Maniacmechanic1

solid fixture here in the forum

Ok.Taking this Thursday off to pull the trans.

John & Me both have to play Hookey from work Likewise at times.

Get our own stuff done Rick.

Just have to do It.

Ok.Taking this Thursday off to pull the trans.

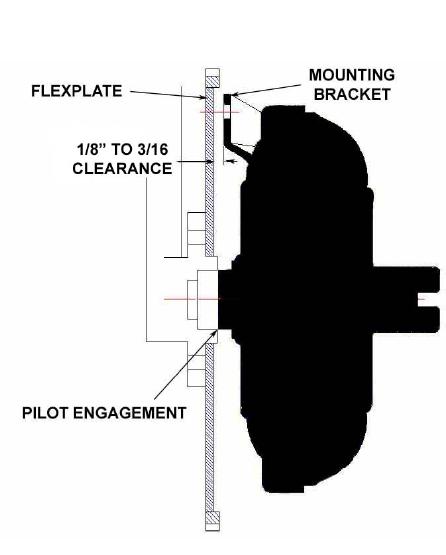

I will certainly be looking at that. I will have to make some decisions about just how far doyou might simply have a mis-aligned converter to crank recess engagement issue, causing at least some small part of that problem

I was recently asked if there was any benefit to adding transmission fluid additives to transmission fluid,

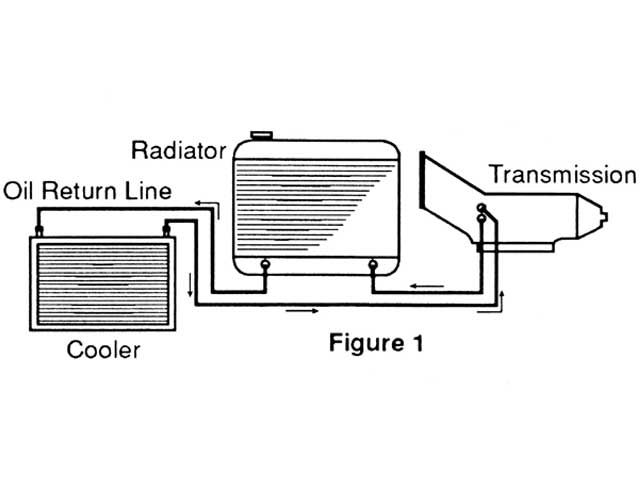

getting back too the original intent on the thread, I think adding a well designed transmission fluid cooler ,

transmission fluid like engine oil tends to degrade and accumulate micro crud that accelerated wear,

theres no additives you can add that will do as much good as,simply replacing the old worn transmission fluid,

and replacing the transmission filter occasionally.

and changing out the transmission filter and trans fluid too a good synthetic based fluid ,every 70K miles or so,

and use of a separate electrically fan cooled fluid cooling heat exchanger that will keep the fluid temps under 170F ,

will do more for most automatic transmissions long term durability than any additives will, do to help extend the service life of any existing high mileage and possibly over stressed and over heated transmission fluid.

measure very carefully youll need to mount the transmission cooler in a location that allows clearance for both the cooler and its supply lines and in a location with easy access to outside air flow so the heated air can rapidly be replaced with cooler outside air, for effective heat reduction to the fluid to effectively take place.

ID suggest no smaller than AN#8 line (1/2") size and a 24000 lb weight rated cooler if you have the room to mount one on a serious race application, with a high stall speed torque converter.

https://www.summitracing.com/parts/der-15850/overview/

https://www.summitracing.com/parts/der-15900/overview/

https://www.summitracing.com/parts/flx-45908/overview/

http://garage.grumpysperformance.co...info-and-derale-trans-cool-pans.662/#post-912

https://www.summitracing.com/parts/prm-13182/overview/

http://garage.grumpysperformance.co...l-cooler-increases-durability.176/#post-48374

http://garage.grumpysperformance.com/index.php?threads/replacing-trans-fluid.10749/#post-46958

http://garage.grumpysperformance.co...ans-cooler-on-a-c4-corvette.10514/#post-44478

http://garage.grumpysperformance.co...fo-and-derale-trans-cool-pans.662/#post-34937

http://garage.grumpysperformance.com/index.php?threads/hot-trans-smell.7704/#post-26227

http://garage.grumpysperformance.com/index.php?threads/transmission-fluid-filters.4910/#post-17143

http://garage.grumpysperformance.com/index.php?threads/flushing-a-transmission.5302/#post-15712

I swear by Stand Alone Massive Transmission Coolers now Grumpy.RICK??? I don,t remember off hand ,

did you install a separate trans fluid cooler with an electric fan,

too keep trans fluid cool,and a trans fluid temp gauge on the t-bucket?

Just saw this video Rick. Port alignment doesn't get any better than yours.Intake Manifold Port Inspection

RICK??? I don,t remember off hand ,

did you install a separate trans fluid cooler with an electric fan,

too keep trans fluid cool,and a trans fluid temp gauge on the t-bucket?

Heatsink style be Better On the T I think Rick.Yes I have a cooler installed with 1/2 inch lines and -8 AN fittings, but no fan. My biggest problem is

on the highway running 70 mph, not sure how much the fan would help there. But it certainly wouldn't

hurt either. Some duct work would be helpful to direct the air into the cooler.

View attachment 9872

View attachment 9871

View attachment 9873

Hey thanks for those kind words, glad you enjoyed the read.Very impressive and detailed work. It took me 4 days to read the whole project. Very good information.

That should never happen Rick.Great Big Thanks to John (JohnHancock) for coming over last night and helping get the trans out !!!

With the trans out, it was very clear why the torque converter TC would not go back into the crank and

mate up with the flexplate.

How critical is the snouts dimensions and concentricity. Can I use a cartridge roll and and smooth out

the edges until it fits into the back of the crank???

.

View attachment 9879

View attachment 9881

View attachment 9880

View attachment 9882

.

Yes Rick.