enigma57

reliable source of info

Why swap a Pontiac engine into a '55 - '57 Chevy? Well, this engine swap began as a 'marriage of convenience', but it worked out well and this car was one of my favourite builds; fast, dependable and lots of fun to drive. Here's how it all came about......

In the mid to late 1970s, I was serving in the Navy aboard a submarine tender home ported at the Point Loma sub pier in San Diego. We worked on the subs (maintenance, repairs and installation of new equipment) during the height of the 'Cold War'.

To get around when we weren't at sea, I bought a 1965 GTO convertible from a guy on base for $300.00. He had driven it down from New London and it was a real beater...... The top material was non-existent, just a few shreds of tattered cloth hanging from the top bows. So I kept the top down and the tonneau cover snapped down. It seldom rained in Southern California, so no big deal, really. The frame...... What there was of it ...... Was so rusty from Connecticut winter road salt that it had corrosion stress cracks and the car flexed quite a bit. But it had a good running (nearly new) low mileage 1974 400 engine and a decent Muncie 4-speed and ran great. I had dreams of installing a new frame under the car and restoring the body one day.

But that was not to be. A guy driving a '66 Mustang tee-boned my ragtop on base and totalled it. I brought him 3 repair estimates and we settled the matter for $1,200.00. So I reluctantly pulled the engine and tranny and any other parts I thought I could use at the auto hobby shop on base and scrapped what was left. I lived aboard ship and over the next several months whenever we were in port, I put 3' X 5" cards under the windshield wipers of just about any car or truck in the base parking lot I thought I could swap my Pontiac engine into.

After months of no response, I got a call on our shop phone. A guy was mustering out. His hitch was up and he had a '56 Chevy stored at the auto hobby shop. The car hadn't run in years and he wanted to sell it before he hopped a plane for home the following week. I met him and checked out the car. The body and interiour were cherry. Straight, no rust, original black paint, 42,000 original miles. Steering and brakes were like new. But the drivetrain was shot. The car had been run hard on the strip and it had a hi-perf. 340 HP 327 with a thrown rod hanging out the side of the block, a decent (and very heavy) B&M cast-iron 4-speed hydramatic tranny originally from a GMC truck and a twisted right axle shaft. I bought it on the spot for $175.00. Later sold the engine, B&M tranny and rearend for $200.00 to a guy who was building up his '52 Chevy.

Many thanks to my wife for scanning these old photos. I lost many personal papers and photos during the 1983 hurricane (spinoff twister tore a huge chunk out of our roof and the rains destroyed most of the things I had stored in boxes in our den). I had sent these photos to my Aunt and about a year before she passed on, she returned them to me......

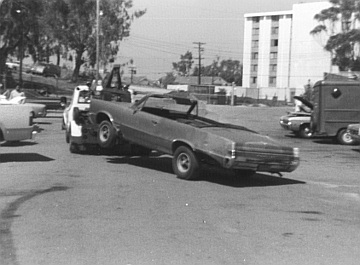

* The first photo and the others in this series were taken at the sub pier in San Diego, California in 1978 and 1979. It shows my wrecked '65 GTO ragtop being towed away from the auto hobby shop on base to the scrap yard. You cannot see it in the photo, but the frame was so rusted that it had corrosion cracks and was structurally unsound. And the body on the passenger side was smashed in about 18" from a collision involving the door all the way to the rear wheel opening. This car was a real beater, but I loved it. My '65 GTO had a Muncie M-21 4-speed transmission and a low mileage (under 12,000 miles) '74 Pontiac 400 engine with a '70 factory Q-jet intake and carb. I pulled the engine and tranny and installed them in a '56 Chevy 210 2-dr sedan body. Spring of 1978.

* The second photo is of myself and my '56 Chevy shortly after I got it running. Parked alongside the sub pier in San Diego. Nuke fast attack boat, diesel boat and sub tender in background. Summer of 1978.

* The third and fourth photos were taken on the other side of Point Loma on the road leading up to the Old Lighthouse and WW II gun emplacements. The factory chrome wheels were from a Chevelle. They were 15" X 7" wide and looked similar to Chevy truck rally wheels, except for being chromed and having 5 on 4-3/4" passenger car bolt pattern. G-60 15 radial tires at all four corners. I left the chassis and brakes stock except for adding the new power brake booster and master cylinder from my GTO and new heavy duty gas filled shocks, a late 1970s 1-1/4" diameter Trans Am Firebird front anti-sway bar and a 3/4" diameter rear anti-sway bar from a '76 Chrysler Cordoba. Differential was a 12-bolt posi from a '69 SS 396 Camaro. Rear brakes were stock '69 Camaro drum brakes. In the fifth photo, you can see the 12-bolt rear with chrome rear cover and the Cordoba rear anti-sway bar. Summer of 1979.

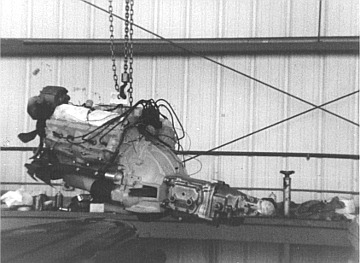

* The fifth photo shows the 400 Poncho engine on the hoist just before I installed it into the '56 Chevy. I kept the short block stock except for adding a 286 degree Sig Erson hydraulic cam, Isky anti-pump up lifters and double sprocket timing chain. I replaced the smog heads with a set of '69 Pontiac 428 cop car heads. These had smaller chambers to boost compression and the big ports and valves. Installed Erson valve springs matched to cam and located a set of Dorman replacement rocker arm nuts that allowed valves to be adjusted like a Chevy. This engine was a tight fit in the Chevy engine compartment. I scrounged a set of '68 Firebird right hand center dump exhaust manifolds and ran the right hand manifolds on both sides. Most of these had smallish 2" outlets, but I got lucky and found a pair of them with 2-1/4" outlets. Increased to 2-1/2" right after the flange and ran 2-1/2" duals. Note Ansen 'cast steel' safety bellhousing and M-21 Muncie tranny. Regarding engine mounts...... I bought a set of Hurst mounts. Hurst had a two-part mounting system for engine swaps consisting of engine brackets that bolted to the front of the engine and a second set of frame brackets. The rubber mounts were 1948 and earlier flathead Ford units. It was a good system. but when I went to install my engine, I found that the Hurst mounts positioned the big Pontiac engine rearward in the Chevy chassis and there was insufficient clearance to the firewall. Also placed the drivers side exhaust manifold too close to the '56 steering box and made the clutch linkage hard to set up. I ended up swapping the frame mounts right for left and when I had the engine exactly where I wanted it, I tack welded the frame mounts to the front crossmember, then pulled the engine and finished welding them in. Also installed the GTO transmission crossmember and rear mount. Summer of 1978.

* The sixth photo shows the 400 Pontiac engine in the '56 Chevy right after I fired it up for the first time to break in the cam. Initially, I ran the Q-jet and moved the original 3-core heavy duty '56 radiator forward to the '6-cylinder' position to allow for the longer engine and OEM '74 clutch fan. Note OEM Pontiac chrome valve covers and '65 GTO power brake booster and master cylinder. Tried every trick in the book, but couldn't keep the big Poncho cool. Finally had a huge crossflow radiator built utilizing Grand Prix side tanks and a 36" wide 4-tube desert cooler core and a combination of Pontiac and sheetmetal fanshrouding that I built for the Chevy...... Problem solved (see next two photos). Summer of 1978.

* The seventh and eighth photos show the engine after I installed a hand built Holley tri-power induction. I took a 1966 Pontiac tri-power cast-iron intake and adapted a set of new Dodge 440 6-pak carbs. These were the high performance carbs sold over the counter at MOPAR dealers back in the '70s. They were similar to AAR Cuda carbs in that they had the short square fuel bowls and the end carbs were mechanically actuated and had metering plates like the secondaries on double pumper 4bbl carbs. These were totally unlike the vacuum secondary carbs now available from MOPAR and they ran a lot better, too. To adapt them, I found a piece of scrap 1" thick aluminum plate and cut it down on a band saw to size. Then I laid out the holes and drilled the 12 holes that aligned with the Rochester bolt pattern of the manifold. I countersunk these and used stainless steel countersunk machine screws to fasten the plate to the iron intake. Next, I laid out the 12 holes for the wider Holley bolt pattern and drilled and tapped them. Then I laid out the 6 holes for the larger Holley throttle bores and carefully drilled them using progressively larger bits and carefully drilling down through both the aluminum plate and the cast-iron carb mounting flanges below so that there was no mismatch, only smooth throttle bore openings beneath the Holley carbs. Between the Holley carb base plates and the aluminum plate, I sandwiched 3 Ford 2bbl water heated/cooled carb base plates. I plumbed water from the front of the intake manifold through all 3 and from the last back to the heater core. The passenger side head of the Pontiac engine had a fitting pressed into the back of the head (coolant passage) that had a 90 degree bend and hose connection. I fitted a short piece of heater hose to this and connected it to the remaining heater core connection. This did wonders for drivability and cleaned up the top of the engine as well, eliminating the long run of heater hose that originally ran from the front of the engine all the way back to the firewall. I adapted the OEM Pontiac mechanical progressive throttle linkage to the Holley carbs. It is painted red and you can make it out in the photos. The air cleaner is hand made. The oval filter element is from a 1970 Datsun 240Z. I made an aluminum base plate with 3 short 'D'-shaped pieces to raise it high enough above the carbs so that it wouldn't block the fuel bowl vents. It is sealed to the carb air inlets using rubber 'O'rings stretched over the 'D'-shaped air horns. The top piece is made from brushed stainless steel. Ran great and jetting was right on. The only problem I ran into was fuel starvation when I kicked in the secondary (end) carbs. In the photos, you will note that I initially ran the fuel line in thickwall 3/8" OD stainless tubing. What I had to do is to remove that and fab a fuel log similar to those used in the early '60s OEM Ford 406 Holley tri-power setups. I built it from a piece of 1" OD stainless steel pipe. Capped the ends and drilled the front for a stainless 3/8" pipe nipple (supply) and drilled the sides for 3 3/8" pipe nipples (aligned towards the carbs and connected to the fuel inlets with fuel hose and hose clamps). I welded all 4 pipe nipples in place and made up 2 stainless tabs with 3/8" diameter holes. These held the fuel log in place outboard of the carbs pretty much in line with the restrictive stainless tubing I had removed. After this was installed, I pulled the gas tank and installed a new 3/8" fuel pickup and sending unit for a '57 dual 4bbl engine and replaced the original 5/16" fuel line with new 3/8" tubing from the tank to the fuel pump. I retained the OEM Pontiac mechanical fuel pump and along with the larger 3/8" fuel line and the added volume of the fuel log, no more problems with fuel starvation. Note taller Mickey Thompson aluminum valve covers. These were a tight fit, but they just cleared the GTO power brake booster and firewall mounted battery box in my '56 Chevy. Of yeah, one last thing. I was running a 3.73 posi rear along with a 2.20 low gear (close ratio gearset) in the Muncie tranny. With the lumpy cam, you'd think that this gearing would be just right. But the big Pontiac mill made so much low end torque that unless you were getting started from a dead stop up an incline or racing, 1st gear was nearly useless and either you took off in 2nd gear on level ground or short-shifted from 1st into 2nd right after taking off. So I swapped in a 3.07 highway gear and that worked out just right. Yes, contrary to all that I've been taught, but the big Poncho loved it even with the cam. Out on the road, if you eased into the throttle, you could run up to 90 MPH on the center 2bbl before the end carbs began to tip in. Top speed was around 138 MPH. Mileage on the open road cruising on level ground at 70 - 75 MPH in high gear was 18.5 MPG. Summer of 1979.

Best regards,

Harry

In the mid to late 1970s, I was serving in the Navy aboard a submarine tender home ported at the Point Loma sub pier in San Diego. We worked on the subs (maintenance, repairs and installation of new equipment) during the height of the 'Cold War'.

To get around when we weren't at sea, I bought a 1965 GTO convertible from a guy on base for $300.00. He had driven it down from New London and it was a real beater...... The top material was non-existent, just a few shreds of tattered cloth hanging from the top bows. So I kept the top down and the tonneau cover snapped down. It seldom rained in Southern California, so no big deal, really. The frame...... What there was of it ...... Was so rusty from Connecticut winter road salt that it had corrosion stress cracks and the car flexed quite a bit. But it had a good running (nearly new) low mileage 1974 400 engine and a decent Muncie 4-speed and ran great. I had dreams of installing a new frame under the car and restoring the body one day.

But that was not to be. A guy driving a '66 Mustang tee-boned my ragtop on base and totalled it. I brought him 3 repair estimates and we settled the matter for $1,200.00. So I reluctantly pulled the engine and tranny and any other parts I thought I could use at the auto hobby shop on base and scrapped what was left. I lived aboard ship and over the next several months whenever we were in port, I put 3' X 5" cards under the windshield wipers of just about any car or truck in the base parking lot I thought I could swap my Pontiac engine into.

After months of no response, I got a call on our shop phone. A guy was mustering out. His hitch was up and he had a '56 Chevy stored at the auto hobby shop. The car hadn't run in years and he wanted to sell it before he hopped a plane for home the following week. I met him and checked out the car. The body and interiour were cherry. Straight, no rust, original black paint, 42,000 original miles. Steering and brakes were like new. But the drivetrain was shot. The car had been run hard on the strip and it had a hi-perf. 340 HP 327 with a thrown rod hanging out the side of the block, a decent (and very heavy) B&M cast-iron 4-speed hydramatic tranny originally from a GMC truck and a twisted right axle shaft. I bought it on the spot for $175.00. Later sold the engine, B&M tranny and rearend for $200.00 to a guy who was building up his '52 Chevy.

Many thanks to my wife for scanning these old photos. I lost many personal papers and photos during the 1983 hurricane (spinoff twister tore a huge chunk out of our roof and the rains destroyed most of the things I had stored in boxes in our den). I had sent these photos to my Aunt and about a year before she passed on, she returned them to me......

* The first photo and the others in this series were taken at the sub pier in San Diego, California in 1978 and 1979. It shows my wrecked '65 GTO ragtop being towed away from the auto hobby shop on base to the scrap yard. You cannot see it in the photo, but the frame was so rusted that it had corrosion cracks and was structurally unsound. And the body on the passenger side was smashed in about 18" from a collision involving the door all the way to the rear wheel opening. This car was a real beater, but I loved it. My '65 GTO had a Muncie M-21 4-speed transmission and a low mileage (under 12,000 miles) '74 Pontiac 400 engine with a '70 factory Q-jet intake and carb. I pulled the engine and tranny and installed them in a '56 Chevy 210 2-dr sedan body. Spring of 1978.

* The second photo is of myself and my '56 Chevy shortly after I got it running. Parked alongside the sub pier in San Diego. Nuke fast attack boat, diesel boat and sub tender in background. Summer of 1978.

* The third and fourth photos were taken on the other side of Point Loma on the road leading up to the Old Lighthouse and WW II gun emplacements. The factory chrome wheels were from a Chevelle. They were 15" X 7" wide and looked similar to Chevy truck rally wheels, except for being chromed and having 5 on 4-3/4" passenger car bolt pattern. G-60 15 radial tires at all four corners. I left the chassis and brakes stock except for adding the new power brake booster and master cylinder from my GTO and new heavy duty gas filled shocks, a late 1970s 1-1/4" diameter Trans Am Firebird front anti-sway bar and a 3/4" diameter rear anti-sway bar from a '76 Chrysler Cordoba. Differential was a 12-bolt posi from a '69 SS 396 Camaro. Rear brakes were stock '69 Camaro drum brakes. In the fifth photo, you can see the 12-bolt rear with chrome rear cover and the Cordoba rear anti-sway bar. Summer of 1979.

* The fifth photo shows the 400 Poncho engine on the hoist just before I installed it into the '56 Chevy. I kept the short block stock except for adding a 286 degree Sig Erson hydraulic cam, Isky anti-pump up lifters and double sprocket timing chain. I replaced the smog heads with a set of '69 Pontiac 428 cop car heads. These had smaller chambers to boost compression and the big ports and valves. Installed Erson valve springs matched to cam and located a set of Dorman replacement rocker arm nuts that allowed valves to be adjusted like a Chevy. This engine was a tight fit in the Chevy engine compartment. I scrounged a set of '68 Firebird right hand center dump exhaust manifolds and ran the right hand manifolds on both sides. Most of these had smallish 2" outlets, but I got lucky and found a pair of them with 2-1/4" outlets. Increased to 2-1/2" right after the flange and ran 2-1/2" duals. Note Ansen 'cast steel' safety bellhousing and M-21 Muncie tranny. Regarding engine mounts...... I bought a set of Hurst mounts. Hurst had a two-part mounting system for engine swaps consisting of engine brackets that bolted to the front of the engine and a second set of frame brackets. The rubber mounts were 1948 and earlier flathead Ford units. It was a good system. but when I went to install my engine, I found that the Hurst mounts positioned the big Pontiac engine rearward in the Chevy chassis and there was insufficient clearance to the firewall. Also placed the drivers side exhaust manifold too close to the '56 steering box and made the clutch linkage hard to set up. I ended up swapping the frame mounts right for left and when I had the engine exactly where I wanted it, I tack welded the frame mounts to the front crossmember, then pulled the engine and finished welding them in. Also installed the GTO transmission crossmember and rear mount. Summer of 1978.

* The sixth photo shows the 400 Pontiac engine in the '56 Chevy right after I fired it up for the first time to break in the cam. Initially, I ran the Q-jet and moved the original 3-core heavy duty '56 radiator forward to the '6-cylinder' position to allow for the longer engine and OEM '74 clutch fan. Note OEM Pontiac chrome valve covers and '65 GTO power brake booster and master cylinder. Tried every trick in the book, but couldn't keep the big Poncho cool. Finally had a huge crossflow radiator built utilizing Grand Prix side tanks and a 36" wide 4-tube desert cooler core and a combination of Pontiac and sheetmetal fanshrouding that I built for the Chevy...... Problem solved (see next two photos). Summer of 1978.

* The seventh and eighth photos show the engine after I installed a hand built Holley tri-power induction. I took a 1966 Pontiac tri-power cast-iron intake and adapted a set of new Dodge 440 6-pak carbs. These were the high performance carbs sold over the counter at MOPAR dealers back in the '70s. They were similar to AAR Cuda carbs in that they had the short square fuel bowls and the end carbs were mechanically actuated and had metering plates like the secondaries on double pumper 4bbl carbs. These were totally unlike the vacuum secondary carbs now available from MOPAR and they ran a lot better, too. To adapt them, I found a piece of scrap 1" thick aluminum plate and cut it down on a band saw to size. Then I laid out the holes and drilled the 12 holes that aligned with the Rochester bolt pattern of the manifold. I countersunk these and used stainless steel countersunk machine screws to fasten the plate to the iron intake. Next, I laid out the 12 holes for the wider Holley bolt pattern and drilled and tapped them. Then I laid out the 6 holes for the larger Holley throttle bores and carefully drilled them using progressively larger bits and carefully drilling down through both the aluminum plate and the cast-iron carb mounting flanges below so that there was no mismatch, only smooth throttle bore openings beneath the Holley carbs. Between the Holley carb base plates and the aluminum plate, I sandwiched 3 Ford 2bbl water heated/cooled carb base plates. I plumbed water from the front of the intake manifold through all 3 and from the last back to the heater core. The passenger side head of the Pontiac engine had a fitting pressed into the back of the head (coolant passage) that had a 90 degree bend and hose connection. I fitted a short piece of heater hose to this and connected it to the remaining heater core connection. This did wonders for drivability and cleaned up the top of the engine as well, eliminating the long run of heater hose that originally ran from the front of the engine all the way back to the firewall. I adapted the OEM Pontiac mechanical progressive throttle linkage to the Holley carbs. It is painted red and you can make it out in the photos. The air cleaner is hand made. The oval filter element is from a 1970 Datsun 240Z. I made an aluminum base plate with 3 short 'D'-shaped pieces to raise it high enough above the carbs so that it wouldn't block the fuel bowl vents. It is sealed to the carb air inlets using rubber 'O'rings stretched over the 'D'-shaped air horns. The top piece is made from brushed stainless steel. Ran great and jetting was right on. The only problem I ran into was fuel starvation when I kicked in the secondary (end) carbs. In the photos, you will note that I initially ran the fuel line in thickwall 3/8" OD stainless tubing. What I had to do is to remove that and fab a fuel log similar to those used in the early '60s OEM Ford 406 Holley tri-power setups. I built it from a piece of 1" OD stainless steel pipe. Capped the ends and drilled the front for a stainless 3/8" pipe nipple (supply) and drilled the sides for 3 3/8" pipe nipples (aligned towards the carbs and connected to the fuel inlets with fuel hose and hose clamps). I welded all 4 pipe nipples in place and made up 2 stainless tabs with 3/8" diameter holes. These held the fuel log in place outboard of the carbs pretty much in line with the restrictive stainless tubing I had removed. After this was installed, I pulled the gas tank and installed a new 3/8" fuel pickup and sending unit for a '57 dual 4bbl engine and replaced the original 5/16" fuel line with new 3/8" tubing from the tank to the fuel pump. I retained the OEM Pontiac mechanical fuel pump and along with the larger 3/8" fuel line and the added volume of the fuel log, no more problems with fuel starvation. Note taller Mickey Thompson aluminum valve covers. These were a tight fit, but they just cleared the GTO power brake booster and firewall mounted battery box in my '56 Chevy. Of yeah, one last thing. I was running a 3.73 posi rear along with a 2.20 low gear (close ratio gearset) in the Muncie tranny. With the lumpy cam, you'd think that this gearing would be just right. But the big Pontiac mill made so much low end torque that unless you were getting started from a dead stop up an incline or racing, 1st gear was nearly useless and either you took off in 2nd gear on level ground or short-shifted from 1st into 2nd right after taking off. So I swapped in a 3.07 highway gear and that worked out just right. Yes, contrary to all that I've been taught, but the big Poncho loved it even with the cam. Out on the road, if you eased into the throttle, you could run up to 90 MPH on the center 2bbl before the end carbs began to tip in. Top speed was around 138 MPH. Mileage on the open road cruising on level ground at 70 - 75 MPH in high gear was 18.5 MPG. Summer of 1979.

Best regards,

Harry