now theres the rather obvious advantage, that a taller valve cover has that allows you more room under most tall valve covers for roller rockers and in many cases even stud girdles, and in many cases the look of the taller covers makes the engine look more impressive, but many people don,t realize that use of those roller rockers tends to reduce friction and that reduced friction tends to lower oil temps.

and that stud girdles that typically won,t fit without tall valve covers ,significantly strengthen and stiffen the stud rocker style valve train.

BUT MANY PEOPLE DON,T REALIZE THAT THE TALLER COVERS ALSO SUPPLY MORE OIL COOLING SURFACE AREA, TO PARTIALLY REDUCE OR DISPERSE HEATED OIL TEMPS

oil temps on a performance engine frequently run in the 230-245F range as the valve train is a significant source of heat, and while the engine compartmental is hardly (COOL) its common for air temps around the valve covers to be slightly lower than the oil temps inside the valve covers allowing oil sprayed from the rockers to flow in sheets at high rpms over the inner valve covers surface and transmit heat outward to the air flowing around the engine.

now ID bet 90% plus of the guys never thought about that but simple use of an infrared temp gun will show you its true as will a simple test of swapping back and forth between different valve cover designs, its COMMON for tall cast aluminum valve covers for example to drop your oil temps a few degrees over shorter stock versions

THERES VALVE COVER SPACERS IF YOU JUST NEED TO INCREASE HEIGHT ON YOUR CURRENT VALVE COVERS TO GAIN CLEARANCE FOR ROLLER ROCKERS ETC>

http://www.jegs.com/i/B-B/128/63910/100 ... tId=747514

or obviously a wide selection of taller valve cover designs

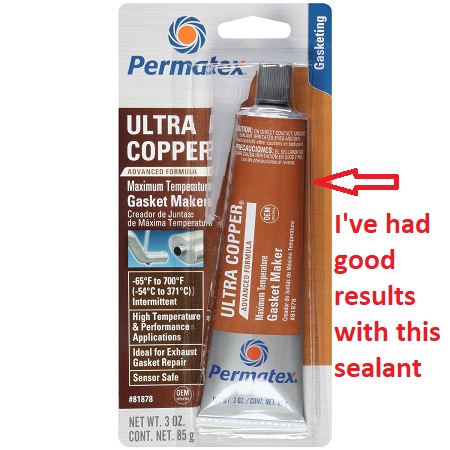

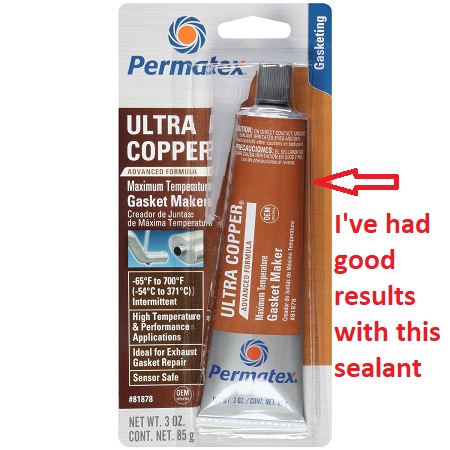

For more information, check out www.permatex.com. You’ll find product specs, technical data sheets, and instructional videos to help you learn more about which Permatex Gasket Maker is right for your job.

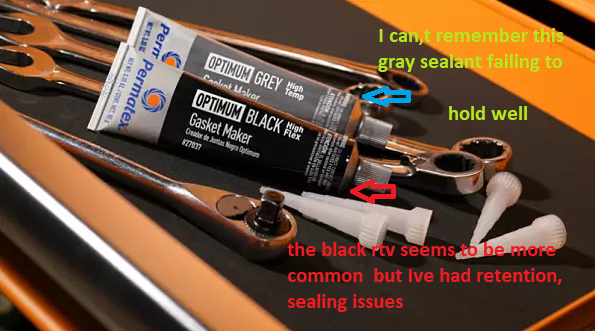

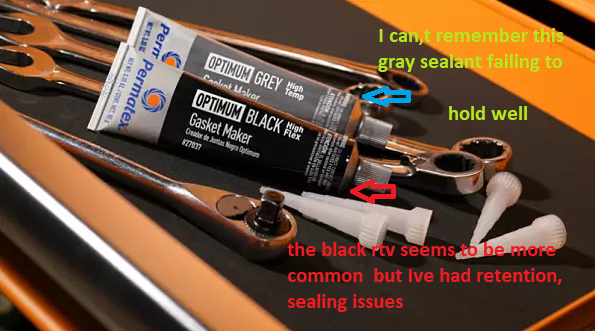

In my experience, the black rtv works ok,

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

truthfully all three sealants work in a wide range odf applications, they work , best,if the surfaces were cleaned and de-greased prior to the sealants application,

of the sealant you select, so I doubt you,ll have any issues,

given a choice, Id have selected the high temp copper or as a back-up the high temp gray,

but like I stated I doubt any of the three would fail to do the job.

the key is proper surface, prep, de- greasing and cleaning, prior to the sealant application, and not over tightening the bolts.

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

related info

http://garage.grumpysperformance.co...s-stamped-steel-valve-covers.4116/#post-10935

viewtopic.php?f=52&t=2875&p=7458&hilit=girdle#p7458

viewtopic.php?f=32&t=1683&p=4098&hilit=+rockers+girdle#p4098

viewtopic.php?f=52&t=126&p=1193&hilit=+rockers+girdle#p1193

viewtopic.php?f=80&t=1288&p=2757&hilit=chrome+cover#p2757

viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

viewtopic.php?f=52&t=2746&hilit=studs+rocker

viewtopic.php?f=52&t=663&p=911&hilit=+rockers+girdle#p911

viewtopic.php?f=52&t=181&p=215&hilit=+rockers+girdle#p215

IF YOU HAPPEN TO FIND AN OLD SET AT A YARD SALE AT A GOOD PRICE YOU CAN MAKE A GOOD SET OF VALVE ADJUSTMENT OIL GUARD VALVE COVERS OUT OF THEM

heres a short set, so modified but a tall set, like these below once milled, for center rocker stud & wrench clearance, will work far better

occasionally you'll find that clearance issues with some engines and taller valve covers force you to use some fabrication skill to get required clearances

and that stud girdles that typically won,t fit without tall valve covers ,significantly strengthen and stiffen the stud rocker style valve train.

BUT MANY PEOPLE DON,T REALIZE THAT THE TALLER COVERS ALSO SUPPLY MORE OIL COOLING SURFACE AREA, TO PARTIALLY REDUCE OR DISPERSE HEATED OIL TEMPS

oil temps on a performance engine frequently run in the 230-245F range as the valve train is a significant source of heat, and while the engine compartmental is hardly (COOL) its common for air temps around the valve covers to be slightly lower than the oil temps inside the valve covers allowing oil sprayed from the rockers to flow in sheets at high rpms over the inner valve covers surface and transmit heat outward to the air flowing around the engine.

now ID bet 90% plus of the guys never thought about that but simple use of an infrared temp gun will show you its true as will a simple test of swapping back and forth between different valve cover designs, its COMMON for tall cast aluminum valve covers for example to drop your oil temps a few degrees over shorter stock versions

THERES VALVE COVER SPACERS IF YOU JUST NEED TO INCREASE HEIGHT ON YOUR CURRENT VALVE COVERS TO GAIN CLEARANCE FOR ROLLER ROCKERS ETC>

http://www.jegs.com/i/B-B/128/63910/100 ... tId=747514

or obviously a wide selection of taller valve cover designs

For more information, check out www.permatex.com. You’ll find product specs, technical data sheets, and instructional videos to help you learn more about which Permatex Gasket Maker is right for your job.

In my experience, the black rtv works ok,

but the high heat gray or copper gasket sealant has always worked a bit better

I prefer this for most of the jobs where silicone type gasket sealants get used like intake gaskets and valve cover gaskets

http://garage.grumpysperformance.com/index.php?threads/sealants-and-threads.805/#post-71928

truthfully all three sealants work in a wide range odf applications, they work , best,if the surfaces were cleaned and de-greased prior to the sealants application,

of the sealant you select, so I doubt you,ll have any issues,

given a choice, Id have selected the high temp copper or as a back-up the high temp gray,

but like I stated I doubt any of the three would fail to do the job.

the key is proper surface, prep, de- greasing and cleaning, prior to the sealant application, and not over tightening the bolts.

On oil pans I prefer studs, and an oil pan back plate

you might want to Use with P/N 12553058 RH and P/N 12553059 LH oil pan reinforcement plates to distribute the bolt stress on the oil pan rail for 1985 and earlier oil pans P/N 14088501 (LH) and P/N 14088502 (RH).1986 and newer

related info

http://garage.grumpysperformance.co...s-stamped-steel-valve-covers.4116/#post-10935

viewtopic.php?f=52&t=2875&p=7458&hilit=girdle#p7458

viewtopic.php?f=32&t=1683&p=4098&hilit=+rockers+girdle#p4098

viewtopic.php?f=52&t=126&p=1193&hilit=+rockers+girdle#p1193

viewtopic.php?f=80&t=1288&p=2757&hilit=chrome+cover#p2757

viewtopic.php?f=44&t=579&p=743&hilit=+infrared+tuning#p743

viewtopic.php?f=52&t=2746&hilit=studs+rocker

viewtopic.php?f=52&t=663&p=911&hilit=+rockers+girdle#p911

viewtopic.php?f=52&t=181&p=215&hilit=+rockers+girdle#p215

IF YOU HAPPEN TO FIND AN OLD SET AT A YARD SALE AT A GOOD PRICE YOU CAN MAKE A GOOD SET OF VALVE ADJUSTMENT OIL GUARD VALVE COVERS OUT OF THEM

heres a short set, so modified but a tall set, like these below once milled, for center rocker stud & wrench clearance, will work far better

occasionally you'll find that clearance issues with some engines and taller valve covers force you to use some fabrication skill to get required clearances

Last edited by a moderator: