if you look at the facts here,

the 200r4 did not fail under stress, or during a race or hard launch, or towing a heavy load or on a long trip in country with lots of hills to climb, and the cars weight and lack of decent traction acts like a fail/safe or fuse,

limiting any shock loads as the tires are much more likely to loose traction before the transmission start's puking its internals.

due to not being able to handle the current engines power / torque .

no, from all the evidence, that was previously posted,

the transmission simply had failed because the shifter / gear selection controls were not properly adjusted prior to starting the engine,

or the cooling lines and coolant level and type of transmission fluid was not functioning correctly.

this is far more common that you might think, and as a result I suggest a good amount of time spent in researching proper cooling accessories, like trans fluid coolers and linkage adjustment be done prior to starting any new engine & trans install.

Ricks doing an exemplary job in refurbishing the 200r4 transmission, and its cooling lines and shifter linkages etc.

and if its properly re-installed and adjusted prior... to that engine being restarted,

I doubt Ricks going to have issues, and now that hes found a source for even more replacement parts and has gained considerable experience rebuilding ,

that 200r4 I would be rather foolish to not give the new re-built transmission a second chance at providing the car with a long happy life.

now just as obviously, if the engine does prove to overwhelm the transmissions ability to provide the car with dependable power transfer characteristics,

looking into how and why components should be upgraded would be a sensible route to look into further.

personally I don,t think Rick's likely to have continuing issues simply because the same basic 200r4 transmission ,

has been used behind the turbo v6 engines an significantly heavier cars with similar horse power.

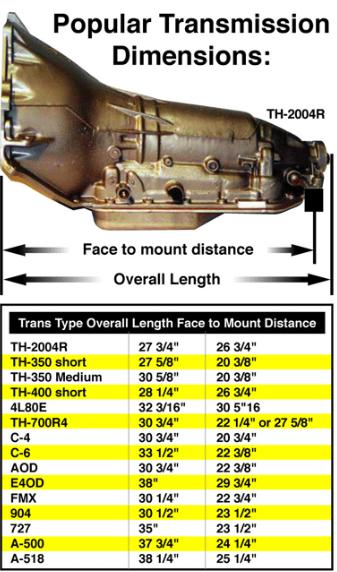

the 200r4 is a well proven transmission, with an over drive top gear ratio, which is similar the the more common 700r4 used in corvettes, but its more easily swapped with the th350 than the 700r4 .

obviously time and experience and some research into upgrades if it becomes an issue later won,t hurt either.

http://garage.grumpysperformance.co...hing-the-drive-train-to-the-engine-combo.741/