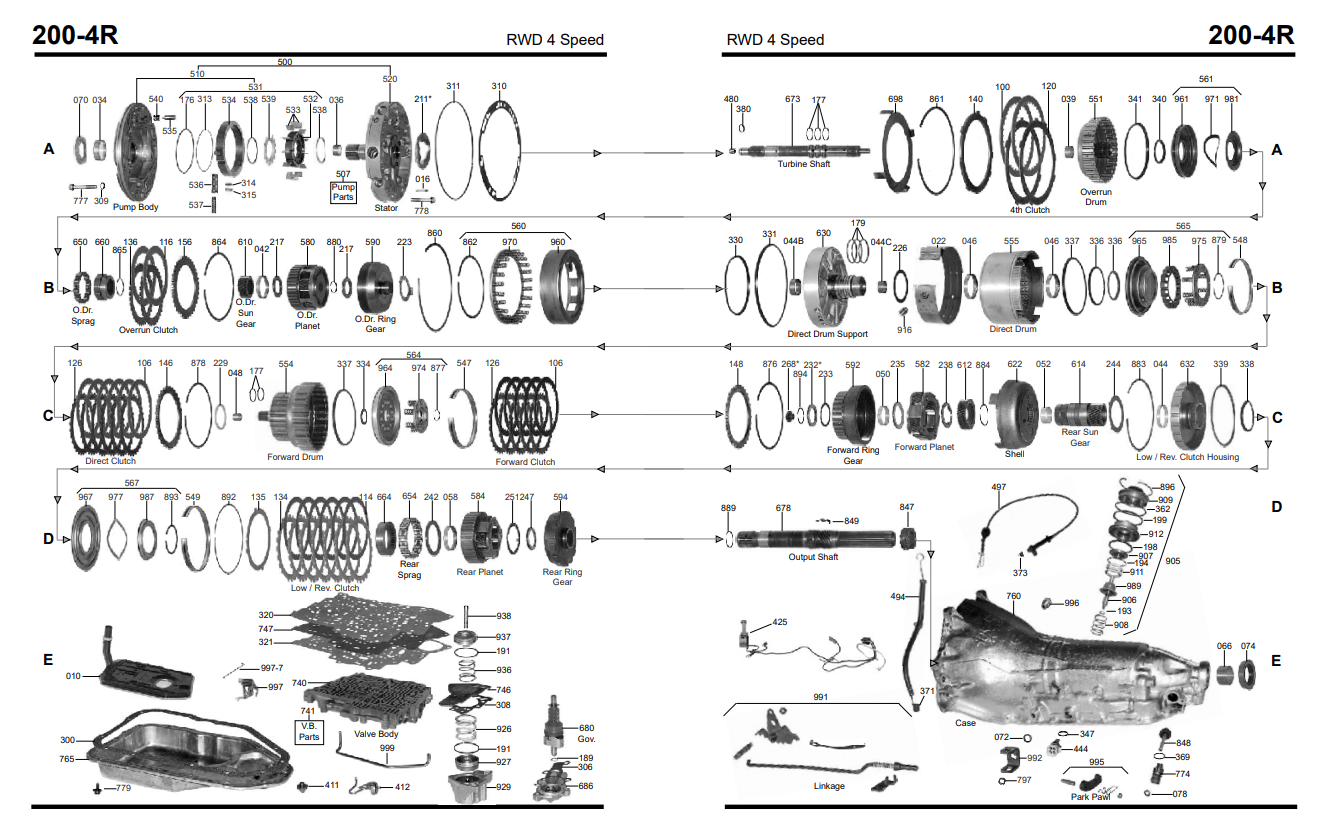

Been working on adding a cooler for trans. Made a couple brackets that attach to the

underside of the frame and to the Derale #51908, 19 row, stacked plate cooler. I know

it's going to be marginal, but it's all I can fit in there I thought. Now I know I could go

taller, so maybe the next up would be the 25 row cooler. That would take me from

37,000 BTU to 46,000 BTU cooler or 24% better cooling.

With the cooler in close proximity to the trans connectors, I needed connectors that

pointed at each other. Just not enough space to make several sharp bends. They are

expensive, but the swivel type 90° AN connectors were just what I needed.

underside of the frame and to the Derale #51908, 19 row, stacked plate cooler. I know

it's going to be marginal, but it's all I can fit in there I thought. Now I know I could go

taller, so maybe the next up would be the 25 row cooler. That would take me from

37,000 BTU to 46,000 BTU cooler or 24% better cooling.

With the cooler in close proximity to the trans connectors, I needed connectors that

pointed at each other. Just not enough space to make several sharp bends. They are

expensive, but the swivel type 90° AN connectors were just what I needed.