F/A mix, to make starting far easier, later engine versions use a software change that lengthens the injector pulse duration to significantly richen the F/A mix its this longer duration in a cold engine that makes starting easier, so you either require the 9th injector or the more updated software that uses the engine temp software to make starting the cold engine easier

TUNING SKILLS MAY BE VERY USEFUL

viewtopic.php?f=55&t=109&p=44341&hilit=+reading+plugs#p44341

viewtopic.php?f=50&t=383&p=470&hilit=vacuum+gauge#p470

a leak down tester is always a good test tool to have access too

viewtopic.php?f=50&t=41&p=49&hilit=+leak+gauge#p49

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

If your injectors are leaking, injectors obviously should be under the control of the CPU and should not remain fully open to drip fuel constantly.

carefully visually inspect your cars wire harness for corrosion ,loose or broken or shorting connectors or wiring, obviously getting the wrong electrical pulse, a grounded or shorted connector will cause problems. visually inspect each injector pigtail for loose broken or shorted or grounded connectors or wires

first verify your getting a pulse at each injector and you have 38-42 psi at the fuel rail shrader valve.

its as usual a case of isolate and test , if the injectors are stuck open the injectors defective or its in need of a careful commercial professional cleaning, verify if its the injector or the injector control pulse duration

replacement injector pig tails are available at rock auto for less than $5 each

http://www.harborfreight.com/11-piece-noid-light-and-iac-tester-set-97959.html

http://www.helminc.com/helm

now theres a logical and methodical ,way to approach a situation like that and it requires a few tools and a bit of common sense and logic.

id start with asking if you hit the starter does the engine spin over?

if not youll need a multi meter to verify your battery is fully charged.

use of a shop manual and multi meter can be very helpful

assuming its spinning the engine but just not firing up?

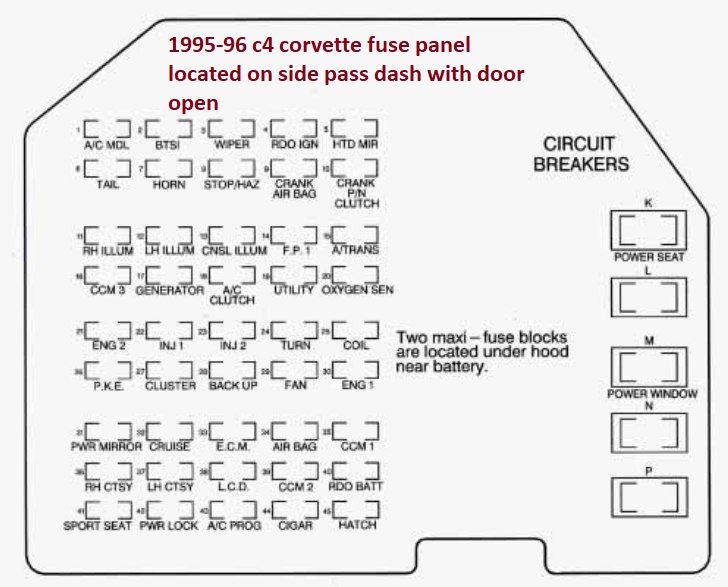

Id suggest you pull trouble codes and check for a blown fuse, in the pass dash door area and under the hood near the battery fuse bank areas.

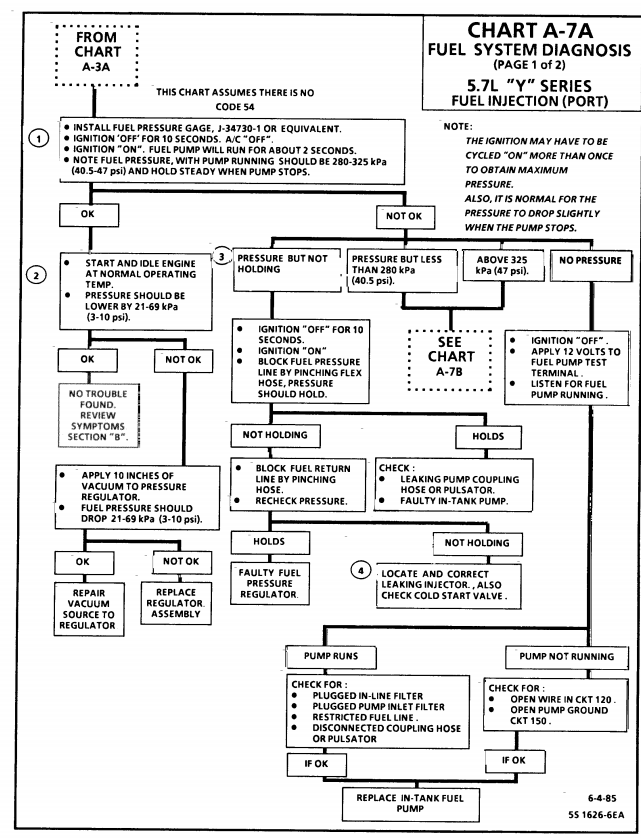

check the fuel rails for fuel pressure!

a vacuum and fuel pressure gauge is useful

http://garage.grumpysperformance.co...le-shooting-flow-chart-info.11536/#post-71845

without testing you simply guessing

never guess, deal in verified FACTS!

guessing is a waste of time

think logically, isolate and test

yes IM aware some guys would rather dig out their eye with a red hot fork than to read links, but if you take the time to actually research the problem and isolate and test you,ll soon find the answers

well the first thing you do is pull trouble codes

and it would help if you purchased a shop manual.

yes a decent infrared temp gun is a helpful diagnostic tool

keep in mind , even if everything running well,

the front two cylinders tend to run a small amount cooler (20 degrees) simply because the increased cooler air flow over the header tubes

the actual exhaust gas and header temp will vary with the combo specs , your looking for consistency not a specific temperature at the exhaust ports

http://garage.grumpysperformance.co...-won-t-start-intermittently.14212/#post-72158

these related links should also help check for fuel nrail fuel pressure, check your getting a pulse on both banks of fuel injector pigtails with a NOID LIGHT TESTER

VERIFY

YOUR GETTING IGNITION SPARK, easily done, pull an ignition wire off the easiest to reach spark plug, insert a phillips screw driver into the spark plug wire and hold the insulated handle so the steel shaft of the screw driver is about 3/16" from ground and have a buddy try to start the car, you should see intermittent spark arcs from the gap between the screw driver and ground, It certainly won,t hurt to pull and inspect the spark plugs, if they don,t look to be in good condition replacing them is almost mandatory, if you see coolant or rust on a spark plug this strongly suggest a blown head gasket

http://garage.grumpysperformance.com/index.php?threads/spark-plug-info.202/

http://garage.grumpysperformance.com/index.php?threads/installing-hard-to-access-plugs.962/

http://garage.grumpysperformance.com/index.php?threads/timing-lights.875/

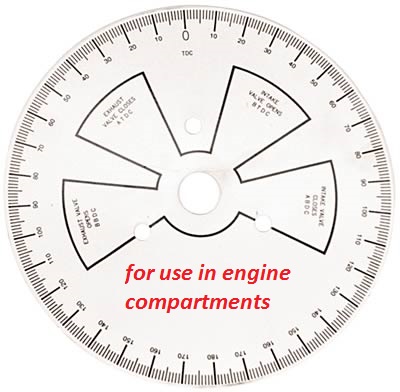

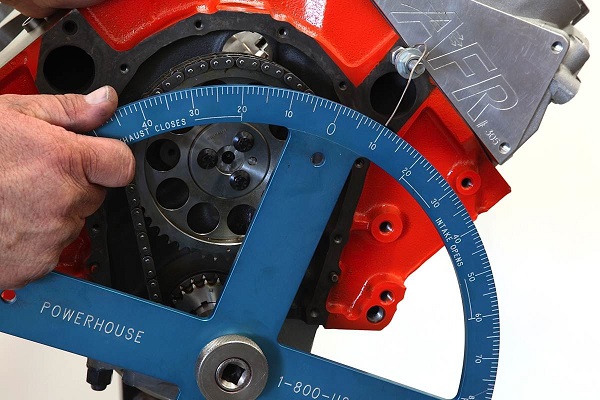

checking your firing order and ignition timing can be critical, so do the required checks,

http://garage.grumpysperformance.com/index.php?threads/finding-top-dead-center.967/

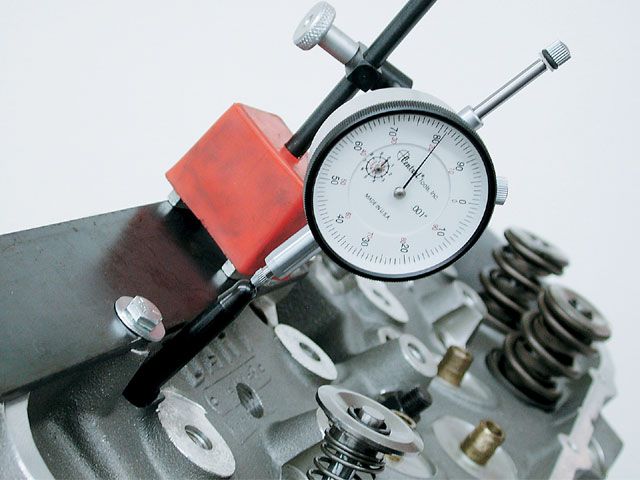

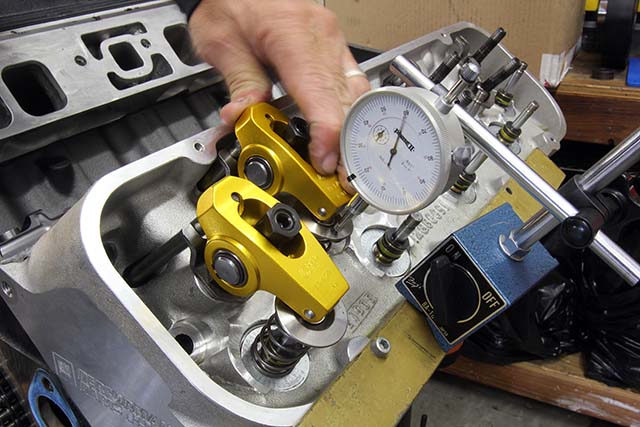

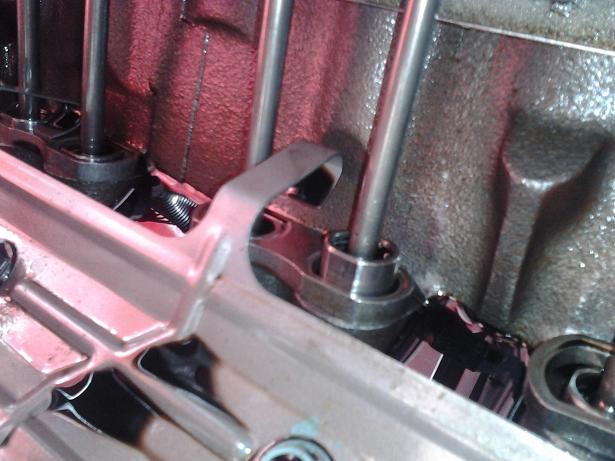

youll also want to verify the valves are properly adjusted,

http://garage.grumpysperformance.com/index.php?threads/correctly-adjusting-valves.196/

https://www.corvettemods.com/C4-C5-Corvette-1985-2004-Fuel-Injectors---Set-of-8---96lbhr---1000cc_p_17958.html?gclid=EAIaIQobChMIq8HDsqO69gIVoQaKAx1uHwGmEAEYASABEgKWQPD_BwE be sure you calculate the correct size injector and be sure you order the correct size injectors you need be sure to...

garage.grumpysperformance.com

http://garage.grumpysperformance.com/index.php?threads/locating-vacume-leaks.882/#post-1390

http://garage.grumpysperformance.co...ystem-trouble-shooting-flow-chart-info.11536/

http://garage.grumpysperformance.com/index.php?threads/fuel-pressure-regulators.635/

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...es-got-me-scratching-my-head.7499/#post-25434

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.com/index.php?threads/setting-up-your-fuel-system.211/

http://garage.grumpysperformance.co...-won-t-start-intermittently.14212/#post-72158

L98/ TPI Engine Start Sequence

When you start an L-98 engine Corvette, a series of events take place that causes the engine to run. Knowing the sequence will help you troubleshoot no start conditions.

Fuel Rail Pressurization:

When you first turn the key to the “on” position, the fuel pump will run for 2 seconds pressurizing the fuel rails. There is a Shraeder valve on the passenger side fuel rail near the rear of the engine and if you measure the pressure there after the pump runs, you should see between 40-42 pounds of pressure. The reading will go to 38-40 pounds nominal once the engine is running.

Initial Crank Action:

If you then rotate the key to the start position (assuming the anti-theft system has not disabled the starter), the engine will rotate.

Once the oil pressure has reached 4 PSI, the oil pressure switch will close allowing the fuel pump to run. (Note that you should have a black oil pressure switch/sender. It is mounted behind the distributor on the driver’s side and if it is not black, it is suspect due to a run of bad units that stayed in the GM parts pipeline for some time).

The distributor will send a string of pulses to the ECM (Engine Control Module) in response to the engine being rotated by the starter. These pulses continue as long as the engine turns (both starting and running) and if they are not present, the engine will not run.

ECM Reaction:

If the ECM sees oil pressure greater than 4 PSI and the reference pulses from the distributor, it will energize the injector drivers which will begin pulsing the injectors on for 4 ms (milliseconds) periods. (In the L98, all injectors on one side of the engine fire at the same time followed by all injectors on the other side firing at the same time. On the LT-1, the injectors are fired individually at the appropriate time).

The ECM will also pull in the fuel pump relay in effect paralleling it electrically with the oil pressure switch. (If the fuel pump relay fails, you can still normally get the car to start and run unless you can’t make at least 4 PSI oil pressure. This is a “limp home mode” feature put in place to allow for a fuel pump relay failure).

The ECM also monitors the TPS (Throttle Position Sensor mounted on the throttle body assembly) and wants to see .54 volts at this time. If it sees appreciably more than 0.54 volts, it will assume the engine is flooded and the driver has pressed the accelerator to the floor to clear the flooded condition and restrict the fuel flow as a result. (.54 volts during start and at idle from the TPS is very important to both starting and run performance.)

Assuming the ignition module is good (meaning there is a spark of sufficient intensity to ignite the fuel), the engine will “catch”.

Engine "Catches":

When the engine catches, the MAF (Mass Air Flow sensor mounted just ahead of the throttle body) sends a signal to the ECM advising that air is flowing and also just how much air is being pulled through to the intake manifold. The ECM takes note of the amount of air being consumed and adjusts the injector pulse width to around 2.2 ms nominally so as to attain a proper air/fuel mixture to insure combustion. (This is how the 1985 through 1989 L-98 works. For information on the 1990 and 1991 L-98 variant, see the Note below).

The engine should show an initial idle speed of around 900-1100 RPM and then slowly diminish to 600-700 RPM unless the air conditioner is on in which case it will run at around 800 RPM.

If this does not happen, the Idle Air Mixture valve (located on the throttle body) may be misadjusted. Alternatively, there may be a leak in the intake manifold or another vacuum leak may be present. Listen for hissing sounds---there should be none.

ECM Mode:

The engine will now be in Open Loop mode meaning that the ECM is controlling the air/fuel mixture by referencing values stored in memory.

Once the Oxygen sensor (mounted on the exhaust pipe) reaches operating temperature of several hundred degrees, the Manifold Air Temperature (MAT) sensor shows an intake air temperature of more than 140 degrees and the Engine Coolant Temperature (ECT) has reached 160 degrees, the computer will switch to closed loop mode meaning the Oxygen sensor’s output is examined along with the MAT and ECT outputs and the ECM adjusts the injector pulse widths (more “on time” or less “on time”) to constantly strive for a 14.7:1 air/fuel mixture which is the best mixture to hold down pollution.

Note that prolonged idling can force the computer back into open loop mode.

Note: In 1990, the MAF was eliminated from the engine in favor of a speed/density system. This system uses a sensor called the MAP sensor which measures the Manifold Absolute Pressure (hence the name MAP) and compares it with the atmospheric pressure outside the intake manifold. This information, coupled with the Manifold Air Temperature, Engine Coolant Temperature and Engine RPM is used by the ECM to determine the amount of air entering the cylinders. It is a different way of reaching the desired 14.7:1 air-fuel mixture ratio but functionally is like the MAF system in that the ECM uses the feedback to control the "on time" for the injectors.

Corvette used this approach in the 1990 and 1991 L-98 engines and in the 1992 and 1993 LT-1 engines. With the 1994 model C4, they went back to the MAF system. Note that MAF based systems are far more accurate since they measure air flow directly whereas the MAP system infers air flow indirectly. A multitude of things can throw the calculation off and Corvette returned to the MAF system beginning with the 1994 C4 (with a MAP backup). From a troubleshooting standpoint, the MAP operation comes into the sequence the same place that the MAF does.

Summary:

If you have a no start condition or if the L-98 starts and then dies, check the above items in sequence to see if all the events are occurring as required.

A Scan Tool makes this job much easier and is a highly recommended troubleshooting aid for these sorts of problems.

youll find a hour or so reading thru the links and sub links, on this site in the threads, will provide a great wealth of related info and incite into related factors, or the function or testing of sensors, that you may not currently be thinking about, or things that you might not think that are related to your issue that PROBABLY ARE

without testing your simply guessing READ THE LINKS AND SUB LINKS AND THINK LOGICALLY... AND ASK

QUESTIONS

http://garage.grumpysperformance.com/index.php?threads/c4-c5-corvette-trouble-codes.2697/

http://garage.grumpysperformance.co...start-right-back-up-and-run.10739/#post-46893

http://garage.grumpysperformance.com/index.php?threads/tpi-fuel-pressure-issue.10385/#post-42943

http://garage.grumpysperformance.co...ouble-shooting-rebuilding-hei-ignitions.2798/

http://garage.grumpysperformance.co...years-now-i-want-to-sell-it.13790/#post-70731

http://garage.grumpysperformance.co...ard-starting-tpi-crossfire-or-lt1-vette.1401/

http://garage.grumpysperformance.co...lay-switch-locations-and-info.728/#post-54562

http://garage.grumpysperformance.com/index.php?threads/adjusting-your-tps-and-iac.168/

http://garage.grumpysperformance.co...-system-trouble-shooting-flow-chart-info.596/

http://garage.grumpysperformance.co...-system-vats-making-you-crazy.520/#post-45062

http://garage.grumpysperformance.co...s-cause-a-bad-idle-in-drive.14203/#post-72114

http://garage.grumpysperformance.co...questions-can-be-found-here.12892/#post-67808

1989 sitting for 15 years - Crank but no start 1989 C4 ... 142K miles. Sat indoors for 15 years. Cranks but will not start. Drained old gas, replaced fuel pump, sending unit, fuel filter. Fuel pressure is a solid 45psi with the pump is running, drops to 40psi when pump is not running. There...

garage.grumpysperformance.com