http://www.superchevy.com/how-to/46140-chevrolet-transmission-swap-guide/

Chevrolet Transmission Swap Guide - Swap Into Overdrive

A Transmission Swapping Guide for Early Chevrolets

Mike Petralia Sep 1, 1999

2/11

2/11

Overdrive is king of cruise, and GM has done its part to engineer strong, reliable overdrive automatic and manual transmissions for all its new cars. This is the venerable TH700-R4/4L60 manufactured by JET Performance specifically for swapping into early Chevy iron.

3/11

3/11

This is the aftermarket T56 six-speed manual trans available from National Drivetrain. The unit is built by Borg-Warner to handle up to 450 lb-ft of torque and works with a mechanical speedo drive. It is a direct replacement for the weak T5 trans in third-gen Camaros and can be swapped into earlier year Camaros with a bit of fabrication.

Top Searches

Chevrolet Transmission Swap Guide - Swap Into Overdrive

A Transmission Swapping Guide for Early Chevrolets

Mike Petralia Sep 1, 1999

2/11

2/11Overdrive is king of cruise, and GM has done its part to engineer strong, reliable overdrive automatic and manual transmissions for all its new cars. This is the venerable TH700-R4/4L60 manufactured by JET Performance specifically for swapping into early Chevy iron.

3/11

3/11This is the aftermarket T56 six-speed manual trans available from National Drivetrain. The unit is built by Borg-Warner to handle up to 450 lb-ft of torque and works with a mechanical speedo drive. It is a direct replacement for the weak T5 trans in third-gen Camaros and can be swapped into earlier year Camaros with a bit of fabrication.

Top Searches

4/11

4/11

5/11

5/11

This is TCI’s Converter Lockup Control Wiring kit (PN 376600), which allows installation of an overdrive automatic trans with a lockup converter in any non-computer-controlled car.

6/11

6/11

The JET Performance Products Transconversion kit enables the installation of an electronically controlled 4L80-E automatic overdrive trans into any carbureted or fuel-injected car. Its stand-alone computer is programmed to control all trans functions and features a diagnostic port for connection to scanning equipment.

7/11

7/11

Swapping a TH200-4R trans into an early Camaro chassis is simple if you use an original TH400 trans crossmember like this one from Classic Industries. The TH400 and TH200-4R share equal dimensions, and only a TH350 or Powerglide slip-yoke is needed to finish the mechanical portion of this swap.

8/11

8/11

Installing this TH200-4R into a lowered ’67 Camaro required the fabrication of a 3/8-inch-thick aluminum spacer to raise the rear of the transmission and keep driveline angles in sync. In some swaps, it may be necessary to lower the rear of the trans, especially after moving the crossmember back to accommodate a longer trans.

9/11

9/11

This is the Centerforce clutch, flywheel, and pressure plate assembly needed to install a T56 transmission behind an early, two-piece rear-main-seal block. The hydraulic clutch master cylinder assembly for the T56 (PN 12559912) can be purchased complete and pre-bled, ready to install from any Chevrolet dealer.

10/11

10/11

This custom bracket is made from aluminum flat stock and features the proper 22-degree angle for the T56’s hydraulic master cylinder. This bracket, along with the corresponding clutch pedal tab, which gets welded to the factory pedal, must be used to install a T56 hydraulic pull-off-style clutch. They are both available from Westcoast Connections, which can be reached at 707/546-9714.

11/11

11/11

If you’ve bought a used T56 from the scrap yard, the cable-driven speedo in your Camaro won’t work. JTR offers modified extension housings (bottom) for the T56 that allow hookup of the cable and gears for proper speedo operation.

12/11

12/11

While swapping in any of the automatic overdrive transmissions probably won’t cause an exhaust clearance problem, swapping a big T56 into a slammed Camaro may give you nothing but the “scrapes.” It may be necessary to have custom headers fabricated and to install a ministarter to clear the bellhousing.

This is one of those stories that you’ll want to add to your ever-expanding files of Bow Tie knowledge. This trans swapping guide is for early Chevrolet iron and concentrates particularly on first- and second-generation Camaros. It may be the most complete resource guide the crack Chevy High Performance editorial staff has ever created. We have gone to great lengths to supply you with as much swapping information as could be dug up. This guide can tell you what’s involved with—and needed for—swapping any trans into your Bow Tie.

Easy Swaps

By far the most popular conversion is swapping out an original two-speed Powerglide (PG) for a three-speed TH350. The TH350 is a bolt-in replacement for a PG, making this swap a relatively straightforward one that requires no crossmember or driveshaft modifications. The TH350’s steeper First-gear ratio will give you improved acceleration over the two-speed ’Glide. The stock console shifter that controlled the PG will work with the TH350 as well, but you may want to replace the stock indicator bezel with one from a TH350- or TH400-equipped car to keep track of what gear you’re in.

The next easy swap involves replacing either a PG or TH350 with the bigger, stronger, and heavier TH400. This swap is pretty straightforward in any early Chevy, considering that TH400s were optional in most of them. When changing from a PG/TH350 to a TH400, the stock trans crossmember will need to be moved back several inches to align with the TH400 trans mount. If your vehicle ever came equipped stock with a TH400 trans, then you could pick up a crossmember from the scrap yard or a source like Classic Industries, which would allow the TH400 to bolt right into your stock frame. The original TH350 and PG driveshaft won’t need to be shortened because it’s already the correct length, but you must replace its slip-yoke with a 32-spline unit from GM (PN 14075214).

The TH400’s torque converter features a different diameter bolt circle than the TH350/PG converters, but most GM flexplates are already drilled with the necessary dual pattern. If your flexplate has only one bolt circle, you’ll need a dual-pattern replacement, readily available for all Chevy V-8s from sources such as ATI, TCI, and Pioneer. The fittings for the trans cooler lines are in the same location on all three of these automatics, so the plumbing won’t need to be modified. And the same shifter can be used to control either a TH350 or TH400.

Overdrive Automatic Swaps

Starting in the early ’80s, GM began installing four-speed automatic overdrive transmissions to improve gas mileage. Another benefit of these overdrive transmissions was that they featured a much deeper First-gear ratio, giving improved acceleration off the line. Today, the three-speed automatic transmission is extinct and all new GM cars and trucks come with overdrive four-speed automatics, making them easy to find and relatively affordable.

4l60/TH700-R4 Swap

By far the most common overdrive swap has been replacing a three-speed automatic trans with the popular 4L60/TH700-R4 unit. Just so there’s no confusion about which transmission we’re referring to, the 4L60 was the first upgrade made to the venerable TH700-R4. The 4L60 preceded the electronically controlled 4L60-E, which currently comes stock in most of GM’s V-8–powered cars and ½-ton pickups. The nonelectronic 4L60 and TH700-R4 are essentially the same transmissions as far as swapping is concerned, so we’re going to lump them both into the same category. This swap requires minimal fabrication skills and very little in the way of custom modifications.

The TH700 is equipped with a removable tailshaft housing that has varied in length for different vehicles over different years. The tailshaft housing to look for if you’re replacing an original TH400 trans came stock on mid-’80s police cars (Caprice) and the early Impala SS. This tailshaft housing puts the mounting pad almost in line with the original TH400 pad and usually requires only slight elongation of the mounting holes to fit. If you’re replacing a TH350 trans, you can relocate the factory crossmember mounting holes rearward approximately 1½ inches or swap in an original TH400 crossmember.

For either swap, the driveshaft will have to be shortened by as much as 3¾ inches. We recommend mocking up your installation with the TH700-R4 trans in place and then taking measurements to determine how long your new driveshaft will need to be before having it cut. A TH350/PG slip-yoke will work with the TH700-R4 trans, but a TH400’s will not. The TH700 uses a unique torque converter that will bolt right up to a TH350’s flexplate.

TH200-4R Swap

The TH200-4R has been available almost as long as the TH700-R4 but is unanimously overlooked as a performance transmission option. Truth is, the TH200-4R is just as capable and actually easier to swap in than a TH700-R4. It is ideal if you’re replacing a TH350 or Powerglide trans because a TH200-4R will practically install itself into a TH350/Powerglide–equipped car. You may run into transmission oil-pan interference problems when bolting the TH200-4R into early Camaros with the stock TH400 crossmember. The easiest cure is to fabricate a steel or aluminum spacer to raise the back of the trans and slip the spacer in between the mount and the transmission to give it the necessary clearance (see photo). Also, the TH200 uses a torque converter with the smaller TH350 bolt circle. You may have to switch to a dual-pattern flexplate if your car came equipped with the TH400 trans.

Lockup Control

GM had a good idea when it installed lockup torque converters in the overdrive automatics. The purpose of the lockup is to couple the engine directly to the transmission’s output shaft in Fourth gear for the best fuel economy. One design dilemma that comes with the lockup converter is that the transmission only sees full oil pressure when the converter is locked. This can lead to transmissions running hot and living a short life behind a powerful engine. But most aftermarket performance transmissions are valved to alleviate such problems, and running a supplemental trans oil cooler is always a good idea.

ACT manufacturers a special High Pressure Valve (PN 17008) that allows the trans to see maximum oil pressure with a non-lockup-style converter, and they don’t recommend combining it with a lockup converter. TCI offers a wiring upgrade kit, which allows installation of a TH700 or TH200 with a lockup converter into any non-computer-controlled car. This wiring kit uses two sensors to control converter lockup at the proper time. The first sensor only engages the lockup clutch in Fourth gear, as a computer-controlled vehicle would. The other switch gets connected to a ported vacuum source and measures engine vacuum. This switch unlocks the converter if the engine is making less than 8 inches of manifold vacuum. So when the throttle is either wide open or completely closed, the converter clutch is unlocked, allowing converter slippage. This also acts as a safety to ensure that the converter will unlock before the vehicle comes to a stop.

Automatic Shifting Control

All of GM’s overdrive automatics use a cable connected to the throttle that tells the transmission when to shift. If this cable, called a Throttle Valve Cable (or TV cable for short), is connected incorrectly or misadjusted, the trans will shift too soon, too soft, too late, or not at all. Chevy High Performance outlined proper adjustment techniques for the TV cable back in the Mar. ’99 issue in a story titled “Hard Hittin’ Shiftin’” on page 66. If you’ve installed your overdrive and the trans won’t shift right, read that story and check out your adjustment. Holley, TCI, ACT, and GM all offer cable attachment brackets to facilitate TV cable connections to any carb. Also, there is no vacuum modulator used on the TH700/TH200, so you can plug the old line that ran from the base of the carb or intake manifold to the transmission.

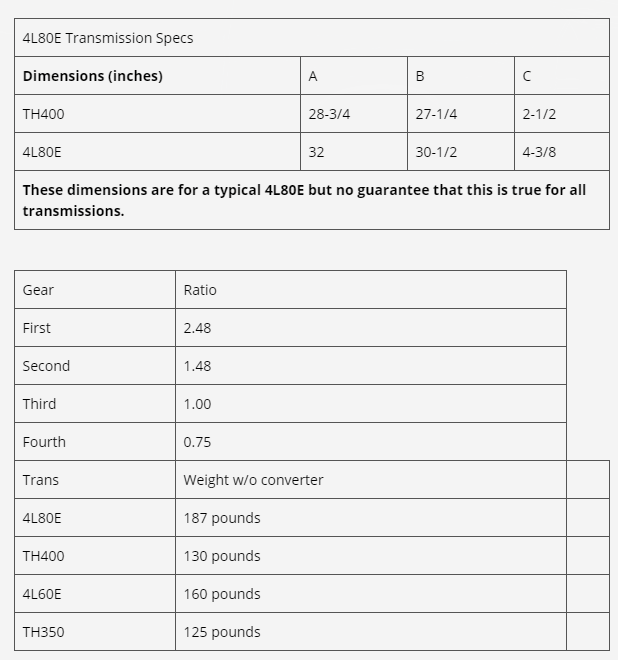

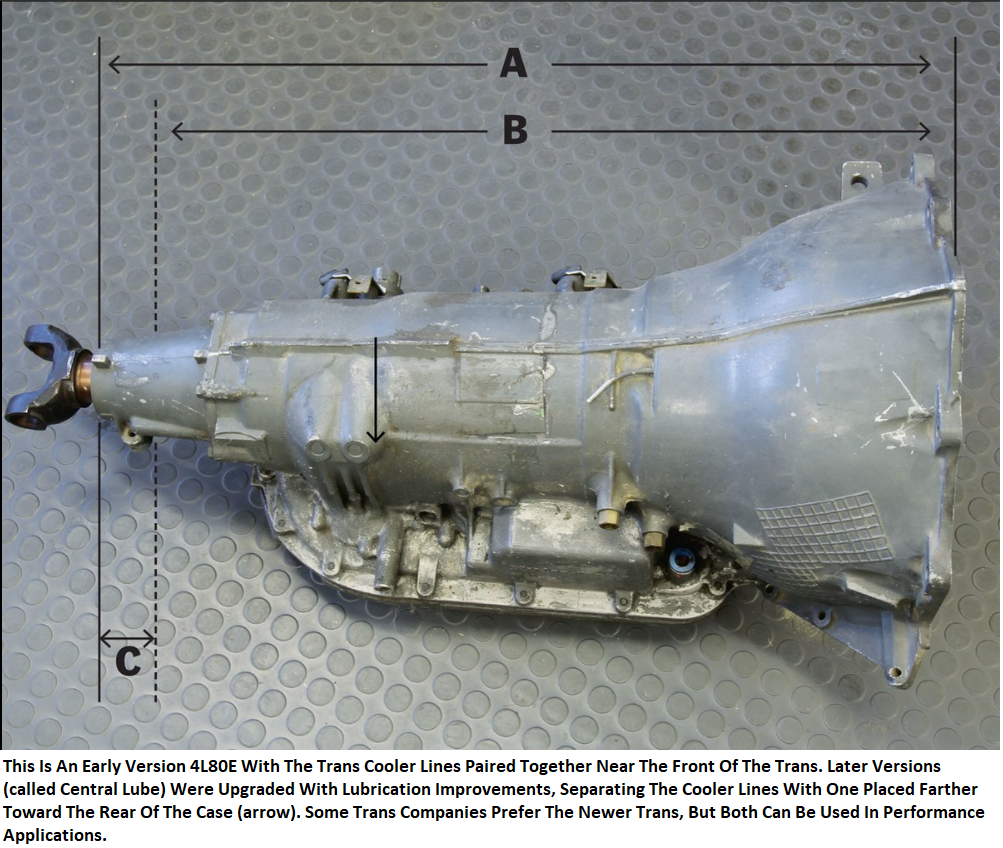

4L60-E And Its Big Brother The 4L80-E

It’s ironic that even though both of these strong overdrive transmissions come stock in all of GM’s automatic-equipped new cars and trucks, not many of them are finding their way into early performance musclecars. Perhaps that’s due to their weight and high initial cost. Or maybe it’s because they’re hard to find used in the scrap yards and many people don’t want to add a computer just to control the transmission. To make that task easier, JET Performance Products now offers a stand-alone computer-controlled system that will operate a 4L80-E transmission behind any carbureted or fuel-injected engine.

The 4L80-E Transconversion kit features its own computer with software that is custom-tuned to your vehicle’s specifications, providing the proper shift points, shift quality, and lockup torque converter function. Its wiring harness has a built-in diagnostic port that will allow the connection of the modern scanning electronics present in any Chevrolet dealership’s garage to track down and diagnose any transmission-related problems. The JET system will not interfere with any existing computer systems you may have already installed in your vehicle.

Manual Gearbox Swapping

This is where things get complicated—not because swapping an older four-speed or even a newer factory five-speed is all that difficult, but instead because there are so many different variations of manual transmissions floating around today that just knowing what you’ve got is a big step in the right direction. Chevy High Performancehas covered the transplant of GM’s T56 six-speed manual transmission into early Chevys in several stories (see “Get Six,” Sept. ’98, and “Get Six, Pt. II,” Feb. ’99; “Thrasher,” Oct. ’98; and “Trans Swapping Tech,” May ’99) so we highly recommend referring back to those issues for details concerning a T56 swap.

Several companies are now offering parts to help make swapping in a T56 a whole lot easier. One part is a completely new aftermarket T56 transmission assembly from National Drivetrain. All T56 transmissions installed in late-model cars use an electronic pickup to measure speed, but National’s T56 is designed to use the standard speedo cable and T5 manual transmission’s drive and driven gears. This T56 is a direct replacement for the weakling T5 trans that came stock in third-gen Camaros. Its case length and mounting pad are identical, and it features the same input/output spline count as the T5. It does require that the clutch be converted to a hydraulic pull-off design using a hydraulic master cylinder and remote fluid reservoir. Centerforce has come to the rescue and offers a clutch, flywheel, and pressure plate made to adapt this trans to early, two-piece rear-main-seal small-blocks.

Swapping any six-speed trans into your early Chevy iron is expensive and difficult, but it will give you the ultimate in shift control and cruising speed. There is much custom fabrication work involved in a six-speed swap as well as some additional high-performance hardware that you’ll need, including purchasing or fabricating a custom mounting bracket and modifying the stock clutch pedal for the hydraulic-clutch master cylinder, modifying or fabricating a complete transmission crossmember, relocating the shifter hole in the floor of the car, shortening the driveshaft and possibly changing its yoke, and even installing a small-diameter starter and having custom headers built for clearance. This may sound like a lot to swallow in one gulp, but one astute reader sent us a very detailed list outlining the modifications needed and the costs involved with making his T56 swap a reality. Roughly $3,000 later and after some very inventive engineering, he was rowing a T56 six-speed in his ’69 Camaro (see “Get Six, Pt. II,” Feb. ’99). We won’t say a T56 swap is a bad idea, but it’s not for the timid or frugal.

There are other aftermarket manual trans options available for the early Chevy crowd that won’t cost more than the down payment on a new car and are much easier to complete. One such swap involves installing a Richmond four-, five-, or even six-speed manual transmission. The Richmond gearboxes are unique in that they can be ordered with a variety of gear ratios to fit different driving styles. Only the Richmond four-speed trans is a direct-fit replacement for the ’71-and-later Muncie and Super T-10 transmissions using the same 26-spline input and 32-spline output shafts. Its overall dimensions are very close to either of those gearboxes, so the Richmond four-speed can be swapped into any car in which a ’71-and-later Muncie or Super T-10 was optional.

The Richmond five-speed is known as the Street Five-Speed and also uses a 26-spline input and 32-spline output shaft. It also has essentially the same dimensions externally as the pre-’71 Muncie and old T-10. The only modifications needed to install a Richmond five-speed in a pre-’71-Muncie– or T-10–equipped car would be moving the crossmember back approximately 2½ inches. The Richmond Street Five-Speed is not an overdrive trans and can only be ordered with a 1:1 Fifth-gear ratio.

Richmond’s bad-boy overdrive six-speed is a whole different beast from the rest of the six-speeds on the market. Some of the benefits of the Richmond six-speed is its light weight (108 pounds) and its ability to use a regular-style mechanical clutch and linkage from an early Chevrolet. The six-speed Richmond box is also available with either a 10- or 26-spline input shaft, and is an easy swap for early 10-spline–equipped Muncie and T-10 cars because its overall case length is equal to a Muncie or T-10. The rear mount on the Richmond six-speed will require a custom-fabricated crossmember—installed approximately 6 inches farther back—or it’s often possible to relocate the existing crossmember rearward. The new Richmond six-speed trans comes with its own six-speed shifter assembly that will require elongation of the shifter hole in the floor.

More can always be said and learned about any topic as vast as transmission swapping—a whole book could be written on this subject—but we’ll try to condense all the important information and pass it along to you as it becomes available. Feel free to write in with questions concerning your particular swap. We can’t answer your question directly, but we may address it in a future story, so stayed tuned.

Sources

Classic Industries

Huntington Beach, CA 92648

800-854-1280

www.classicindustries.com

TCI Automotive

Ashland, MS 38603

888-776-9824

www.tciauto.com

National Drivetrain

Chicago, IL 60609

866-427-0080

http://www.nationaldrivetrain.com/

ATI Performance Products

Baltimore, MD 21207

877-298-5039

www.atiracing.com

Centerforce Clutches

Prescott, AZ 86301

928-771-8422

http://www.centerforce.com

JET Performance Products

Huntington Beach , CA

800-535-1161

http://www.jetchip.com

Original Parts Group Inc. (OPGI)

Seal Beach, CA 90740

800-243-8355

www.opgi.com

Shiftworks

Rochester, NY 14625

585-383-0574

www.shiftworks.com

Advanced Adapters

Paso Robles, CA 93446

Year One

Tucker, GA 30085

800-932-7663

https://www.yearone.com

Auto-Rite Transmissions

Van Nuys, CA 91411

818-988-2167

Pioneer Performance Products Barnes Group Inc.

Meridian, MS 39301

ACT Performance Products (All Custom Transmission)

Van Nuys, CA 91406

Art Carr Performance Products\t

Reno, NV 89512

Denny’s Drive Shaft Service

Kenmore, NY 14217

Jaguars That Run (JTR)\t

Livermore, CA 94551

Westcoast Connections

Santa Rosa, CA 95407