given the info stated ,let me know what CRANE AND CROWER SUGGEST, but keep in mind for a street driven car will in most cases be much better matched to a cam thats maximizing the 1800rpm-6000rpm power band, and having a strong 3000rpm-6000rpm plus power band, peak horsepower is a bit less important in a street cars engine that having extended durability and a strong mid rpm torque curve

in an 1800 lb T-bucket ID SELECT SOMETHING SIMILAR TO THESE, with a 3000rpm-3200rpm stall converter, keep in mind your not trying to maximize just the peak horsepower numbers , having bragging rights and impressive peak horse power numbers is cool , but its having instantly responsive and massive torque that allows the car to destroy the tires at the blip of the throttle and still have the ability to cruise on trips that makes the car really fun to drive!

I've tried dozens of engine combos , and while every choice is a compromise in some area, you can build a very nice engine if you concentrate on massive mid rpm torque, and a power curve that allows you to produce that power in the 3000rpm-6400rpm power band.

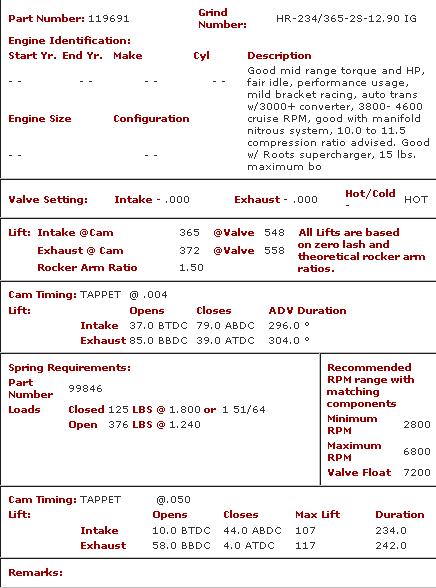

Id suggest you call crower and crane and talk to their tech guys, but youll be looking in the 232-245 degree intake duration @ .050 lift range in a hydraulic roller cam in an engine built to do what your looking to do, in most cases, I,d suggest the CRANE OR CROWER CAMS LINKED TO BELOW, as a good match to the application suggested...yes the cam suggested by crower , the #00426 is a solid roller cam, and it will without doubt produce better peak hp, but it will also be noticeably less street drive friendly,(especially if matched to an automatic transmission without a high stall converter, that will be mandatory to allow a cam with that much duration to function efficiently) so you'll need to decide what route to take and what your willing to compromise. keep in mind the cylinder heads, intake, manifold design, headers,displacement, compression ratio ETC. all effect the results, and you'll want to make some educated choices, but getting a selection of parts that will produce a wide power band, and rock solid durability, will be one key element to a good combo.

this info might be useful

http://www.brodix.com/heads/ikdyno.php

viewtopic.php?f=69&t=182&p=4788#p4788

http://www.brodix.com/heads/ik210dyno.php

http://www.cranecams.com/product/cart.p ... il&p=24191

386-310-4875

( crane 119691)

I'VE used this CROWER CAMS

00471 HYDRAULIC ROLLER ,SEVERAL TIMES IN PREVIOUS BUILDS WITH GOOD RESULTS

http://www.crower.com/chevy-262-400-ser ... ircle.html

Phone 619.661.6477

( crower 00471s)

Ive built at least 7, 383-and-406 SBC based engine builds now, in the last 10-12 years with darn near the exact same combo, of crower roller cam,similar brodix heads,similar compression,roller rockers and while the engines only differed in factors like the headers , ignitions,or intake manifold used I can,t remember any of them having any issues as long as premium octane fuel was used and all produced decent power in the rpm band your cars going to operate in,and they all worked in reasonably light cars,(under 3200lbs) to produce decent performance , some were automatics, most used a 3200 rpm stall converter and 3.73:1-to-3.90:1 rear gears and similar tire heights, you can drop the dynamic compression by re-indexing the cam to 2-4 degrees retarded from split over lap and youll generally pick up 200-300 rpm of useable power on the upper rpm range and loose a bit of off idle torque

viewtopic.php?f=44&t=10553&p=44949&hilit=retard+bushing#p44949

this is how as an engine builder you gain experience, in that you see the result of each change you make and look at how each components being selected or modified effects those results, and in most cases use that accumulated experience looking at those results to further refine ind improve the combo further, and yes once you find an exceptionally effective combo if your smart you take notes and record what worked best so in the future you can use that info

having a REV-KIT that retains the lifters in their bores, to maintain oil pressure, even if the rocker comes loose or push rods breaks is a good idea