Aaronvette said:Hi guys, need your advice if you please?

I have a new 383 short block with forged flat tops. decent Scat crank and rods.

I'm going to put my old Edelbrock RPM heads and Airgap on it.

My old setup in the 350 used the Performer RPM cam package

7102 cam .488/.510

Seat pressure - 110, open pressure at .490 - 285

My question is - can anyone recommened a flat tappet cam that's just slightly bigger than the Edelbrock cam, but one that I can use my Edelbrock valve springs with?

Just trying to save money where I can (vette resto is mounting up!) and if I can safety use my springs with say a comp cam and lifters then great, if not then no worries as I don't want to trash the engine. But surely it's all down to spring pressure?

Thoughts?

Many thanks, Aaron.

grumpyvette said:heres that edelbrock cam

http://www.jegs.com/i/Edelbrock/350...dkbfynngFcHFNNXScGu1AgAwad1uNPEvEgaAthO8P8HAQ

Performer RPM Camshaft Kit

1957-1986 Small Block Chevy 283-400ci

Lift: .488''/.510''

Duration @ .050: 234°/244°

Advertised Duration: 308°/318°

1500-6500 RPM Range

AS brian stated above,without knowing more about your application,all parts used, and matching drive train, picking a better cam match (WHICH MIGHT BE A BIT SMALLER OR LARGER)

would be nearly impossiable

Aaronvette said:My old 350 combo was -

Edelbrock RPM top end kit (68cc heads, milled)

10.5-1 compression (we can run higher compression here in England).

Flat tops.

Tremec TKO600RR 5 speed(2.87 first)

3.55 rear gears

Aluminium flywheel

The engine ran really strong up top, not much below 2500 but that was fine.

My question is quite specific -

As Edelbrock don't do a variety of cams does anyone know of a Comp Cam that is just a little bit bigger that the Edelbrock cam (bearing in mind the 383 can take a slightly bigger cam than a 350 for the same idle quality).

Also one that I can still use my Edelbrock valves prings/collets,

I can adjust DCR and SCR with different thickness gaskets but aiming for 10.5 SCR

I was looking at the 294s mechanical flat tappet from Comp but it needs valve springs with slightly higher pressure.

I'll see what my Dad has in his Camaro as that's a 383 and it is very quick,

realistically you need to step back and think through your goals and budget limitations,

and do some research on exactly how each component works,and how it works,

with the other components and in the process decide on a realistic goal,

that you can reasonably accomplish with the resources, tools and a bit of research, you have too work with.

IF YOUR SIMPLY TRYING TO GET A STOCK TPI CORVETTE ENGINE BACK IN SERVICE AS CHEAPLY AS YOU CAN?

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum. no head gasket will seal a badly machined or warped head or block

btw if youve managed to blow a head gasket on a 1986-91 TPI corvette with aluminum heads

the heads and block surfaces must be very carefully examined for damage or warping issues and if found those issues must be corrected, before any new head gaskets installed, over time steam can and will cut grooves in even cast iron blocks and rather easily in softer aluminum.

keep in mind coolant must have the anti-freeze ratio set at 50%water 50% antifreeze and be replaced at least every 4 years MAX to retain its anti corrosive additives

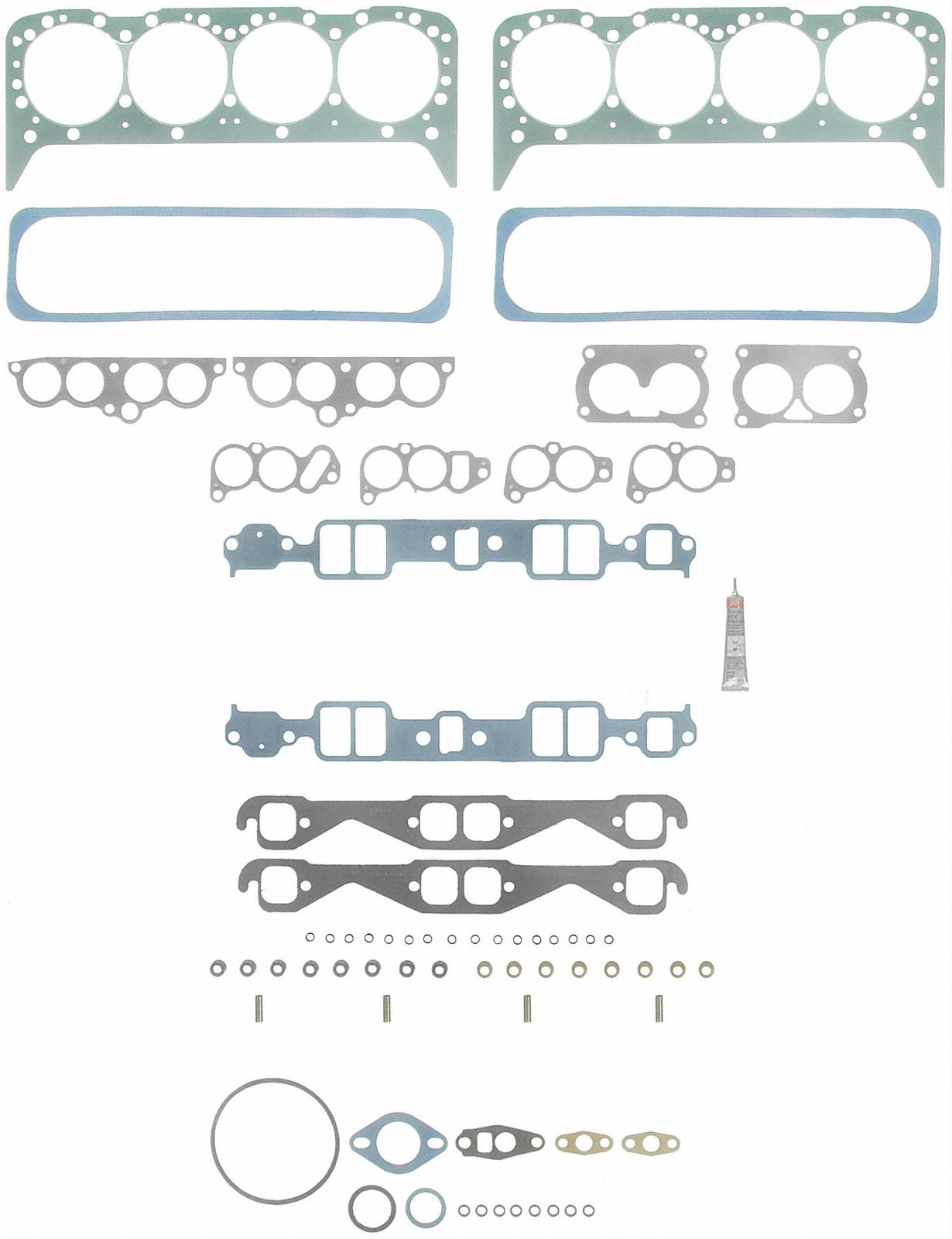

the stock 1986-91 tpi head gasket FELPRO HS7733pt9

http://garage.grumpysperformance.co...gine-to-match-the-cam-specs.11764/#post-55571

http://garage.grumpysperformance.com/index.php?threads/bits-of-383-info.38/page-2#post-61958

http://garage.grumpysperformance.co...on-building-a-383-sbc-stroker.428/#post-61899

http://garage.grumpysperformance.co...ty-thats-key-in-building-a-good-engine.11682/

http://garage.grumpysperformance.co...-rockers-and-the-pushrods-rub.198/#post-46839

http://garage.grumpysperformance.co...e-springs-and-setting-up-the-valve-train.181/

http://garage.grumpysperformance.com/index.php?threads/oil-system-mods-that-help.2187/

http://garage.grumpysperformance.co...ing-a-383-sbc-combo-planing.12168/#post-58778

because you seem to want too build a good deal more mid and upper rpm power,

IF I was building that engine Id certainly swap to a flat tappet SOLID LIFTER cam

similar to this (LINK BELOW)

and use a good set of 1.6:1 ratio roller rockers,

and yes it will require swapping to better valve springs and carefully checking all clearances.

and brians suggestion of a 4.11:1 rear gear ratio is a good idea.

https://www.summitracing.com/parts/crn-114681

WHY? well its easily going to allow you to control the valve train to at least 600rpm-800rpm higher,

in the rpm range so you increase the useable power band,

and that extra valve train stability at higher rpms,

that extends the power curve would certainly be a noticeable power advantage, over the current cam.

(that and the fact Ive built several very successful 383 engines using that cam)

AS always its the complete combo NOT just the cam you select that maters

why not call a few different cam companys and ask their tech guys

PHONE NUMBERS IN LINKS..

yes reading links will be helpful here

http://garage.grumpysperformance.com...sellection.82/

http://garage.grumpysperformance.com...59/#post-50014

http://garage.grumpysperformance.co...1-6-1-ratio-rockers-and-the-pushrods-rub.198/

http://garage.grumpysperformance.com...-problems.528/

http://garage.grumpysperformance.com/index.php?threads/mid-range-383-sbc-build.461/#post-1854

http://garage.grumpysperformance.com...lve-train.181/

http://garage.grumpysperformance.co...now-going-to-be-a-400.7804/page-18#post-35950

http://garage.grumpysperformance.com...learances.399/

Last edited: