NOT A TA

reliable source of info

I know there's been a lot of discussions about the shift knob. Have a couple buds with real 70 TA's.

I've never seen this snowflake manifold either. My shaker's a later one but still the early 70-76 style that's open.

Moving along with aerodynamic modifications I'm currently working on the front end treatment.

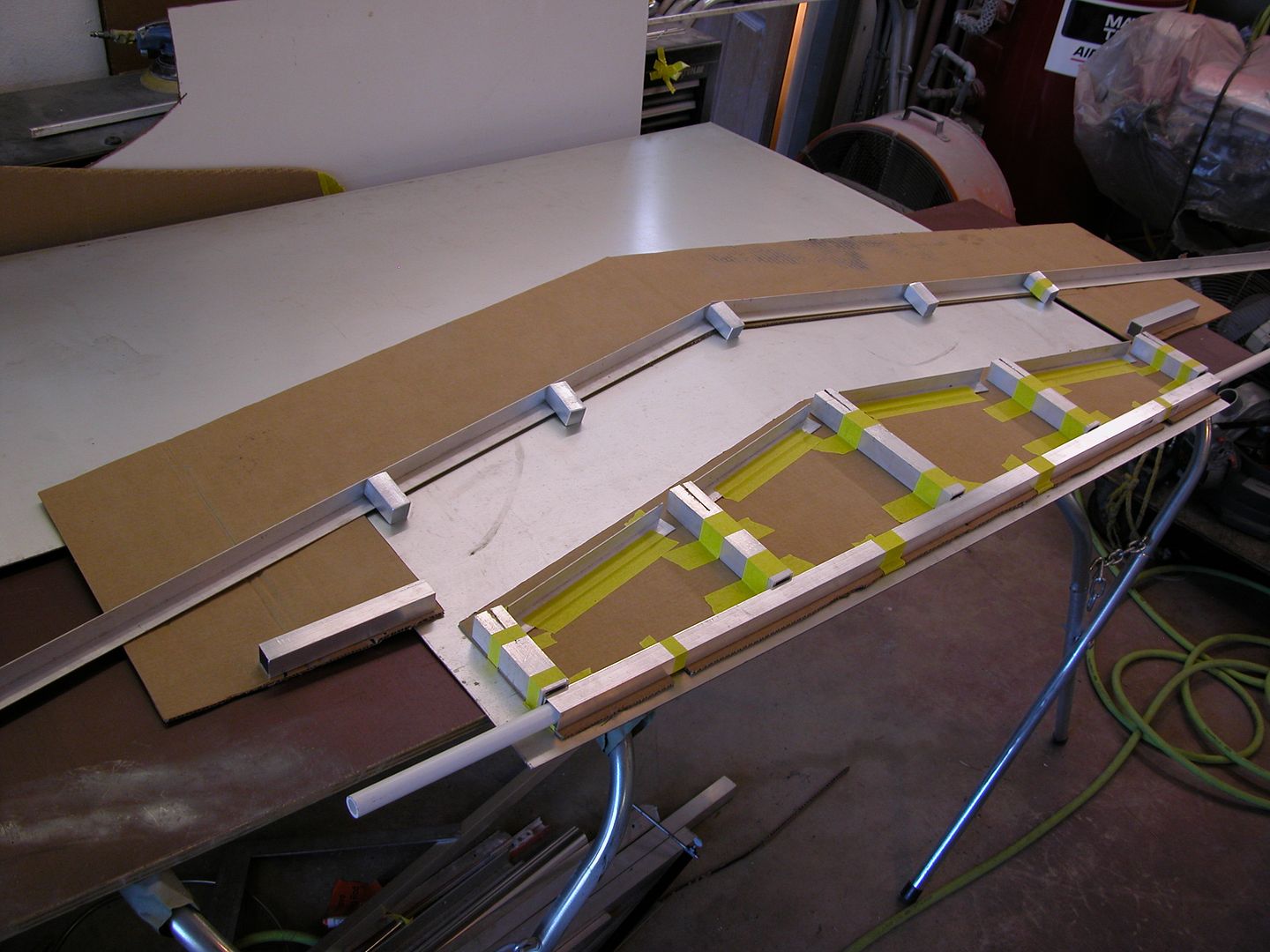

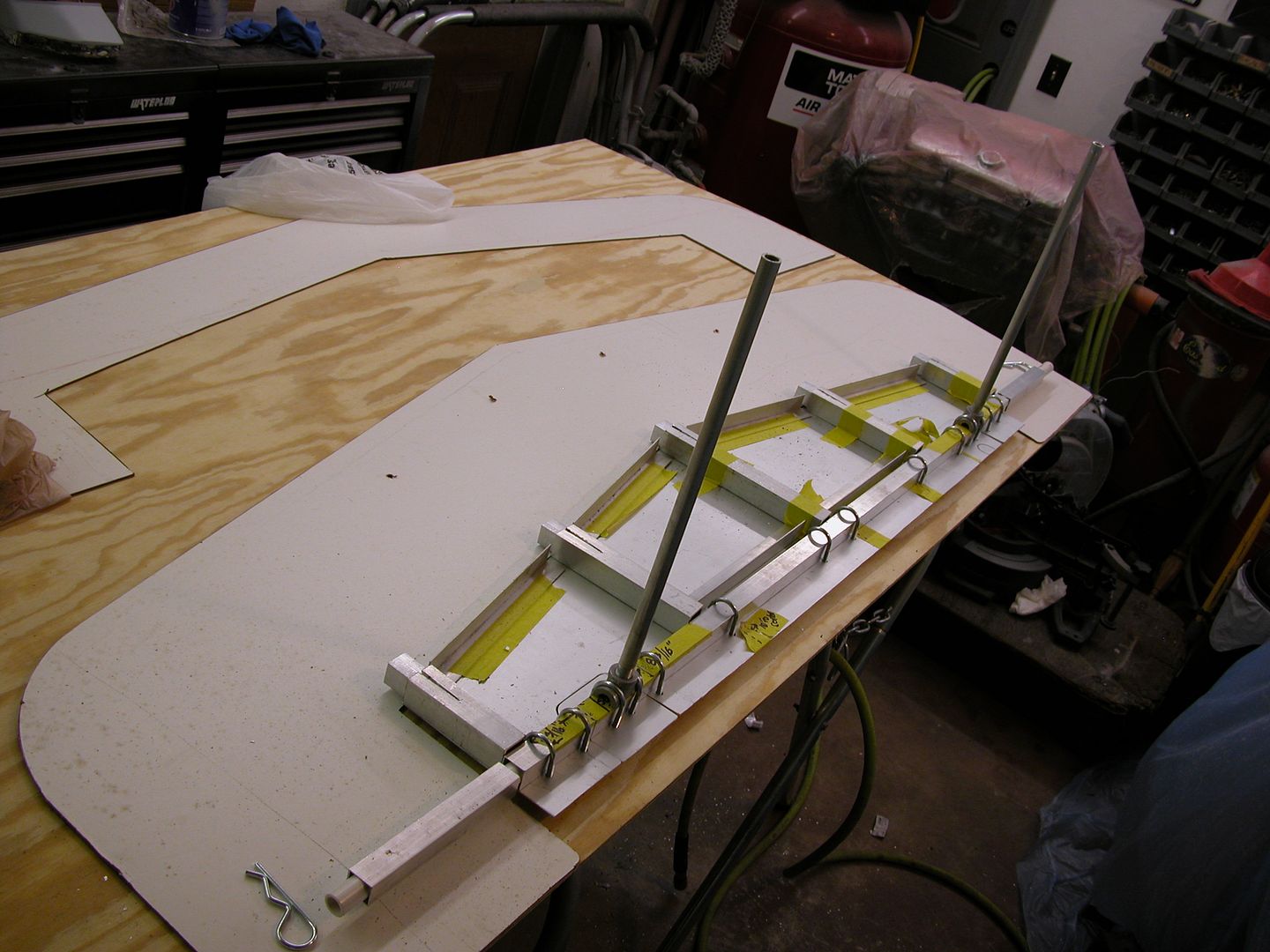

The splitter/tray/air dam combination I've got in mind is a bit unusual from those I've seen on other cars.

A. Hinged to allow the splitter to be pushed up if I hit corner curbing or something. Splitter could rise till it hits the stock air dam. I've never whacked the stock air dam and I'll probably only loose maybe 1/2" ground clearance.

B. Two piece splitter/tray so I can have various splitters that stick out more or less with the biggest reaching out as far as the leading edge of the bumper and out as wide as the wickers on the wheel flares.

C. Height adjustable so I can use for street, LSR, Drag strip, road course, or open road with various height air dam extensions.

D. Various air dam extensions that will fold up if the splitter gets pushed up. Probably three versions, small for drag race & street , medium for road tracks, and a deep air dam extension with minimal ground clearance for LSR with no splitter but supported from behind by the tray section.

E. Breakaway provisions so if something bad happens, damage to the car would be minimal and hopefully confined to the splash pan and stock air dam/wheel flares.

F. Cheap/replaceable using as many pieces of scraps left from other projects and junk people gave me as I can. I gathered all the stuff I've been collecting and figured I could make something out of it even if just a prototype. It'll get the scraps out of my way and hopefully save me a few bucks.

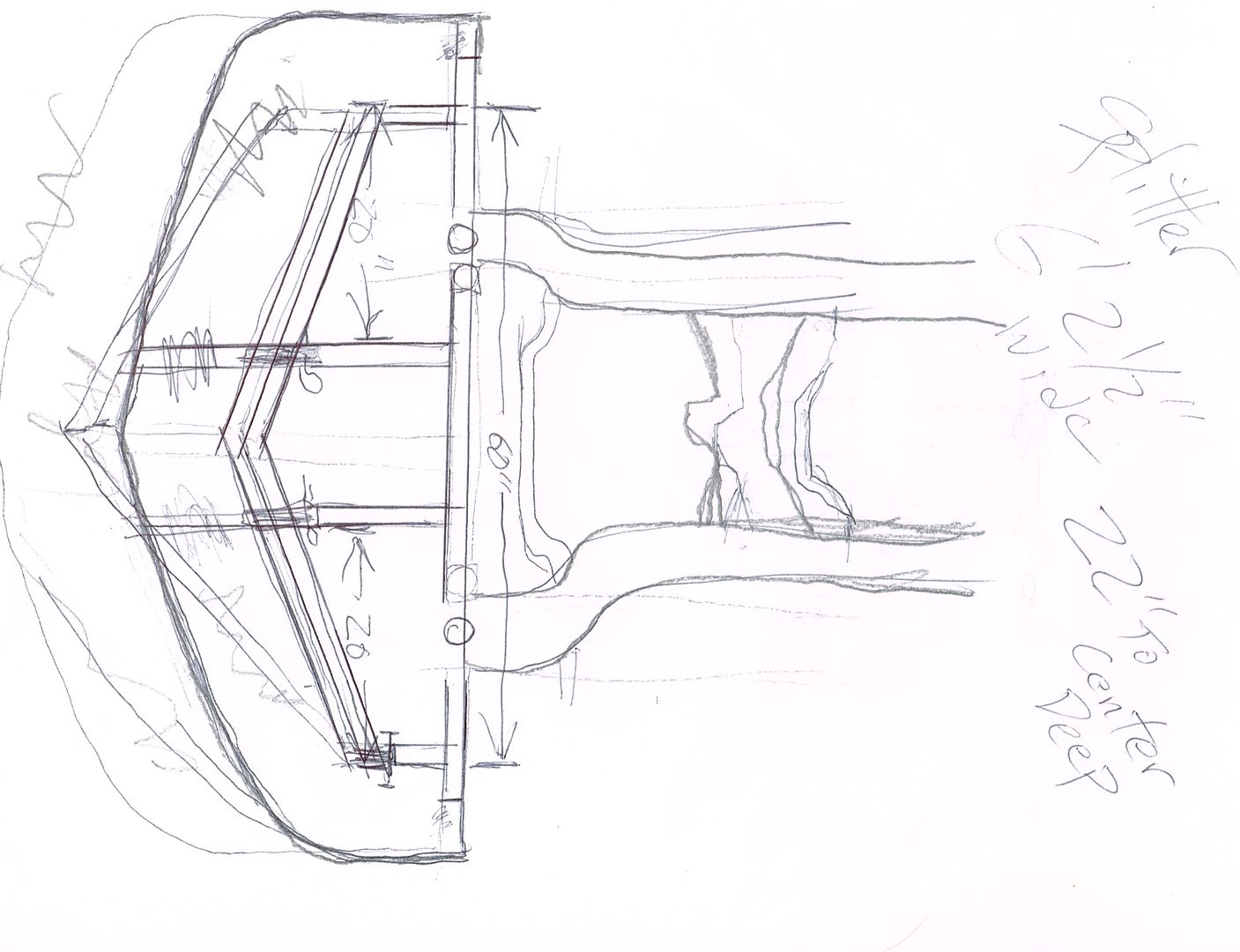

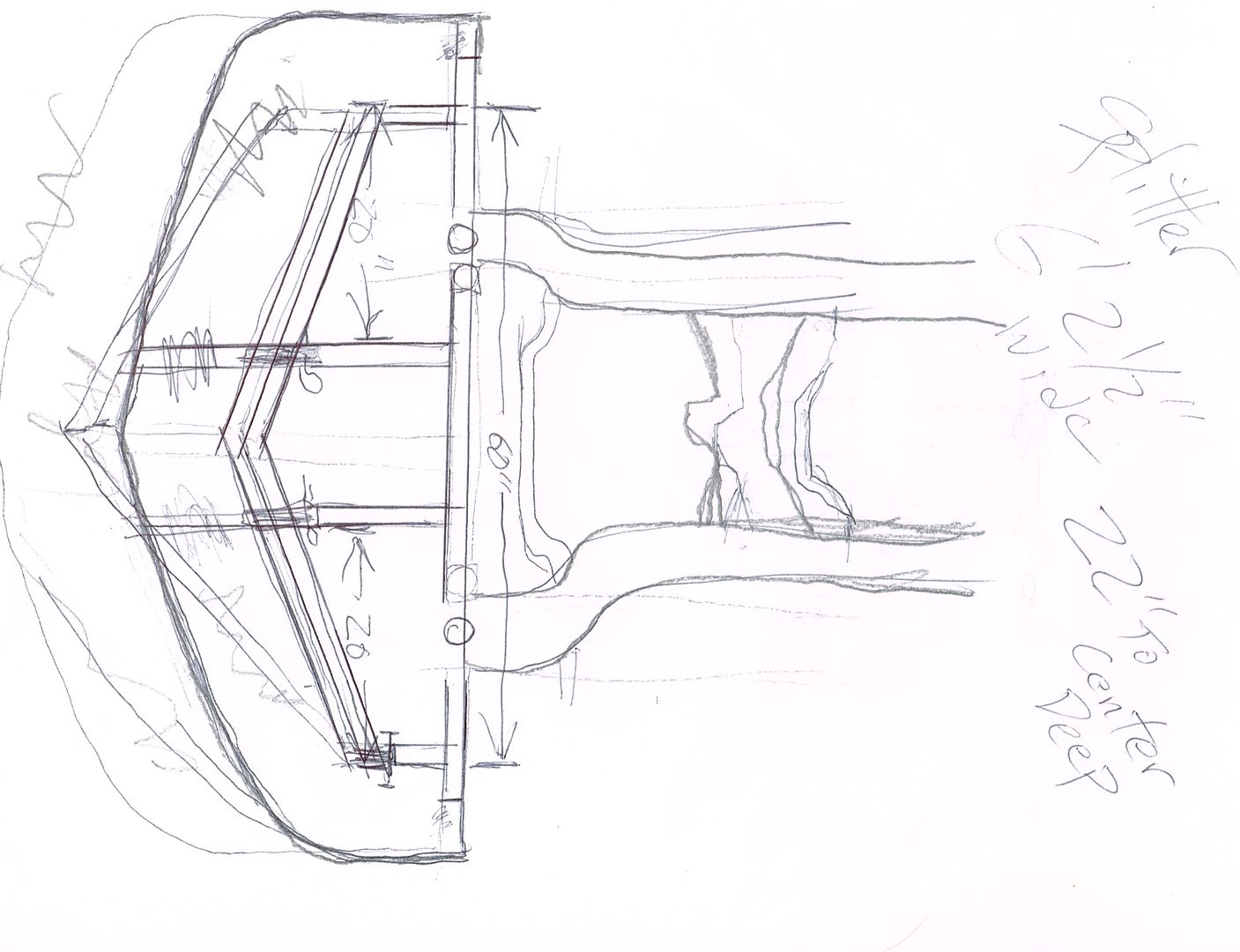

While today lots of folks use CAD I still use DIG (Draw In Garage) for projects like this. Here's the basic concept drawing. The tray section the various splitters will be attached to has a smaller footprint than the stock air dam/wheel flare section.

I've never seen this snowflake manifold either. My shaker's a later one but still the early 70-76 style that's open.

Moving along with aerodynamic modifications I'm currently working on the front end treatment.

The splitter/tray/air dam combination I've got in mind is a bit unusual from those I've seen on other cars.

A. Hinged to allow the splitter to be pushed up if I hit corner curbing or something. Splitter could rise till it hits the stock air dam. I've never whacked the stock air dam and I'll probably only loose maybe 1/2" ground clearance.

B. Two piece splitter/tray so I can have various splitters that stick out more or less with the biggest reaching out as far as the leading edge of the bumper and out as wide as the wickers on the wheel flares.

C. Height adjustable so I can use for street, LSR, Drag strip, road course, or open road with various height air dam extensions.

D. Various air dam extensions that will fold up if the splitter gets pushed up. Probably three versions, small for drag race & street , medium for road tracks, and a deep air dam extension with minimal ground clearance for LSR with no splitter but supported from behind by the tray section.

E. Breakaway provisions so if something bad happens, damage to the car would be minimal and hopefully confined to the splash pan and stock air dam/wheel flares.

F. Cheap/replaceable using as many pieces of scraps left from other projects and junk people gave me as I can. I gathered all the stuff I've been collecting and figured I could make something out of it even if just a prototype. It'll get the scraps out of my way and hopefully save me a few bucks.

While today lots of folks use CAD I still use DIG (Draw In Garage) for projects like this. Here's the basic concept drawing. The tray section the various splitters will be attached to has a smaller footprint than the stock air dam/wheel flare section.