Maniacmechanic1

solid fixture here in the forum

Use a Shop Vacuum cleaner Rick with a Nozzle attachment..

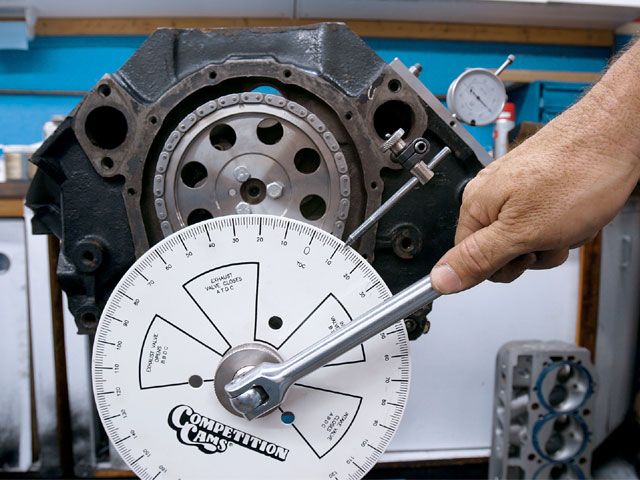

I've been cleaning the pistons to prepare for assembly. The photo below is something I did

trying and help to avoid more clean up. The carbon wants to fall into the water jackets or

the threaded head bolt holes.

View attachment 9458

The best way I've found to clean the piston tops is to use a scraper with a razor's edge. It does want

to dig in when you get the attach angle to high. Using a little finesse you can skim the top and have

a pretty clean top. Then use some Red scotchbrite to finish the job.

View attachment 9457

I'm open to suggestions for cleaning the cylinders. It's obviously that all one can do is push the carbon

down into the gap around the the piston.

I've thought that squirting some high viscous fluid around the perimeter of the piston, then turn the crank

so that the piston moves down. This should leave the crude on the cylinder wall so I can wipe it off. I don't

think there is anyway to wash it out, that won't force it past the pistons rings into the crankcase.

I'm looking for suggestions for cleaning above the piston and top ring.

View attachment 9456

.

.

Suck the carbon crud up best as you can.

Then wipe down the cylinders with Dextron III ATF.

Rotate the engine around by hand and stop every so often & wipe up the residual carbon left on the cylinder walls.

Then put 10w30 motor oil on a rag.

Squeeze the excess out. Then wipe down the cylinders to apply 10w30 Oil.

Rotate the crank again to get all 8 cylinders well oiled up.