Strictly Attitude

solid fixture here in the forum

Willing to bet from break in

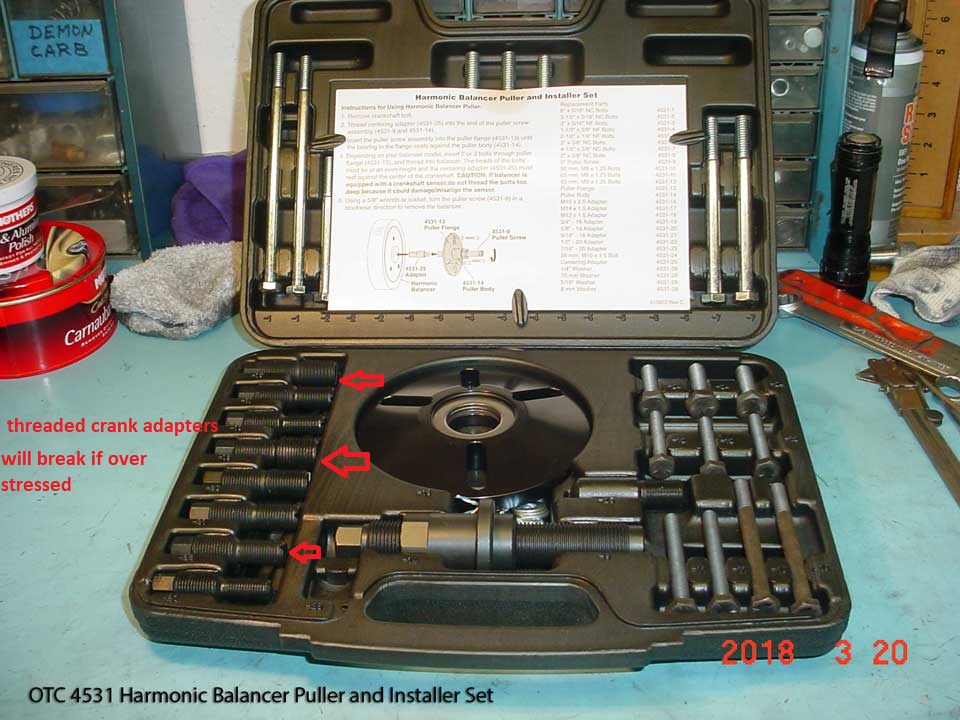

Thanks for that info, I might look into that. My bill is starting to add up now with the valveWell, you could get the very expensive one like this $210,

Please no more suggestions, I can't afford any more of them !!!Well, you could get the very expensive one like this $210,

I just did not want to travel back to O'Reilly's again, last time I didn't check before I went and had to go toyeah, there's no doubt at all that the number and cost of tools you need to accumulate ,

frequently come close too or at times even exceed the the number of parts you actually install on any properly built cars.

you obviously run the risk of eventually rationalizing the need to justify the tool obsession,

by building a new or second car to further make the purchase of the tools,

and learning all the related skills seem , like its rational.

its a bit like the reloading cartridges hobby.. there's always the need to upgrade tools,

and once you have the tools you might as well but a new revolver or rifles,

since ammo won,t cost much now that you have the tools.

tool junky , and hand loading,& engine building insanity,

is a infectious, communicable virus, you can even catch over the internet.

Ahh I found It.Sorry guys, I had to rest this 61 year old body of mine first!!! Well actually we

had to have onion burger at Sid's Diner in El Reno first and download the videos

to my computer, then prepare them for YouTube.

When I read Gumpy's post about all the info he wanted, including vacuum reading

and A/F ratio on both sides .... I'm thinking when in HELL am I suppose get time

to drive this thing while taking all those damn readings in 5 seconds. :lol:

As far the the Spark Plugs go, this is what I did. I waited until I got there, then

installed the new plugs, made 7-8 passes and then removed them. Took photos

and each bank, labeled them and put them back in the boxes. So if I need a better

photo later, I can always go back and take more, maybe with my 8x magnification.

Tomorrow I will the spark plug photos.

Below are the videos posted in the order they were run. I didn't post everyone of

them, but do have five different runs out of the 7-8 I made. Well I was going to

post them, but YouTube video stabilization processing is taking a long time.

I can post an run by a very wicked GTO.

Also a very nice Blown 55 Chevy vs a Mustang video.

I will follow up tomorrow with the videos, comments and spark plug pics.

As sure as I can be. Guess I could have called Harland Sharp. I made sure it was for 7/16 inch studs and SBC.You are sure that girdle works with your heads?

Yes, but the valve locations might be moved from standard location, commonly called a 60/40 split, IIRC.As sure as I can be. Guess I could have called Harland Sharp. I made sure it was for 7/16 inch studs and SBC.