I get several guys asking me every month about how you go about learning to weld, and the truth is theres a dozen ways to go about learning and it sure helps if you have a local trade school or some other place you can get skilled instructions, but its far from mandatory now that the internet has so much info available.

Now the first thing Im forced to point out is that cheap, crappy equipment just leads to far more frustration than the cost savings will come close to justifying, so Id strongly advise getting some decent equipment to start out with, like

MILLER,HOBART,LINCOLN,ETC. and by far the easiest welders to learn on are most likely a good MIG welder in the 140-210 amp range, and don,t forget you NEED to have the correct safety equipment , and a welding apron, gloves and a self darkening face mask is where you start,and a tank of shield gas is MANDATORY to mig weld.(depends on your goals)

and its PRACTICE and getting in there and making mistakes and seeing what will and will not work that builds the required skill.

you can go to a local muffler shop or metal supply and ask for or in some cases buy small scrap pieces of angle iron, exhaust pipe, old metal brackets etc, and use those to learn on, while you gain some skill at running a bead, setting the amp range, gas flow rates and learn how to build a puddle of molten metal and get it to penetrate without burning thru the parent metal.

most new welders from quality suppliers come with an instruction booklet, charts and in some cases an instructional video, which can be rather helpful. theres also a great many videos currently on the internet to help you learn.

now your not going to make great welds for several hours or days so don,t get frustrated, its a skill, and it takes all of us time to acquire that skill, some of us will just be faster at picking it up than others but anyone can eventually master MIG welding, as my college instructor used to say

" they can teach moneys to mig weld, so you guys have at least some chance at learning the skill"

trust me when I say that a quality WELDER and a decent vise and a drill press are MANDATORY BASIC REQUIRED tools

Im often asked why I prefer the TIG and oxy-acetolene torch welding over arc and mig for most jobs and the reasons that with both those types of equipment you can heat, reheat or adjust the heat nearly instantly with or without adding filler rod material.

that might not sound like a huge advantage, but trust me here its critical at times, do your research, you'll find you have options, in accessories and materials, the choices you make , make a big difference in how versatile or easy to use the welder becomes in your shop

youll gain a great deal of experience and skill with the welder as you practice,

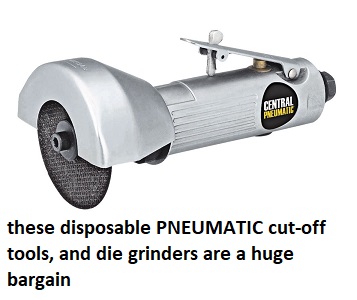

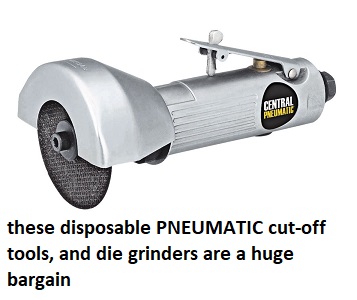

and youll eventually find a die grinder and carbide cut-off wheel handy for removing ,

the minor welds in that progress youll have made.

https://www.harborfreight.com/3-in-high-speed-air-cut-off-tool-60243.html

https://www.harborfreight.com/3-in-...el-10-pc-61180.html?_br_psugg_q=cut+off+wheel

each has its use and the deeper you get into the hobby the more youll use a welder and a drill press

HERES THE MIG I PURCHASED

MILLER 252

http://www.welders-direct.com/mm5/merch ... gory_Code=

FOR MY SHOP, (IT COST $2200 AT THAT TIME) IT HAS AN OPTIONAL KIT THAT WILL ALLOW YOU TO MIG ALUMINUM< BUT ITS RATHER EXPENSIVE

(about $1100 BACK THEN)

http://www.welders-direct.com/mm5/merch ... ode=130831

but its a TOP QUALITY MIG THAT WILL HANDLE 95% OF AUTOMOTIVE WELDING IF YOU GET THE OPTIONAL KIT

PRICES HAVE INCREASED NOTICEABLY SINCE THEN

YOULL FIND YOU WILL RARELY REGRET BUYING QUALITY WELDERS OR ACCESSORIES

HAVING A WORKING WELDING TABLE IS NOT MANDATORY BUT YOULL WONDER HOW ANYONE CAN WORK WITHOUT A DECENT VISE AND WORK BENCH, AND A SOLID METAL BENCH HAS BENEFITS FOR USE AS A WELDING LOCATION.

I purchased a 30 year old used TIG welder , water cooled torch and foot petal assembly ,myself ,and while its hardly state of the art it does weld well. TIG is far more controllable as you can control arc heat, feed rates,on both the arc and fill rod , each separately , and can go back over welds and re-heat without adding, or adding fill rod all you want, so IM hardly going to suggest you need the newest version to get decent tig welds, while its slower its also far more flexible in what you can do or redo, now having used some of the newer TIG welders I will say they have advantages,you don,t necessarily need the latest and best to weld, keep in mind older equipment is not necessarily bad or obsolete, it just might not have the latest features

kind of like dating a 40 year old girl,when your both out looking to have a good time, she might not look as nice as a 19 year old but she has experience, style and probably can get the job done really well just the same

related useful links, you should read thru.

related useful links, you should read thru.

http://www.mig-welding.co.uk/tutorial.htm

http://www.mig-welding.co.uk/

http://garage.grumpysperformance.co...-diy-project-video-well-worth-watching.15647/

http://www.usaweld.com/TIG-WELDER-Invertig-221-Welder-p/70221-12.5-1.htm

http://www.bing.com/videos/search?q=LEA ... &FORM=VDRE

http://www.usaweld.com/Learn-How-to-MIG-Weld-s/416.htm

http://www.amazon.com/Learn-Mig-Weld-We ... B006MHNLVA

http://www.instructables.com/id/How-to- ... G-Welding/

http://www.weldplus.com/tig-welders.htm

Now the first thing Im forced to point out is that cheap, crappy equipment just leads to far more frustration than the cost savings will come close to justifying, so Id strongly advise getting some decent equipment to start out with, like

MILLER,HOBART,LINCOLN,ETC. and by far the easiest welders to learn on are most likely a good MIG welder in the 140-210 amp range, and don,t forget you NEED to have the correct safety equipment , and a welding apron, gloves and a self darkening face mask is where you start,and a tank of shield gas is MANDATORY to mig weld.(depends on your goals)

and its PRACTICE and getting in there and making mistakes and seeing what will and will not work that builds the required skill.

you can go to a local muffler shop or metal supply and ask for or in some cases buy small scrap pieces of angle iron, exhaust pipe, old metal brackets etc, and use those to learn on, while you gain some skill at running a bead, setting the amp range, gas flow rates and learn how to build a puddle of molten metal and get it to penetrate without burning thru the parent metal.

most new welders from quality suppliers come with an instruction booklet, charts and in some cases an instructional video, which can be rather helpful. theres also a great many videos currently on the internet to help you learn.

now your not going to make great welds for several hours or days so don,t get frustrated, its a skill, and it takes all of us time to acquire that skill, some of us will just be faster at picking it up than others but anyone can eventually master MIG welding, as my college instructor used to say

" they can teach moneys to mig weld, so you guys have at least some chance at learning the skill"

trust me when I say that a quality WELDER and a decent vise and a drill press are MANDATORY BASIC REQUIRED tools

Im often asked why I prefer the TIG and oxy-acetolene torch welding over arc and mig for most jobs and the reasons that with both those types of equipment you can heat, reheat or adjust the heat nearly instantly with or without adding filler rod material.

that might not sound like a huge advantage, but trust me here its critical at times, do your research, you'll find you have options, in accessories and materials, the choices you make , make a big difference in how versatile or easy to use the welder becomes in your shop

youll gain a great deal of experience and skill with the welder as you practice,

and youll eventually find a die grinder and carbide cut-off wheel handy for removing ,

the minor welds in that progress youll have made.

https://www.harborfreight.com/3-in-high-speed-air-cut-off-tool-60243.html

https://www.harborfreight.com/3-in-...el-10-pc-61180.html?_br_psugg_q=cut+off+wheel

each has its use and the deeper you get into the hobby the more youll use a welder and a drill press

HERES THE MIG I PURCHASED

MILLER 252

http://www.welders-direct.com/mm5/merch ... gory_Code=

FOR MY SHOP, (IT COST $2200 AT THAT TIME) IT HAS AN OPTIONAL KIT THAT WILL ALLOW YOU TO MIG ALUMINUM< BUT ITS RATHER EXPENSIVE

(about $1100 BACK THEN)

http://www.welders-direct.com/mm5/merch ... ode=130831

but its a TOP QUALITY MIG THAT WILL HANDLE 95% OF AUTOMOTIVE WELDING IF YOU GET THE OPTIONAL KIT

PRICES HAVE INCREASED NOTICEABLY SINCE THEN

YOULL FIND YOU WILL RARELY REGRET BUYING QUALITY WELDERS OR ACCESSORIES

HAVING A WORKING WELDING TABLE IS NOT MANDATORY BUT YOULL WONDER HOW ANYONE CAN WORK WITHOUT A DECENT VISE AND WORK BENCH, AND A SOLID METAL BENCH HAS BENEFITS FOR USE AS A WELDING LOCATION.

I purchased a 30 year old used TIG welder , water cooled torch and foot petal assembly ,myself ,and while its hardly state of the art it does weld well. TIG is far more controllable as you can control arc heat, feed rates,on both the arc and fill rod , each separately , and can go back over welds and re-heat without adding, or adding fill rod all you want, so IM hardly going to suggest you need the newest version to get decent tig welds, while its slower its also far more flexible in what you can do or redo, now having used some of the newer TIG welders I will say they have advantages,you don,t necessarily need the latest and best to weld, keep in mind older equipment is not necessarily bad or obsolete, it just might not have the latest features

kind of like dating a 40 year old girl,when your both out looking to have a good time, she might not look as nice as a 19 year old but she has experience, style and probably can get the job done really well just the same

http://www.mig-welding.co.uk/tutorial.htm

http://www.mig-welding.co.uk/

http://garage.grumpysperformance.co...-diy-project-video-well-worth-watching.15647/

http://www.usaweld.com/TIG-WELDER-Invertig-221-Welder-p/70221-12.5-1.htm

http://www.bing.com/videos/search?q=LEA ... &FORM=VDRE

http://www.usaweld.com/Learn-How-to-MIG-Weld-s/416.htm

http://www.amazon.com/Learn-Mig-Weld-We ... B006MHNLVA

http://www.instructables.com/id/How-to- ... G-Welding/

http://www.weldplus.com/tig-welders.htm

Last edited by a moderator: