reading thru this thread, brings back 40 plus years of memories on many dozens of individually build engines ,on the more memorable engines and reminds me of how I've succeeded and on occasion screwed up, on those occasion,s when I failed to do the research on how things were to be done correctly, or how they could be improved.

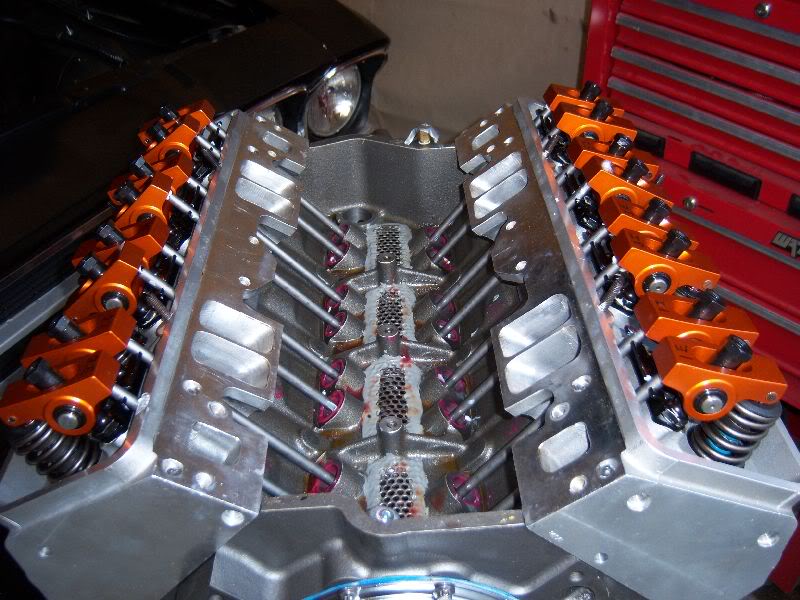

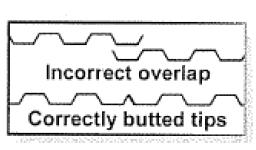

we all learn from our screw ups, and the smarter guys also learn from their buddies mistakes, and its surprising what you can do to improve durability by learning how to verify clearances and never assuming the machine shop actually did the work correctly, without checking and verifying every last clearance, or how a bit of time polishing or grinding or measuring makes, what most people assume is a minimal difference, while in reality those minimal differences combined add up to make a noticeable improvement in the finished results, and in both cases where any mistakes are made, if your smart you step back, and ask why did that happen, what can be done to prevent that, or how can that be done better, looking over the process, and whats been learned over time, makes it rather obvious WHY I never made any really money building engines and WHY I have a waiting list, of customers willing to wait to get an engine built....you just can,t build a quality engine taking all the detailed, and time intensive steps required , and charge even any where near a decent PER HOUR RATE, and be even vaguely competitively priced to factory crate engines, that come with a guarantee, now theres also no comparison the the quality of the finished product or horse power or durability but 99% of the customers are only looking at the price, horsepower and expected delivery time and never see whats involved in producing a quality product thats carefully assembled, you get a sense of pride when you hear an engine you built ran a bit better than the other guys, or when you see the engine you built for a friend is still running strong after 40K-50K miles , when you know their buddies running very similar cars and engines are on their 3rd or fourth rebuild

its also nice to know that your passing on the skills and knowledge to the few guys that will appreciate what it takes to build a really durable engine, so that in a sense all that experience is not limited or wasted on a single person or lost if something were to happen to that person , theres not much sense in more than one person making all the mistakes and doing all the research required to get things done if its easily available and documented for the few people that care, to do it correctly vs the vast majority who will continue to slap parts together , never measure a darn part or verify anything, assume the machine shop did everything correctly,and wonder why they have problems