It's time to get this party started! Last night I picked up some of my parts, the only thing left to come in, is the Mahle piston and rings. This is just the first order, mostly the things I need right now to get started. It's been over ten years since I've driven this car and I am SOOO ready to get it back on the street.

Some tools are coming in today, such as:

- KD 3/8" (10-100 ftlbs)Torque Wrench

http://www.toolsource.com/micrometer-to ... 93417.html

- 6" long mandrel for the 1/4" Die Grinder to use cartridge rolls.

http://www.abrasivesupply.com/Standard_ ... /cm9xl.htm

- I already have these cartridge rolls, for the mandrel above.

- Unitized 6" Wheel for the bench grinder. Used for deburring and polishing.

http://www.abrasivesupply.com/ProductDe ... ode=882178

I guess nothing is perfect, the die grinder should take care of these imperfection. Looks like they used a chisel to knock some casting slag out.

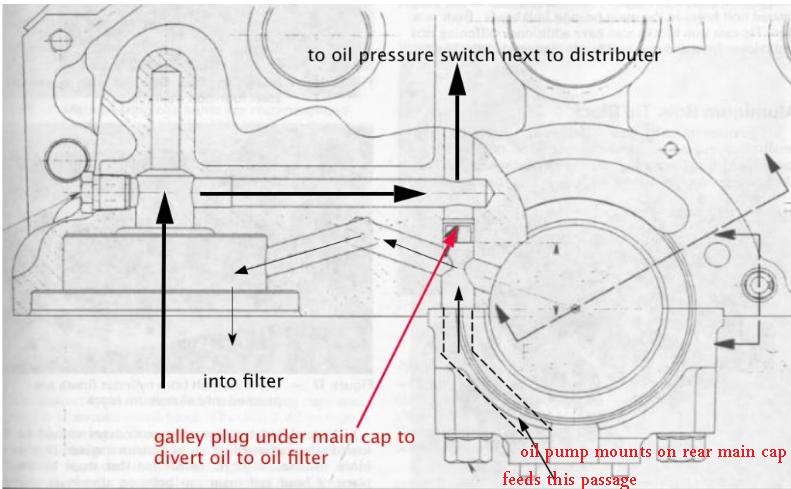

I cut off the mount from my stock oil pump to use for a template on the rear main cap. I suppose the Melling 10552 oil pump will fit the same. Something to think about!

Some tools are coming in today, such as:

- KD 3/8" (10-100 ftlbs)Torque Wrench

http://www.toolsource.com/micrometer-to ... 93417.html

- 6" long mandrel for the 1/4" Die Grinder to use cartridge rolls.

http://www.abrasivesupply.com/Standard_ ... /cm9xl.htm

- I already have these cartridge rolls, for the mandrel above.

- Unitized 6" Wheel for the bench grinder. Used for deburring and polishing.

http://www.abrasivesupply.com/ProductDe ... ode=882178

I guess nothing is perfect, the die grinder should take care of these imperfection. Looks like they used a chisel to knock some casting slag out.

I cut off the mount from my stock oil pump to use for a template on the rear main cap. I suppose the Melling 10552 oil pump will fit the same. Something to think about!

Last edited: