Would gaining .040" lift be worth a $500-$600 investment? Got a 350 Chevy, with aprox 300HP. How much HP would I gain? I read in Chevy High Pref magazine years ago, that if you invest more than $10 to gain 1 HP, the costs will outgain the rewards.

without facts you can,t reasonably make anything like a valid prediction,

generally a .040 lift increase at the valve only ,

will not be overly significant in aiding power

to make an accurate guess the person ,

doing so needs a valid reference point to start from based on

what the average similar engine build has done using similar components in hundreds of similar engine builds

post a great deal more info about your current engine parts list, compression, displacement, cylinder head flow rates, cam duration and lift, cam type, ie roller or flat tappet,hydraulic or solid lifter,exhaust system info, fuel octane, , heads etc.

Id need to know more about any combo including both the engine and drive train trans and gearing and car weight and I can give you some decent advice based on both experience and a soft ware prediction

other wise its just random guess work

yeah I can make an educated prediction, but it needs to be firmly based on facts

yes theres soft ware thats been developed specifically to do this type of prediction,

but it needs a valid set of reference info

yes as usual read the links and think logically,

doing some detailed research, before you start writing checks,

is almost always going to save you from wasting cash and your time.

you might be amazed at how that helps your results later.

learn to ask detailed questions before the check book gets used.

http://garage.grumpysperformance.com/index.php?threads/virtual-dyno-software.2301/#post-9239

http://garage.grumpysperformance.com/index.php?threads/camquest.2926/#post-7652

http://garage.grumpysperformance.co...good-street-combo-your-after.5078/#post-14433

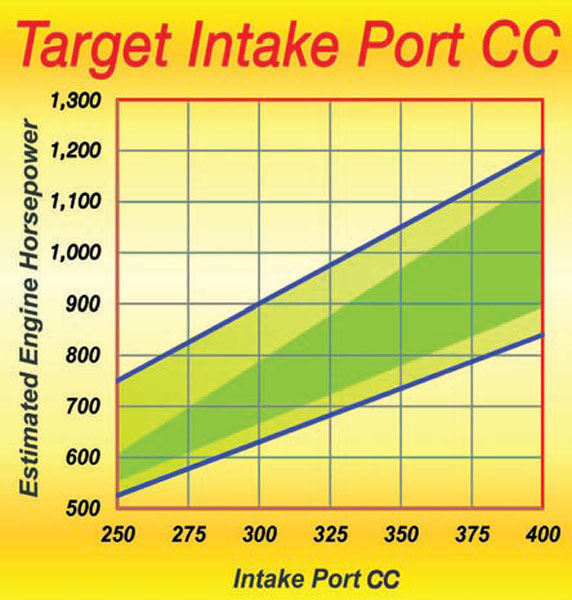

http://garage.grumpysperformance.com/index.php?threads/port-speeds-and-area.333/#post-37693

http://garage.grumpysperformance.com/index.php?threads/how-to-read-a-cam-spec-card.1477/#post-13044

http://garage.grumpysperformance.co...t-get-anticipated-hp-results.6853/#post-22236

Last edited: