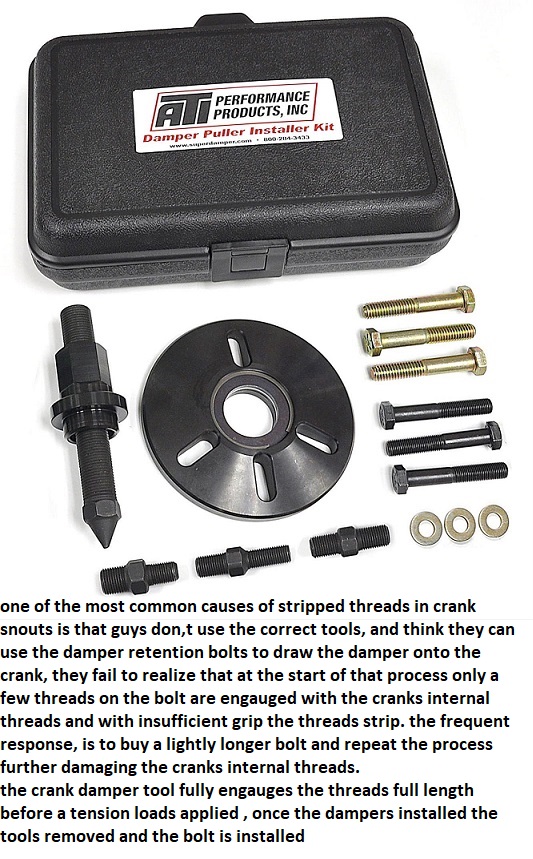

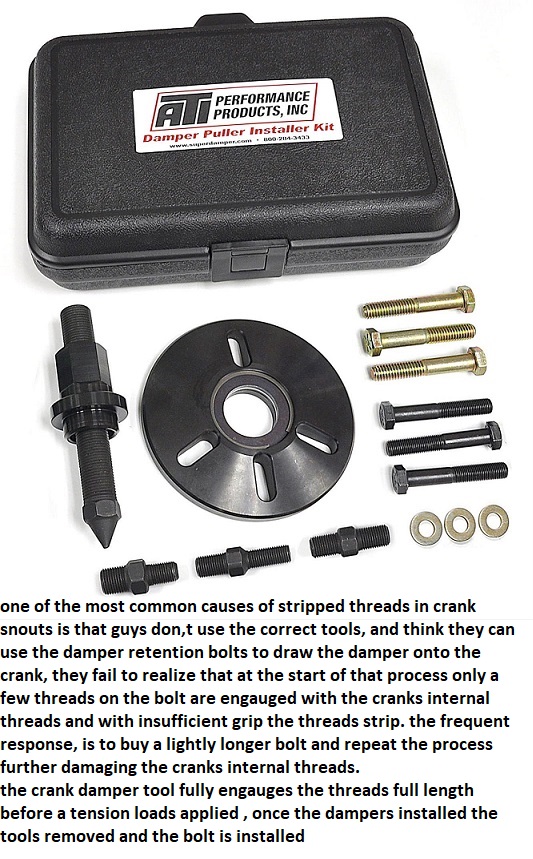

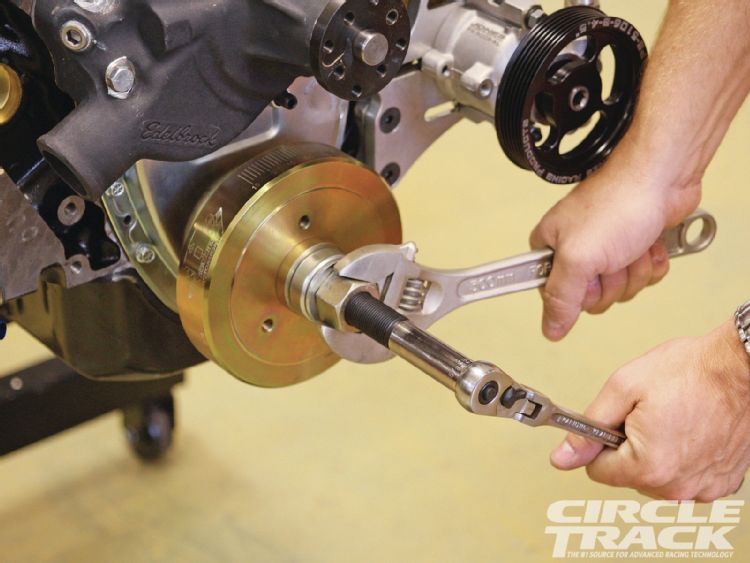

now its been my experience that most stripped crank threads are the results of guys trying to use the damper retaining bolt to draw on the damper rather than use the tool that's designed for the job.only a small percentage of the threads are engaged during the first few fractions of an inch of the process and they will easily pull out or strip, the correct tool will be engaged with about 90% of the threads , before the tension loads are applied,so it won,t have that tendency to strip threads.

read these two threads (below)first, they contain a good deal of info you need to know and understand! and it may prevent you needing to repair your crank or have striped threads

http://www.jegs.com/p/ARP/ARP-Harmonic- ... 6/10002/-1

viewtopic.php?f=53&t=1480

http://www.crouchsales.com/hex-bolts-grade-8-fine.aspx

http://www.atiracing.com/products/dampe ... ctions.htm

viewtopic.php?f=53&t=83

http://www.go-fast.org/z28/damper.html

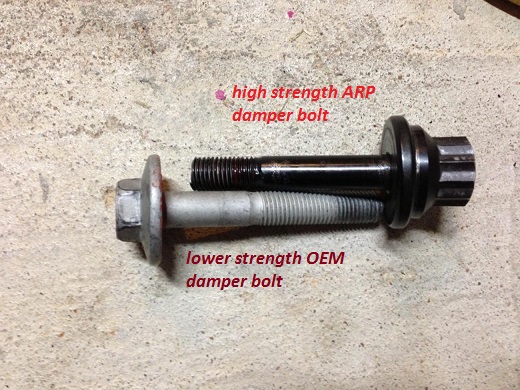

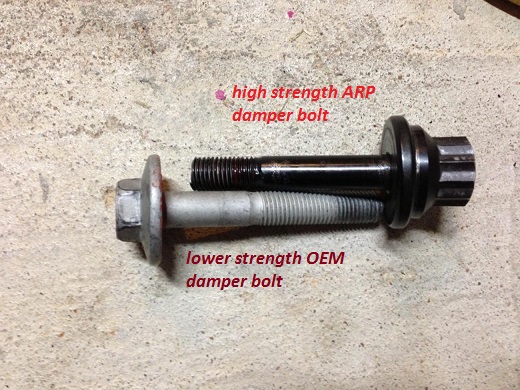

btw if youve ever tried to draw on a damper with a crank bolt from a local hard ware store this is frequently the result, that or stripped crank threads, ID strongly suggest use of the correct Damper tool, and use of ARP crank bolts once its properly installed

next time BUY AND USE AN ARP BRAND BOLT

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

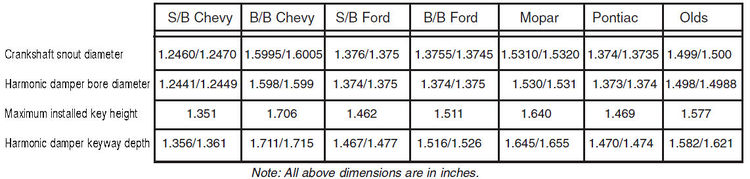

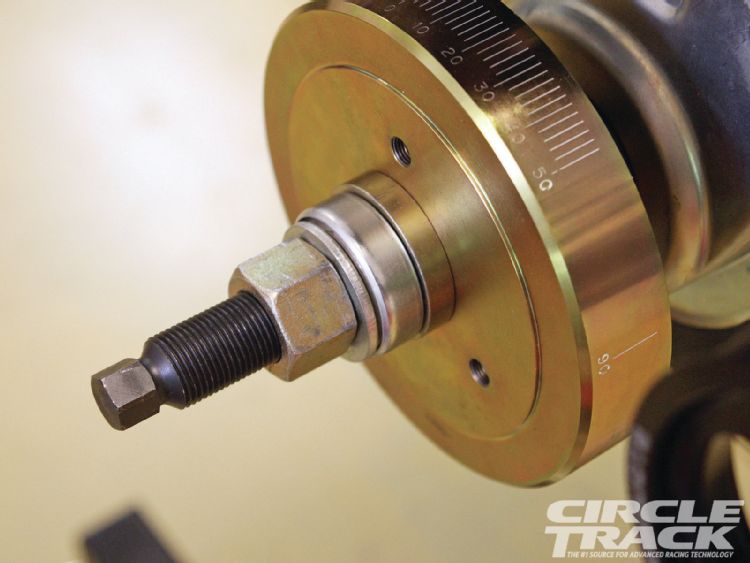

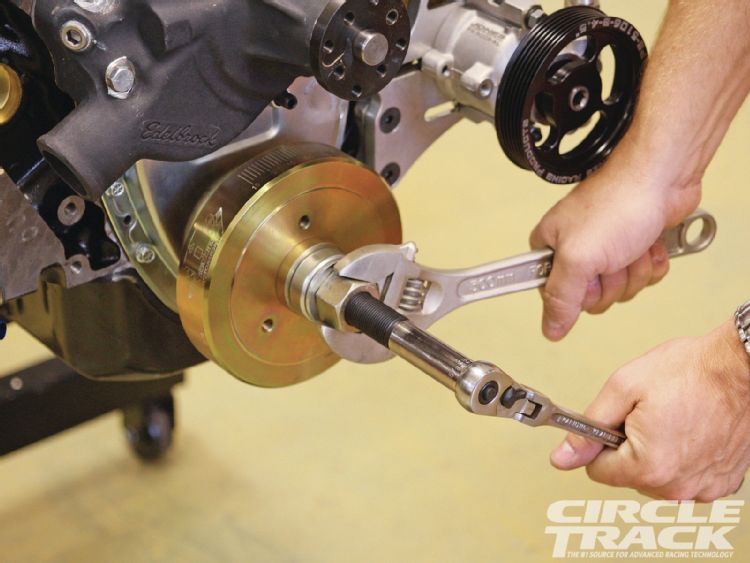

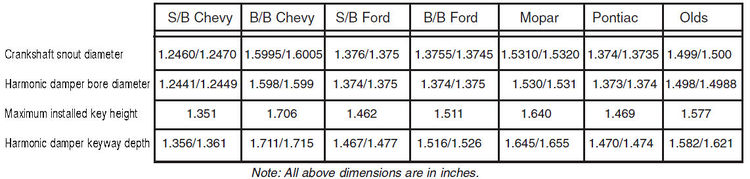

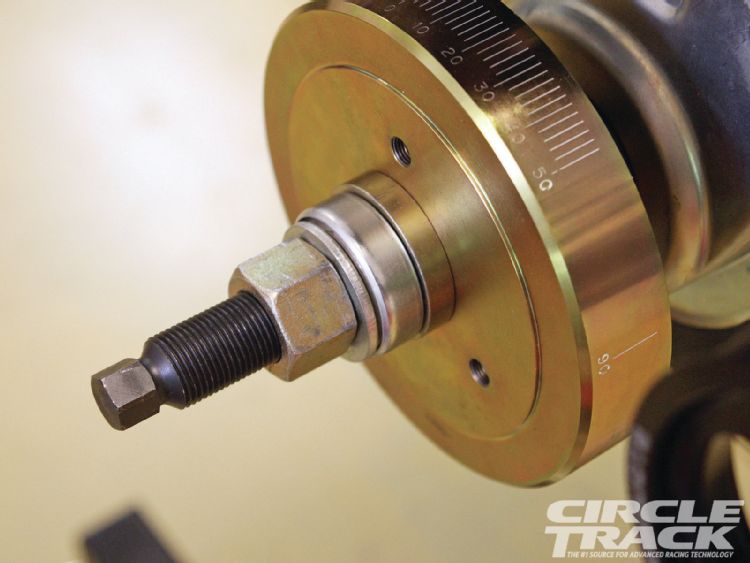

Measure the crank-snout diameter with a micrometer (above left). Ours measured 1.600 inch, which is right on spec. Then use a dial-bore gauge to determine the inside diameter of the Fluidampr damper (below). Ours came in 1.599-inch, resulting in a .001-inch interference fit. This is the right amount of clearance to provide a good snug fit on the crankshaft, but still be able to install and remove without difficulty. Another method of measuring the damper hub ID of your is with a snap gauge (above right). After setting the gauge, the micrometer is used to to determine the final measurement. In this case, the same measurement as the dial bore gage was reached.

http://www.enginebuildermag.com/Article ... stons.aspx

http://www.arp-bolts.com/

http://www.summitracing.com/parts/ARP-134-2501/

http://www.summitracing.com/parts/ARP-234-2503/

viewtopic.php?f=53&t=1798&hilit=damper

viewtopic.php?f=53&t=1480&hilit=+damper

viewtopic.php?f=53&t=1798

if your current crank bolt is an ARP bolt, heres the dimensions,

keep in mind a bolt threaded in steel should have 1.5 times its diam. MINIMUM in the threads before the bolt starts to draw or tighten or clamp and TWICE its diam. in the threads is better as a minimum to prevent stripped threads, and remember the bolt should never be allowed to bottom out in the crank snout threads and tighten against the bottom of the drilled hole either

Summit Racing Part Number ARP-134-2501

Thread Size 7/16-20 RH in.

Underhead Length (in) 2.470 in.

Head Style 12-point

Washer Included Yes

Fastener Yield Strength (psi) 200,000 psi

Fastener Material Chromemoly

Fastener Finish Black oxide

Quantity Sold individually.

Notes Features 5/8 in. socket size.

One tough bolt.

As the crankshaft flexes, the damper absorbs incredible amounts of energy. These damper bolt kits from ARP will ensure that your balancer is locked into position. They feature a 1/4 in. thick wide-area washer and an extra tall 12-point head that accepts a deep socket to eliminate the fear of stripping the head.

http://www.summitracing.com/parts/ARP-134-2501/

now you can probably re-tap the current threads and use a longer bolt and get by for now, but drilling it with the correct larger drill diam. and re-threading for the big block Chevy bolt is the more common route taken once you strip crank threads

viewtopic.php?f=53&t=1480&p=6221&hilit=stripped+crank#p6221

viewtopic.php?f=53&t=1798&p=5680&hilit=stripped+crank#p5680

there is supposed to be about a .0001 -.0002 INTERFERENCE fit! so the damper has far less tendency to spin on the crank snout or work the woodriff key loose, you can generally polish the crank snout, and internal damper hole with a flap wheel and 400 grit sand paper enough to get a smoother surface, then, place the damper in boiling water to heat and expand it and oil its mating surface, use the correct damper installation tool, pick the damper up with oven mitts so you don,t get burned, use the tool to install it

http://www.summitracing.com/parts/otc-6505

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

https://www.nookandtranny.com/Info_LT1.html

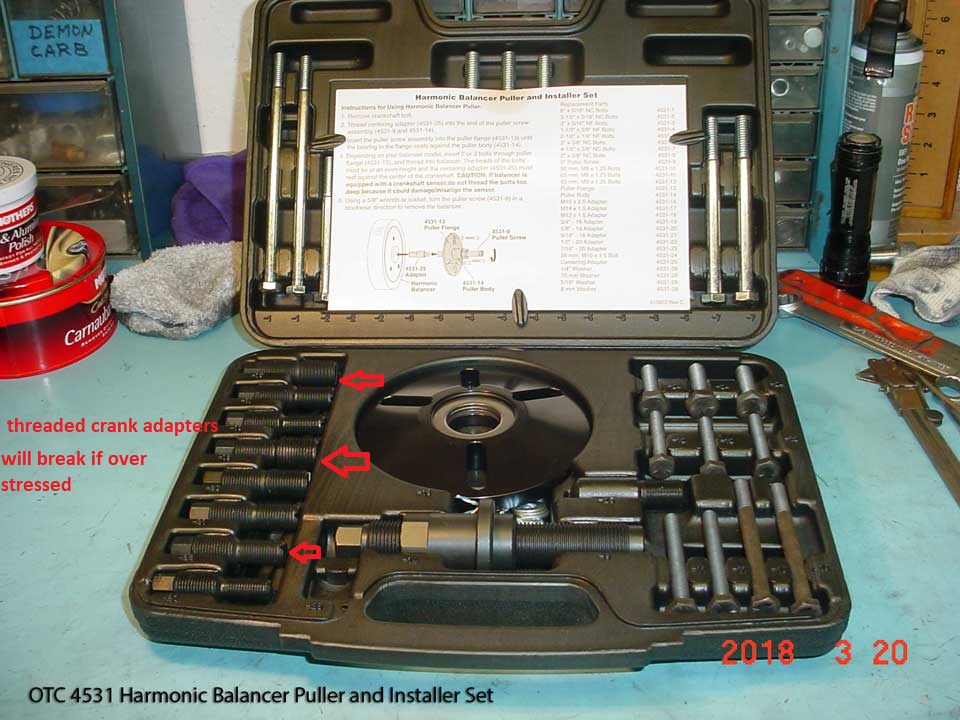

these tools work well, fit most engines and if you do break off a thread adapter you can order a replacement without needing to pay for the whole new tool, and keep in mind the threads strip or adapters break if the dampers OVER TIGHTENED,ALL TOOLS WILL BREAK IF OVER STRESSED, this CAN generally be avoided with simply taking a few accurate measurements and use of some marvel mystery oil on the damper, crank and the installing tool threads

Yes I busted one thread adapter years back , but it was a P.I.T.A. waiting on a replacement and I learned not to over tighten the tool, and watch carefully on the measurements and have not had that happen for 30 plus years keeping the tool and damper and crank snout well lubed makes it slide on easier

measuring and checking the interference fits correct helps

read thru these threads, for info on seating a damper and re-threading a stripped crank

http://www.summitracing.com/parts/ATI-9 ... mage=large

http://www.fluidampr.com/DOWNLOADS/STRE ... NSTALL.pdf

drill and tap sets

http://www.amazon.com/Tap-Drill-Set-met ... roduct_top

sbc engines are normally threaded for 1/2" SAE fine threads and BBC for 7/16" SAE FINE threads

ITS not uncommon to drill and tap the 1/2" sbc chevy cranks when they get stripped threads to the larger big block chevy damper bolt to repair those stripped threads to the larger 7/16" thread size or the larger 7/16" bbc cranks for the 9/16 SAE or 5/8" SAE fine threads

now re-threading the sbc crank for the larger BBC thread size presents no huge problems, but the standard balancer installation tool wont fit the 5/8" threads

a grade 8 bolt about 6" long and a large stack of about 2" of 9/16" or 5/8" FENDER WASHERS and a NUT threaded for the 9/16" or 5/8" THREAD can FREQUENTLY be used as an emergency tool if you grease the washers, nut and threads with moly assembly lube

for those guys that don,t know thats a

9/16"-18 or 5/8" -18 tap size youll be using to re- thread the crank[/b]

tap----------drill size

9/16-18 33/64

5/8-18 37/64

http://buy1.snapon.com/catalog/item.asp ... up_ID=1166

http://www.victornet.com/cgi-bin/victor ... Drill.html

http://www.tavia.com/cat12.html#1

BROKEN BOLT REMOVAL

viewtopic.php?f=50&t=729&p=1026#p1026

read these two threads (below)first, they contain a good deal of info you need to know and understand! and it may prevent you needing to repair your crank or have striped threads

http://www.jegs.com/p/ARP/ARP-Harmonic- ... 6/10002/-1

viewtopic.php?f=53&t=1480

http://www.crouchsales.com/hex-bolts-grade-8-fine.aspx

http://www.atiracing.com/products/dampe ... ctions.htm

viewtopic.php?f=53&t=83

http://www.go-fast.org/z28/damper.html

btw if youve ever tried to draw on a damper with a crank bolt from a local hard ware store this is frequently the result, that or stripped crank threads, ID strongly suggest use of the correct Damper tool, and use of ARP crank bolts once its properly installed

next time BUY AND USE AN ARP BRAND BOLT

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

Measure the crank-snout diameter with a micrometer (above left). Ours measured 1.600 inch, which is right on spec. Then use a dial-bore gauge to determine the inside diameter of the Fluidampr damper (below). Ours came in 1.599-inch, resulting in a .001-inch interference fit. This is the right amount of clearance to provide a good snug fit on the crankshaft, but still be able to install and remove without difficulty. Another method of measuring the damper hub ID of your is with a snap gauge (above right). After setting the gauge, the micrometer is used to to determine the final measurement. In this case, the same measurement as the dial bore gage was reached.

http://www.enginebuildermag.com/Article ... stons.aspx

http://www.arp-bolts.com/

http://www.summitracing.com/parts/ARP-134-2501/

http://www.summitracing.com/parts/ARP-234-2503/

viewtopic.php?f=53&t=1798&hilit=damper

viewtopic.php?f=53&t=1480&hilit=+damper

viewtopic.php?f=53&t=1798

if your current crank bolt is an ARP bolt, heres the dimensions,

keep in mind a bolt threaded in steel should have 1.5 times its diam. MINIMUM in the threads before the bolt starts to draw or tighten or clamp and TWICE its diam. in the threads is better as a minimum to prevent stripped threads, and remember the bolt should never be allowed to bottom out in the crank snout threads and tighten against the bottom of the drilled hole either

Summit Racing Part Number ARP-134-2501

Thread Size 7/16-20 RH in.

Underhead Length (in) 2.470 in.

Head Style 12-point

Washer Included Yes

Fastener Yield Strength (psi) 200,000 psi

Fastener Material Chromemoly

Fastener Finish Black oxide

Quantity Sold individually.

Notes Features 5/8 in. socket size.

One tough bolt.

As the crankshaft flexes, the damper absorbs incredible amounts of energy. These damper bolt kits from ARP will ensure that your balancer is locked into position. They feature a 1/4 in. thick wide-area washer and an extra tall 12-point head that accepts a deep socket to eliminate the fear of stripping the head.

http://www.summitracing.com/parts/ARP-134-2501/

now you can probably re-tap the current threads and use a longer bolt and get by for now, but drilling it with the correct larger drill diam. and re-threading for the big block Chevy bolt is the more common route taken once you strip crank threads

viewtopic.php?f=53&t=1480&p=6221&hilit=stripped+crank#p6221

viewtopic.php?f=53&t=1798&p=5680&hilit=stripped+crank#p5680

there is supposed to be about a .0001 -.0002 INTERFERENCE fit! so the damper has far less tendency to spin on the crank snout or work the woodriff key loose, you can generally polish the crank snout, and internal damper hole with a flap wheel and 400 grit sand paper enough to get a smoother surface, then, place the damper in boiling water to heat and expand it and oil its mating surface, use the correct damper installation tool, pick the damper up with oven mitts so you don,t get burned, use the tool to install it

http://www.summitracing.com/parts/otc-6505

I,ve generally found that if you've stripped the SBC crank snout threads the best answer is to drill and re-thread to the standard and larger BBC crank snout bolt threads size

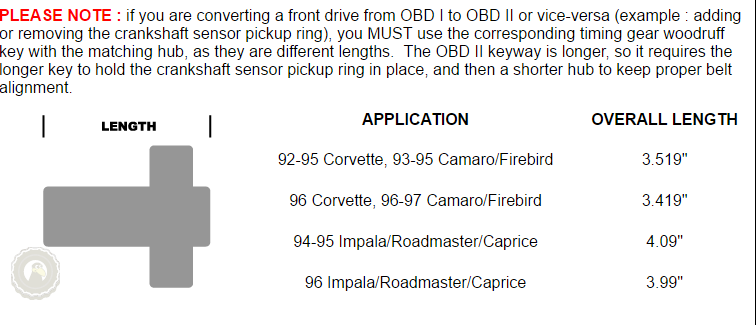

https://www.nookandtranny.com/Info_LT1.html

these tools work well, fit most engines and if you do break off a thread adapter you can order a replacement without needing to pay for the whole new tool, and keep in mind the threads strip or adapters break if the dampers OVER TIGHTENED,ALL TOOLS WILL BREAK IF OVER STRESSED, this CAN generally be avoided with simply taking a few accurate measurements and use of some marvel mystery oil on the damper, crank and the installing tool threads

Yes I busted one thread adapter years back , but it was a P.I.T.A. waiting on a replacement and I learned not to over tighten the tool, and watch carefully on the measurements and have not had that happen for 30 plus years keeping the tool and damper and crank snout well lubed makes it slide on easier

measuring and checking the interference fits correct helps

read thru these threads, for info on seating a damper and re-threading a stripped crank

http://www.summitracing.com/parts/ATI-9 ... mage=large

http://www.fluidampr.com/DOWNLOADS/STRE ... NSTALL.pdf

drill and tap sets

http://www.amazon.com/Tap-Drill-Set-met ... roduct_top

sbc engines are normally threaded for 1/2" SAE fine threads and BBC for 7/16" SAE FINE threads

ITS not uncommon to drill and tap the 1/2" sbc chevy cranks when they get stripped threads to the larger big block chevy damper bolt to repair those stripped threads to the larger 7/16" thread size or the larger 7/16" bbc cranks for the 9/16 SAE or 5/8" SAE fine threads

now re-threading the sbc crank for the larger BBC thread size presents no huge problems, but the standard balancer installation tool wont fit the 5/8" threads

a grade 8 bolt about 6" long and a large stack of about 2" of 9/16" or 5/8" FENDER WASHERS and a NUT threaded for the 9/16" or 5/8" THREAD can FREQUENTLY be used as an emergency tool if you grease the washers, nut and threads with moly assembly lube

for those guys that don,t know thats a

9/16"-18 or 5/8" -18 tap size youll be using to re- thread the crank[/b]

tap----------drill size

9/16-18 33/64

5/8-18 37/64

http://buy1.snapon.com/catalog/item.asp ... up_ID=1166

http://www.victornet.com/cgi-bin/victor ... Drill.html

http://www.tavia.com/cat12.html#1

BROKEN BOLT REMOVAL

viewtopic.php?f=50&t=729&p=1026#p1026

Last edited by a moderator: