First, i dont think this is a water pump/heat issue.. that would show up on the temperature gauge...(unless its defective..)

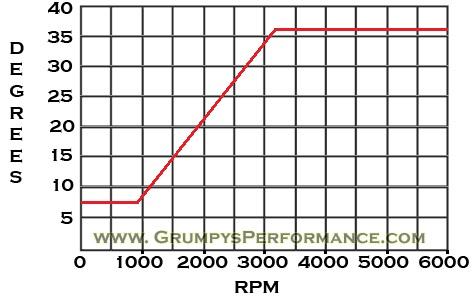

Id check the ignition timing and advance curve and fuel delivery(follow grumpy's advice)... before going too far.

Am surprized no one mentionned a leaking intake gasket.. this seem to be a common place for oil(and vacuum) leak on sbc..

I run about the same 8.3:! DCR and a much higher effective/Boost CR (11.5:1) on 91 octane... i can guarantee you there is NO detonation(pulled the heads 2 week ago).. i do run a rich fuel mixture right from the idle and heavy pump shot and slighly less total ignition advance with cold plugs

.

Steady knock sound like too much ignition advance or too lean A/F ratio(unless something else is causing it like deposit/hot spot).

For your case here is what am thinking:

First give us more info(while am not very experienced am sure it will help others)

Is the oil consumtion all the time or only when its knocking/detonating?..(probably sound stupid,, let's reformulate below)

Did it reduce its oil consumption since you increased the octane/stopped the detonation problem?

Do it look to be happening(the detonation and oil consumption) to every cylinder or just one or a few of them? (how do the spark plug look?)

Was the engine (re-)tuned on a dyno?(i think you said it was going to a few week ago) maby they did a bad job..

Stupid question again..

How do the exhaust smell?(any smell of burning oil?) No blue smoke at all? (get someone to follow you in another car behind)

what about the 400 steam holes? did you need them and forgot?

Are you sure you have the correct spark plug heat range? from the past picture, they seem hot a little to me for a race engine(and a bit on the lean side too..).. maby its just me..

Is your spark plug reach the correct lenght?.. often an overlooked item... if i remember, you did check that clearance.

Do you know that fuel pump octane can have huge octane variation? they don't guarantee 91 octane on the 91 pump....(maby try a different gas station.)

As for other tests beside ignition and fuel delivery... there's not many test that will tell the oil ring and valve seal sealing condition(that i know of)...

As for detonation sometime it can show as black spec only, .. the aluminum ones are when heavy detonation occur. in that case, you should really fix the problem before running it again.(any any case, you should never run an engine that has detonation..)

EDIT:

My previous 350 before the 383/blower rebuild had the exact same problem.. it was knocking under a certain load at a certain rpm on the highway in 4th gear. it ended fucking up all the crank/rod/cam bearing, then oil pressure dropped to 4 psi and started knocking at idle because of that. (Dont want to scare you, just be cautious..)

The problem was too much ignition advance on 87 octane.. or lack of experience from my part, call it whatever you want haha  .

.